Product Description

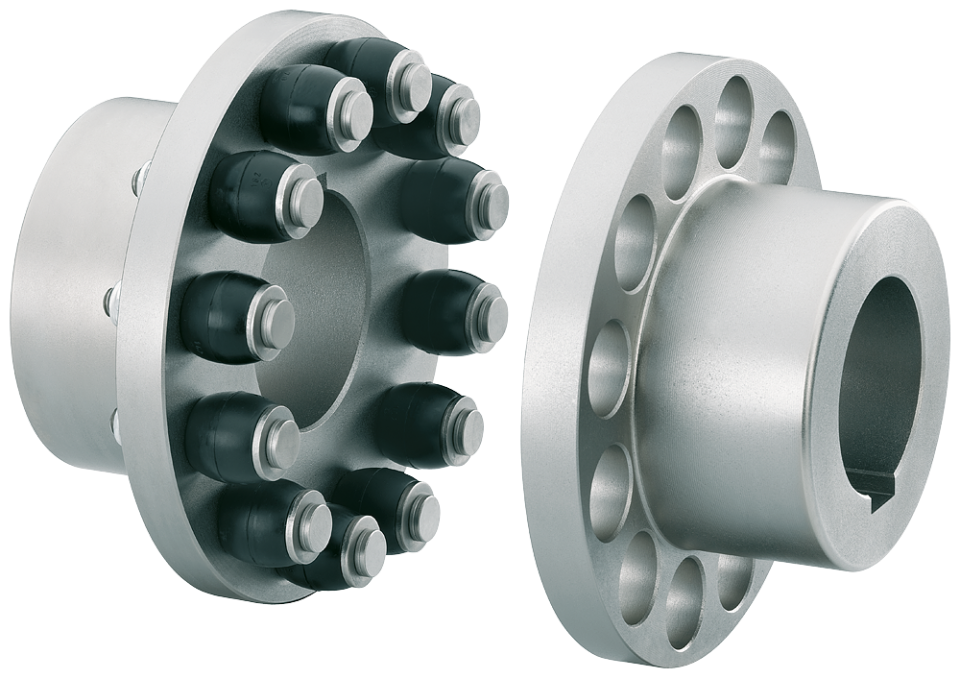

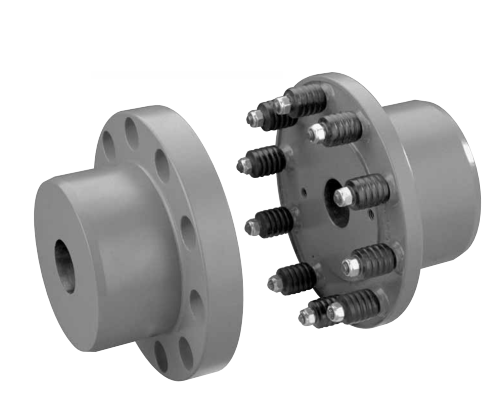

Cast Iron Elastic Pump Shaft Fcl 90~630 Reduced Transmission Rubber Screw Coupling with flange straight bore

Product Description

FCL coupling is widely used for its compact designing,easy installation,convenientmaintenance,small size and light weight.As long as the’relative displacement between shafts is kept within the specified tolerance,the coupling will operate the best function and a longer working life,thus it is greatly demanded in medium and minorpower transmission systems drive by moters,such as speed reducers,hoists,compressor,spining &weaving machines and ball mills,permittable relative displacement:Radial displacement 0.2-0.6mm ; Angel displacemente 0o30′–1o30′

Related products:

Production workshop:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can Pin Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, pin couplings can be used in both horizontal and vertical shaft arrangements. These couplings are designed to accommodate angular misalignment, parallel misalignment, and axial movement, making them versatile for various shaft orientations.

In horizontal shaft arrangements, where the shafts are aligned on the same horizontal plane, pin couplings can efficiently transmit torque while allowing for flexibility to accommodate minor misalignments and shaft movements. The pins and flexible elements in the coupling enable angular displacement and radial flexibility, ensuring smooth power transmission even if the shafts are not perfectly aligned.

In vertical shaft arrangements, where the shafts are aligned on a vertical plane, pin couplings can also be used effectively. The coupling design allows for axial movement, which is crucial in vertical applications where the shafts may experience expansion or contraction due to thermal changes or other factors. The flexible nature of pin couplings allows them to handle these axial movements without compromising the coupling’s performance.

Whether in horizontal or vertical arrangements, pin couplings are commonly used in various industrial applications, including pumps, compressors, conveyors, and other rotating machinery. They are known for their simplicity, ease of installation, and ability to provide reliable power transmission while accommodating misalignment and shaft movement.

When using pin couplings in either arrangement, it is essential to ensure proper alignment and regular maintenance to maximize their performance and service life. Additionally, considering factors like torque requirements, operating conditions, and environmental considerations will help in selecting the appropriate pin coupling for a specific application.

What Industries Commonly Use Pin Couplings for Power Transmission?

Pin couplings are widely used in various industries for power transmission due to their ability to accommodate misalignment and provide reliable torque transmission. Some of the industries where pin couplings are commonly employed include:

- 1. Manufacturing: In manufacturing processes, pin couplings are used in conveyor systems, mixers, agitators, and other machinery to transfer power between motors and driven equipment.

- 2. Pulp and Paper: The pulp and paper industry uses pin couplings in machinery such as pumps, fans, and rotary kilns for continuous power transmission.

- 3. Chemical and Petrochemical: Pin couplings find applications in chemical processing plants, refineries, and petrochemical facilities for various rotating equipment.

- 4. Water and Wastewater: Pin couplings are used in water treatment facilities, pumps, and blowers to transfer power efficiently.

- 5. Steel and Metal Processing: Steel mills and metal processing plants utilize pin couplings in rolling mills, extruders, and other equipment.

- 6. Food and Beverage: Pin couplings are employed in food processing machinery, packaging equipment, and conveyor systems.

- 7. Mining and Quarrying: The mining industry uses pin couplings in crushers, conveyor belts, and various mineral processing equipment.

- 8. Oil and Gas: Pin couplings are used in the oil and gas sector for pumps, compressors, and drilling equipment.

- 9. Power Generation: In power plants, pin couplings are used in turbines, generators, and other power transmission systems.

- 10. Construction and Heavy Equipment: Pin couplings find applications in construction machinery, earthmoving equipment, and other heavy-duty machinery.

- 11. Agriculture: In agricultural machinery, pin couplings are used in tractors, irrigation systems, and grain processing equipment.

These are just some examples of the industries where pin couplings are commonly used. Pin couplings offer versatility, ease of installation, and reliability, making them suitable for a wide range of applications in different sectors where power transmission is essential.

Advantages of Using Pin Couplings in Mechanical Systems

Pin couplings, also known as shear pin couplings, offer several advantages when used in mechanical systems. These advantages make them a popular choice for various industrial applications:

- 1. Overload Protection: Pin couplings are designed to provide overload protection to connected equipment. In case of excessive torque or sudden shock loads, the sacrificial pins will shear off, preventing damage to the shafts and other components.

- 2. Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts. This helps to compensate for minor misalignments and reduces the stress on the connected equipment.

- 3. Cost-Effective: The shear pins used in pin couplings are relatively inexpensive compared to other coupling components. In the event of a failure, replacing the damaged pins is a cost-effective solution, avoiding more significant repairs to the main equipment.

- 4. Easy Replacement: After shearing, the damaged pins can be quickly and easily replaced. This leads to reduced downtime and lower maintenance costs in the long run.

- 5. Versatility: Pin couplings are suitable for a wide range of applications, including pumps, compressors, fans, and other industrial machinery. Their ability to handle varying operating conditions makes them versatile in different environments.

- 6. Shock Load Absorption: Pin couplings can absorb and dissipate shock loads effectively. The shear pins act as a buffer, protecting the equipment from sudden impacts or overloads.

Despite their numerous advantages, it is essential to consider the limitations of pin couplings as well. They have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings. Additionally, the need to replace shear pins after each failure may lead to more frequent maintenance requirements in applications with frequent overloads or misalignments.

In conclusion, pin couplings provide reliable torque transmission and safety features, making them a valuable component in various mechanical systems. Their ability to protect against overloads and accommodate misalignments makes them a practical choice in a wide range of industrial applications.

editor by CX 2024-05-08

China FCL Flexible Shaft Couplings for Gearbox and Motor Screw Coupling Transmission Shaft Coupling for Spinning and Weaving Machines manufacturer

Merchandise Description

FCL Adaptable Shaft Couplings for Gearbox and Motor Screw Coupling Transmission Shaft Coupling for Spinning and Weaving Equipment

Characteristics

- Compact developing, effortless set up.

- Practical maintenance, small dimension, and lightweight.

- Commonly utilized in medium and small energy transmission techniques pushed by motors, this kind of as speed reducers, hoists, compressors, conveyors, sp

Item Description

| Measurement | N.m | r/min |

D | D1 | d1 | L | C | n-M | kg | |

| FCL90 | 4 | 4000 | ninety | 35.five | eleven | 28 | three | four-M8 | one.7 | |

| FCL100 | ten | 4000 | 100 | 40 | 11 | 35.five | three | 4-M10 | 2.3 | |

| FCL112 | 16 | 4000 | 112 | 45 | 13 | forty | three | four-M10 | two.8 | |

| FCL125 | 25 | 4000 | a hundred twenty five | sixty five | fifty | thirteen | forty five | 3 | 4-M12 | 4 |

| FCL140 | fifty | 4000 | a hundred and forty | seventy one | sixty three | 13 | fifty | three | six-M12 | 5.four |

| FCL160 | 110 | 4000 | 160 | 80 | 15 | fifty six | three | 8-M12 | eight | |

| FCL180 | 157 | 3500 | 180 | 90 | 15 | sixty three | 3 | 8-M12 | 10.5 | |

| FCL200 | 245 | 3200 | 200 | 100 | 21 | 71 | 4 | eight-M20 | 16.2 | |

| FCL224 | 392 | 2850 | 224 | 112 | 21 | eighty | 4 | eight-M20 | 21.three | |

| FCL250 | 618 | 2550 | 250 | 125 | twenty five | ninety | four | 8-M24 | 31.six | |

| FCL280 | 980 | 2300 | 280 | 140 | 34 | one hundred | 4 | eight-M24 | forty four | |

| FCL315 | 1568 | 2050 | 315 | 160 | forty one | 112 | four | 10-M24 | fifty seven.7 | |

| FCL355 | 2450 | 1800 | 355 | 180 | 60 | one hundred twenty five | 5 | 8-M30 | 89.5 | |

| FCL400 | 3920 | 1600 | 400 | 200 | sixty | one hundred twenty five | 5 | ten-M30 | 113 | |

| FCL450 | 6174 | 1400 | 450 | 224 | sixty five | 140 | 5 | twelve-M30 | a hundred forty five | |

| FCL560 | 9800 | 1150 | 560 | 250 | eighty five | 160 | 5 | fourteen-M30 | 229 | |

| FCL630 | 15680 | 1000 | 630 | 280 | 95 | a hundred and eighty | five | 18-M30 | 296 | |

Relevant Products

Company Profile

FAQ

Q: How to ship to us?

A: It is offered by air, sea, or train.

Q: How to spend the funds?

A: T/T and L/C are desired, with distinct currencies, like USD, EUR, RMB, and many others.

Q: How can I know if the product is suitable for me?

A: >1ST verify drawing and specification >2nd check sample >3rd start mass production.

Q: Can I come to your firm to check out?

A: Yes, you are welcome to pay a visit to us at any time.

|

US $5 / Piece | |

1,000 Pieces (Min. Order) |

###

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 11-95 |

| Torque: | >80N.M |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| SIZE | N.m | r/min |

D | D1 | d1 | L | C | n-M | kg | |

| FCL90 | 4 | 4000 | 90 | 35.5 | 11 | 28 | 3 | 4-M8 | 1.7 | |

| FCL100 | 10 | 4000 | 100 | 40 | 11 | 35.5 | 3 | 4-M10 | 2.3 | |

| FCL112 | 16 | 4000 | 112 | 45 | 13 | 40 | 3 | 4-M10 | 2.8 | |

| FCL125 | 25 | 4000 | 125 | 65 | 50 | 13 | 45 | 3 | 4-M12 | 4 |

| FCL140 | 50 | 4000 | 140 | 71 | 63 | 13 | 50 | 3 | 6-M12 | 5.4 |

| FCL160 | 110 | 4000 | 160 | 80 | 15 | 56 | 3 | 8-M12 | 8 | |

| FCL180 | 157 | 3500 | 180 | 90 | 15 | 63 | 3 | 8-M12 | 10.5 | |

| FCL200 | 245 | 3200 | 200 | 100 | 21 | 71 | 4 | 8-M20 | 16.2 | |

| FCL224 | 392 | 2850 | 224 | 112 | 21 | 80 | 4 | 8-M20 | 21.3 | |

| FCL250 | 618 | 2550 | 250 | 125 | 25 | 90 | 4 | 8-M24 | 31.6 | |

| FCL280 | 980 | 2300 | 280 | 140 | 34 | 100 | 4 | 8-M24 | 44 | |

| FCL315 | 1568 | 2050 | 315 | 160 | 41 | 112 | 4 | 10-M24 | 57.7 | |

| FCL355 | 2450 | 1800 | 355 | 180 | 60 | 125 | 5 | 8-M30 | 89.5 | |

| FCL400 | 3920 | 1600 | 400 | 200 | 60 | 125 | 5 | 10-M30 | 113 | |

| FCL450 | 6174 | 1400 | 450 | 224 | 65 | 140 | 5 | 12-M30 | 145 | |

| FCL560 | 9800 | 1150 | 560 | 250 | 85 | 160 | 5 | 14-M30 | 229 | |

| FCL630 | 15680 | 1000 | 630 | 280 | 95 | 180 | 5 | 18-M30 | 296 | |

|

US $5 / Piece | |

1,000 Pieces (Min. Order) |

###

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 11-95 |

| Torque: | >80N.M |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| SIZE | N.m | r/min |

D | D1 | d1 | L | C | n-M | kg | |

| FCL90 | 4 | 4000 | 90 | 35.5 | 11 | 28 | 3 | 4-M8 | 1.7 | |

| FCL100 | 10 | 4000 | 100 | 40 | 11 | 35.5 | 3 | 4-M10 | 2.3 | |

| FCL112 | 16 | 4000 | 112 | 45 | 13 | 40 | 3 | 4-M10 | 2.8 | |

| FCL125 | 25 | 4000 | 125 | 65 | 50 | 13 | 45 | 3 | 4-M12 | 4 |

| FCL140 | 50 | 4000 | 140 | 71 | 63 | 13 | 50 | 3 | 6-M12 | 5.4 |

| FCL160 | 110 | 4000 | 160 | 80 | 15 | 56 | 3 | 8-M12 | 8 | |

| FCL180 | 157 | 3500 | 180 | 90 | 15 | 63 | 3 | 8-M12 | 10.5 | |

| FCL200 | 245 | 3200 | 200 | 100 | 21 | 71 | 4 | 8-M20 | 16.2 | |

| FCL224 | 392 | 2850 | 224 | 112 | 21 | 80 | 4 | 8-M20 | 21.3 | |

| FCL250 | 618 | 2550 | 250 | 125 | 25 | 90 | 4 | 8-M24 | 31.6 | |

| FCL280 | 980 | 2300 | 280 | 140 | 34 | 100 | 4 | 8-M24 | 44 | |

| FCL315 | 1568 | 2050 | 315 | 160 | 41 | 112 | 4 | 10-M24 | 57.7 | |

| FCL355 | 2450 | 1800 | 355 | 180 | 60 | 125 | 5 | 8-M30 | 89.5 | |

| FCL400 | 3920 | 1600 | 400 | 200 | 60 | 125 | 5 | 10-M30 | 113 | |

| FCL450 | 6174 | 1400 | 450 | 224 | 65 | 140 | 5 | 12-M30 | 145 | |

| FCL560 | 9800 | 1150 | 560 | 250 | 85 | 160 | 5 | 14-M30 | 229 | |

| FCL630 | 15680 | 1000 | 630 | 280 | 95 | 180 | 5 | 18-M30 | 296 | |

What Is a Coupling?

A coupling is a device that connects two shafts together. It transmits power from one to the other and is used to join rotating equipment. It can also allow for some degree of misalignment and end movement. It is used in mechanical engineering and manufacturing. To learn more about couplings, read this article. Mechanical connection between two objectsThe present invention relates to a method and assembly for forming a mechanical connection between two objects. The methods of this invention are suitable for connecting both solid and hollow objects. For example, the method can be used to make mechanical connections between two cylinders. This method is particularly useful for connecting two cylinders that are positioned near each other.

Mechanical connection between two objectsThe present invention relates to a method and assembly for forming a mechanical connection between two objects. The methods of this invention are suitable for connecting both solid and hollow objects. For example, the method can be used to make mechanical connections between two cylinders. This method is particularly useful for connecting two cylinders that are positioned near each other.

Absorbs vibration

A coupling insert is a part of a vehicle’s drivetrain that absorbs vibrations. These inserts are designed to prevent couplings from moving out of phase. However, the coupling inserts themselves can wear out and need to be replaced. Universal joints are an alternative if the coupling is out of phase by more than one degree. In addition, internal bearings in the coupling need to be lubricated and replaced when they begin to show signs of wear.

Another embodiment of the invention includes a flexible coupling 25 that includes rearwardly-extending lugs that extend toward the coupling member 23. These lugs interdigitate with corresponding lugs on the coupling member 23. They are spaced circumferentially. A first elastic member 28 is interposed between lugs 26 and 27, and is adapted to yield in a counterclockwise direction. As a result, it absorbs torsional vibrations.

Blocks heat transfer

Thermal coupling occurs when a solid block is thermally coupled to the air or fluid passing through it. The amount of heat transferred through a solid block depends on the heat transfer coefficients of the materials. This paper presents a numerical model to understand how heat transfers through different block materials. This work also describes the thermal resistance network for a one-dimensional block.

In some cases, thermal coupling increases the heat transfer mechanism. As illustrated in FIG. 1D, a heatpipe coupler 112 couples two heatpipes 110-1 and 110-2. This configuration allows the pipes to be coupled to the heat source and to the condenser. In addition, the heat pipe couplers may have bellows at the ends to help facilitate linear motion.

Thermal coupling is achieved by ensuring that at least one block is made of a material with a lower thermal expansion coefficient than the annulus. Ideally, the block’s mean thermal expansion coefficient is at least twenty percent lower than the annulus’s mean thermal expansion coefficient. This ensures that the thermal coupling between the two parts is as efficient as possible.

Another type of thermal coupling is achieved by using flexible elements. These are often washers or springs. These components allow the blocks to maintain physical contact with the post 55, which means that the heat transfer is more efficient even at higher temperatures. The flexibility of these elements also makes it possible to choose an element that will not impede assembly.

Protects rotating equipment

A reliable, long-lasting coupling system can reduce the risk of damage to rotating equipment. Designed to protect against torque overload and wear, Voith torque-limiting couplings provide outstanding safety and reliability. As a result, they can deliver maximum performance and minimize equipment downtime. In addition to their long-term benefits, these solutions are ideal for applications where safety and reliability are of paramount importance.

A good coupling provides many advantages, including the ability to transmit power, compensate for axial movement, and absorb shock. It is essential to choose the proper coupling for your application based on the basic conditions of your rotating equipment. For example, if you have two shafts with parallel rotation axes, you should choose a parallel coupling. Otherwise, you should use an angular coupling.

Torque-limiting couplings can also provide protection for rotating equipment by disengaging at a specific torque level. This protects the drive shaft from undergoing catastrophic failure. Torque limiters are particularly helpful for high-value equipment. By preventing catastrophic failure, you can avoid expensive repairs and minimize equipment downtime.

Coupling guards are easy to install and provide effective protection for rotating equipment. These covers are made of sheet metal bent to fit over the shaft. They are durable and easy to remove when necessary. This type of guard can prevent employees from catching their hands, tools, or loose clothing on motor coupling components.

editor by czh 2023-01-28