Product Description

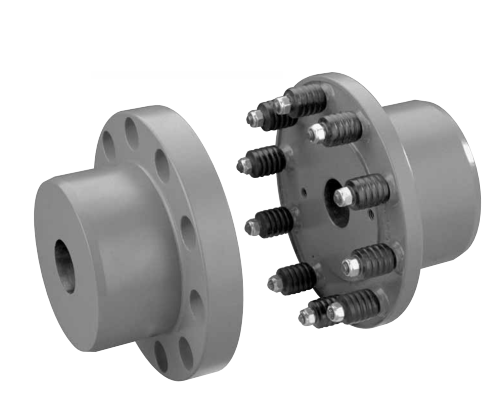

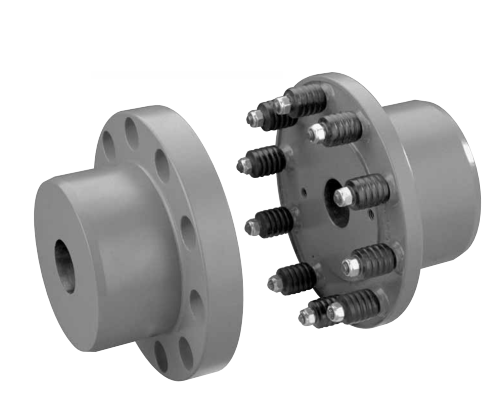

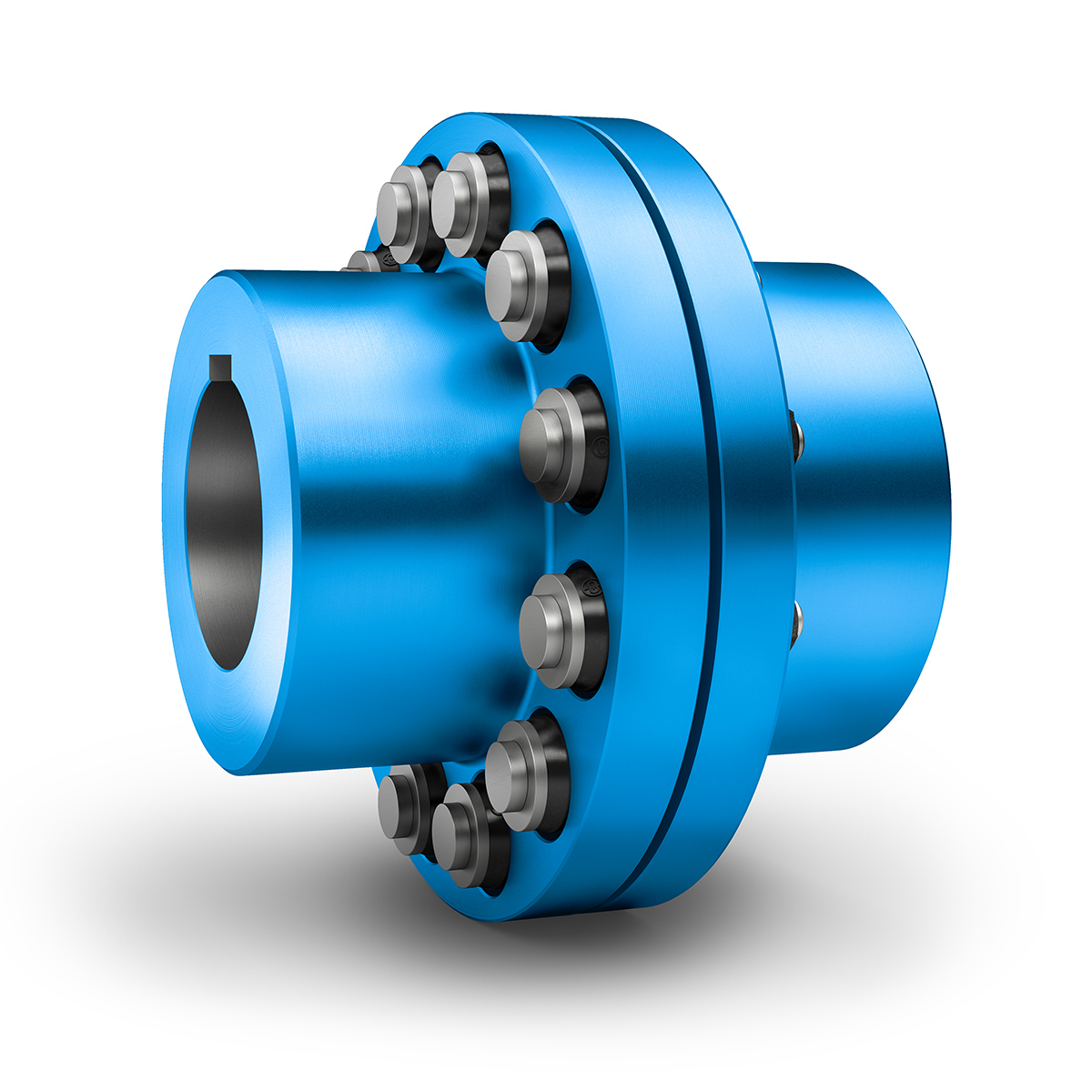

High Quality LTZ Flexible Sleeve Pin Coupling With Brake Wheel

Description:

Structural Performance:

Brake wheel and half coupling form integral structure.The brake wheel half coupling is made of cast or forged steel, and the outer surface isquenched.

Type and size of axle hole and key way: marking method is the same as LT type.Mark Description: For Z-type and j-type axle hole with countersunk hole, it refers tothe matching length of axle hole (excluding countersunk hole), which is the size L inthe picture.

Examples of tags:

LTZ10 Elastic Pin&Bush Coupling with Brake wheelActive end: J; shaft hole, A key way, d =85mm, L =100mmDriven end: J; shaft hole, B key way, d =85mm, L=100mmLT210 coupling J85x100 GB/T4323-2002.

Product paramters:

N.m= Norminal Torque; rpm= Allowable speed of rotation; d1.d2.d3= Diameter of shaft hole; Y J J1 Z= Length of shaft hole;

Allowable compensation amount(radial, angular); kg.m²= Rotational inertia; kg= Mass

1. Short-term overload shall not exceed 2 times of norminal torque value.

2. In the table,the rotational inertia and mass of the coupling are approximate values.

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Customization: |

Available

| Customized Request |

|---|

Can Pin Couplings Accommodate High Torque and High-Speed Applications?

Pin couplings are versatile and robust, making them suitable for a wide range of applications, including those involving high torque and high-speed requirements. However, the specific design and construction of the pin coupling will determine its capacity to handle such demanding conditions.

The ability of a pin coupling to accommodate high torque depends on factors such as the material used, the size and number of pins, and the overall design. High-quality pin couplings are often made from strong and durable materials like alloy steel, which allows them to withstand significant torque loads without failure or deformation.

Similarly, the capability of a pin coupling to handle high speeds depends on factors such as the balance of the coupling and the precise manufacturing of the pins and hubs. Properly balanced pin couplings can operate at higher speeds without generating excessive vibration or causing premature wear.

When selecting a pin coupling for high torque and high-speed applications, it is essential to consider the following:

- Design and Construction: Opt for pin couplings with a robust and well-engineered design to handle the expected torque and speed requirements.

- Material: Choose pin couplings made from high-quality materials known for their strength and fatigue resistance.

- Size: Select an appropriate size of pin coupling that can accommodate the torque and speed expected in the application.

- Manufacturer’s Ratings: Refer to the manufacturer’s specifications and torque-speed curves to ensure the coupling meets the desired performance criteria.

By carefully considering these factors and choosing a pin coupling designed for high torque and high-speed applications, you can ensure reliable and efficient power transmission in demanding industrial settings.

What Industries Commonly Use Pin Couplings for Power Transmission?

Pin couplings are widely used in various industries for power transmission due to their ability to accommodate misalignment and provide reliable torque transmission. Some of the industries where pin couplings are commonly employed include:

- 1. Manufacturing: In manufacturing processes, pin couplings are used in conveyor systems, mixers, agitators, and other machinery to transfer power between motors and driven equipment.

- 2. Pulp and Paper: The pulp and paper industry uses pin couplings in machinery such as pumps, fans, and rotary kilns for continuous power transmission.

- 3. Chemical and Petrochemical: Pin couplings find applications in chemical processing plants, refineries, and petrochemical facilities for various rotating equipment.

- 4. Water and Wastewater: Pin couplings are used in water treatment facilities, pumps, and blowers to transfer power efficiently.

- 5. Steel and Metal Processing: Steel mills and metal processing plants utilize pin couplings in rolling mills, extruders, and other equipment.

- 6. Food and Beverage: Pin couplings are employed in food processing machinery, packaging equipment, and conveyor systems.

- 7. Mining and Quarrying: The mining industry uses pin couplings in crushers, conveyor belts, and various mineral processing equipment.

- 8. Oil and Gas: Pin couplings are used in the oil and gas sector for pumps, compressors, and drilling equipment.

- 9. Power Generation: In power plants, pin couplings are used in turbines, generators, and other power transmission systems.

- 10. Construction and Heavy Equipment: Pin couplings find applications in construction machinery, earthmoving equipment, and other heavy-duty machinery.

- 11. Agriculture: In agricultural machinery, pin couplings are used in tractors, irrigation systems, and grain processing equipment.

These are just some examples of the industries where pin couplings are commonly used. Pin couplings offer versatility, ease of installation, and reliability, making them suitable for a wide range of applications in different sectors where power transmission is essential.

Advantages of Using Pin Couplings in Mechanical Systems

Pin couplings, also known as shear pin couplings, offer several advantages when used in mechanical systems. These advantages make them a popular choice for various industrial applications:

- 1. Overload Protection: Pin couplings are designed to provide overload protection to connected equipment. In case of excessive torque or sudden shock loads, the sacrificial pins will shear off, preventing damage to the shafts and other components.

- 2. Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts. This helps to compensate for minor misalignments and reduces the stress on the connected equipment.

- 3. Cost-Effective: The shear pins used in pin couplings are relatively inexpensive compared to other coupling components. In the event of a failure, replacing the damaged pins is a cost-effective solution, avoiding more significant repairs to the main equipment.

- 4. Easy Replacement: After shearing, the damaged pins can be quickly and easily replaced. This leads to reduced downtime and lower maintenance costs in the long run.

- 5. Versatility: Pin couplings are suitable for a wide range of applications, including pumps, compressors, fans, and other industrial machinery. Their ability to handle varying operating conditions makes them versatile in different environments.

- 6. Shock Load Absorption: Pin couplings can absorb and dissipate shock loads effectively. The shear pins act as a buffer, protecting the equipment from sudden impacts or overloads.

Despite their numerous advantages, it is essential to consider the limitations of pin couplings as well. They have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings. Additionally, the need to replace shear pins after each failure may lead to more frequent maintenance requirements in applications with frequent overloads or misalignments.

In conclusion, pin couplings provide reliable torque transmission and safety features, making them a valuable component in various mechanical systems. Their ability to protect against overloads and accommodate misalignments makes them a practical choice in a wide range of industrial applications.

editor by CX 2024-05-17

China best Galvanized Frame Scaffolding Joint Pin Coupling Pin for Walk Through Frames

Product Description

Product Description

Frame scaffolding is also called tubular steel frame scaffolding, door style frame scaffolding, is a long established modular frame scaffolding system serving as working platform for construction and decoration purposes, which is composed of main frames, catwalk or walk board, braces or cross braces, brackets, coupling pins of spigot, guardrails and sometimes casters, etc.

| Pic. | Item | A (Width) | B (Height) | |

| Main Frame

Outer tube: 42*2.2mm/2.0mm/1.8mm Inner tube: 25*1.5mm/1.8mm/2.0mm |

1219mm | 914mm | ||

| 1219mm | 1219mm | |||

| 1219mm | 1524mm | |||

| 1219mm | 1700mm | |||

| 1219mm | 1930mm | |||

| 914mm | 1219mm | |||

| 914mm | 1524mm | |||

| 914mm | 1700mm | |||

| 914mm | 1930mm | |||

| H Frame

Outer tube: 42*2.2mm/2.0mm/1.8mm Inner tube: 25*1.5mm/1.8mm/2.0mm |

1219mm | 914mm | ||

| 1219mm | 1219mm | |||

| 1219mm | 1524mm | |||

| 1219mm | 1700mm | |||

| 1219mm | 1930mm | |||

| 914mm | 914mm | |||

| 914mm | 1219mm | |||

| 914mm | 1524mm | |||

| 914mm | 1700mm | |||

| 914mm | 1930mm | |||

| Item | A (width) | B (height) | C (length) | |

| 1829mm | 1219mm | 2198mm | ||

| 1219mm | 1219mm | 1724mm | ||

| 1829mm | 914mm | 2045mm | ||

| 1829mm | 610mm | 1928mm | ||

| 1219mm | 610mm | 1363mm | ||

| Item | Size | |||

| Joint Pin | 36*1.5*225mm | |||

| 36*1.2*225mm | ||||

| 36*1.0*225mm | ||||

Packaging & Shipping

Application

Company Profile

HangZhou CHINAMFG Industry Co., Ltd, with an investment of U.S. Dollars of 8 million, is a professional manufacturer engaged in the design, production & sale of scaffolding systems.

1. Location: HangZhou CHINAMFG is leading scaffolding manufacturer, located in HangZhou, ZheJiang Province, the raw material basement.

2. Team: We have professional team for sale, project design and construction.

3. Main products: Ringlock Scaffolding, Frame Scaffolding, Steel Plank, Catwalk, Ladders, Pipe & Clamp, Steel Prop, etc.

4. Production capacity: 7000-10000 Tons/month.

5. Loading capacity: 8-12 containers/day.

6. Delivery time: 10-15 days for 3-5 containers.

Fast delivery to satisfy your urgent project demand.

FAQ

Q1: Are you a factory or trading company?

A: We are a factory specializing in manufacturing scaffolding material.

Q2: Where is the loading port?

A: ZheJiang (Xihu (West Lake) Dis.g) Port.

Q3: What’s the MOQ of the product?

A: Different item has different MOQ. Normally one Container is preferred.

Q4: What certificates do you have?

A: We have ISO 9001, SGS certification.

Q5: Can I get some samples?

A: Yes, but usually the customer will pay for the cost and freight charges.

Q6: Do you have an OEM service?

A: Yes. We can provide OEM and ODM services as your requirements.

Q7: How long is the production cycle after ordering?

A: General it is about 15-30 days, according to different quantity requirement.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Structural Style: | Multi-Pole Scaffolding |

| Framework: | Combined Scaffolding |

| Supporting Mode: | Projecting Scaffolding |

| Lapping Form: | Full Scaffolding |

| Scaffolding Part Type: | Scaffolding Frames |

| Customization: |

Available

| Customized Request |

|---|

How Do Pin Couplings Compare to Other Types of Couplings in Terms of Performance?

Pin couplings offer certain advantages and disadvantages compared to other types of couplings, and their performance characteristics can vary depending on the specific application requirements. Below is a comparison of pin couplings with some commonly used couplings:

1. Gear Couplings:

- Flexibility: Gear couplings are more rigid than pin couplings and may not offer the same level of misalignment capacity.

- Torsional Stiffness: Gear couplings provide higher torsional stiffness, making them suitable for applications requiring precise torque transmission.

- Shock Absorption: Gear couplings can handle higher shock loads due to their robust design and greater stiffness.

- Maintenance: Gear couplings may require periodic lubrication and maintenance compared to maintenance-free pin couplings.

- Applications: Gear couplings are commonly used in heavy-duty and high-torque applications where precise torque transmission is essential.

2. Flexible (Elastomeric) Couplings:

- Flexibility: Elastomeric couplings offer higher misalignment capacity than pin couplings and can handle angular, parallel, and axial misalignment.

- Shock Absorption: Elastomeric couplings provide excellent shock absorption, damping vibrations, and protecting connected equipment.

- Torsional Stiffness: Elastomeric couplings have lower torsional stiffness compared to pin couplings, making them more forgiving in high shock load applications.

- Installation: Elastomeric couplings are easy to install and require no lubrication, making them maintenance-free.

- Applications: Elastomeric couplings are commonly used in pumps, compressors, and other machinery where vibration isolation is crucial.

3. Rigid Couplings:

- Torsional Stiffness: Rigid couplings provide high torsional stiffness, ensuring accurate torque transmission.

- Misalignment Capacity: Rigid couplings have little to no misalignment capacity and require precise shaft alignment.

- Applications: Rigid couplings are used in applications where precise alignment is essential, such as shaft-to-shaft connections in high-precision systems.

Conclusion:

Pin couplings strike a balance between flexibility and torsional stiffness, making them suitable for applications with moderate misalignment and shock loads. They are often used in general industrial applications, conveyors, and light to medium-duty machinery.

When selecting a coupling for a specific application, it is crucial to consider factors such as misalignment requirements, shock and vibration loads, torsional stiffness, maintenance needs, and the level of precision required. Each coupling type has its strengths and weaknesses, and the appropriate choice will depend on the specific demands of the application.

Can Pin Couplings Be Used for Both Motor-to-Shaft and Shaft-to-Shaft Connections?

Yes, pin couplings can be used for both motor-to-shaft and shaft-to-shaft connections in various mechanical systems. The versatile design of pin couplings allows them to connect two shafts with aligned or misaligned centers, making them suitable for a wide range of applications.

Motor-to-Shaft Connections: In motor-driven systems, pin couplings are commonly used to connect the motor shaft to the driven shaft of the equipment. The motor can be an electric motor, combustion engine, or any other type of power source. The pin coupling efficiently transfers torque from the motor shaft to the equipment’s driven shaft, enabling power transmission and mechanical motion.

Shaft-to-Shaft Connections: Pin couplings are also well-suited for shaft-to-shaft connections, where two separate shafts need to be joined together. This could be the case when extending the length of a shaft or connecting two separate pieces of rotating equipment. The pin coupling provides a secure and flexible connection between the two shafts, allowing torque to be transmitted between them while accommodating misalignment.

It is essential to consider the specific requirements of the application when selecting a pin coupling. Factors such as the amount of misalignment, torque capacity, operating conditions, and space constraints should be taken into account to ensure the coupling can effectively and reliably connect the motor and shafts.

Overall, the versatility and performance of pin couplings make them a popular choice for both motor-to-shaft and shaft-to-shaft connections in various industrial and mechanical systems.

Understanding Pin Couplings and Their Functionality

A pin coupling, also known as a shear pin coupling, is a type of mechanical coupling used to connect two rotating shafts in a mechanical system. It is designed to transmit torque while allowing for a limited amount of angular misalignment between the shafts. The primary function of a pin coupling is to protect the connected equipment from torque overload and prevent damage to the shafts and other components in case of sudden shock or overload.

How a Pin Coupling Works:

A typical pin coupling consists of two hubs, one on each shaft to be connected, and a series of pins that pass through the hubs to join them together. The pins are usually made of a softer material than the hubs, such as brass or aluminum, to act as sacrificial elements. The number and size of the pins depend on the coupling’s torque rating and the required angular misalignment capacity.

When the shafts are misaligned, the pins experience shear stress as they bend under the applied load. In normal operating conditions, the pins remain intact and allow the torque to transfer from one shaft to another. However, in the event of an overload or excessive misalignment, the pins will shear off, preventing the transmission of excessive torque and protecting the connected equipment from damage.

After shearing, the damaged pins can be easily replaced, and the coupling can be put back into service without major repairs to the equipment. This feature makes pin couplings particularly suitable for applications with varying operating conditions and environments where shock loads or sudden overloads may occur.

Advantages of Pin Couplings:

– Protection against Overload: The shear pins act as a safety feature, protecting the connected equipment from excessive torque and sudden shocks.

– Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts.

– Easy Replacement: After shearing, the damaged pins can be quickly replaced, reducing downtime and maintenance costs.

– Versatility: Suitable for a wide range of applications, including pumps, compressors, and other industrial machinery.

– Cost-Effective: The sacrificial pins are cost-effective components that can be easily replaced, avoiding costly repairs to the main equipment.

Limitations:

– Pin couplings have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings.

– The need to replace the shear pins after each failure may lead to frequent maintenance requirements in applications with frequent overloads or misalignments.

In summary, pin couplings offer a reliable and cost-effective solution for torque transmission and protection against overloads in various mechanical systems. Their ability to accommodate misalignment and absorb shock loads makes them suitable for a wide range of industrial applications.

editor by CX 2024-05-16

China OEM Excavator Coupling Assy Portabl Track Pin Press Rubber Black Coupling 2km00001-up

Product Description

Excavator Coupling Assy Portabl Track Pin Press Rubber Black Coupling 2KM00001-UP

Basic information:

| Part Name | Hydraulic Pump Coupling |

| Machine model | 2KM00001-UP |

| Application | Excavator |

| Material | Rubber,Iron |

| Color | Black |

| Category | Construction machinery parts |

| Packing | Neutral Package |

| Country of Origin | China |

| Lead time | In Stock |

| Condition | New&OEM Part |

| MOQ | No limited |

| Processing | Forging |

| Warranty | Supply 3 months warranty for the products from the date of arrival |

| Our Services: | One-stop purchase |

About us:

specialized in:

couplings, rubber mounts, gera parts, hydraulic seals and seal kits for hydraulic hammers, rock breakers, hydraulic excavators,wheel loaders, and JCB badkhoe loaders.

And, Our company also supply:

Engine parts, hydraulic piston pump and hydraulic travel motor, Swing motor assembly and hydraulic component parts, electric parts, etc. Hydraulic hammer breaker parts with piston, cylinder, chisel, through bolt, side bolt, top bush, front head bushing,accumlator, valve, etc.

We always try our best for all our customers and make it better and better. Welcome!

Products Show:

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Support |

|---|---|

| Warranty: | Six Months |

| Type: | Coupling |

| Application: | Excavator |

| Certification: | CE |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

Can Pin Couplings Accommodate High Torque and High-Speed Applications?

Pin couplings are versatile and robust, making them suitable for a wide range of applications, including those involving high torque and high-speed requirements. However, the specific design and construction of the pin coupling will determine its capacity to handle such demanding conditions.

The ability of a pin coupling to accommodate high torque depends on factors such as the material used, the size and number of pins, and the overall design. High-quality pin couplings are often made from strong and durable materials like alloy steel, which allows them to withstand significant torque loads without failure or deformation.

Similarly, the capability of a pin coupling to handle high speeds depends on factors such as the balance of the coupling and the precise manufacturing of the pins and hubs. Properly balanced pin couplings can operate at higher speeds without generating excessive vibration or causing premature wear.

When selecting a pin coupling for high torque and high-speed applications, it is essential to consider the following:

- Design and Construction: Opt for pin couplings with a robust and well-engineered design to handle the expected torque and speed requirements.

- Material: Choose pin couplings made from high-quality materials known for their strength and fatigue resistance.

- Size: Select an appropriate size of pin coupling that can accommodate the torque and speed expected in the application.

- Manufacturer’s Ratings: Refer to the manufacturer’s specifications and torque-speed curves to ensure the coupling meets the desired performance criteria.

By carefully considering these factors and choosing a pin coupling designed for high torque and high-speed applications, you can ensure reliable and efficient power transmission in demanding industrial settings.

Role of Pin Coupling in Reducing Downtime and Maintenance Costs

A pin coupling plays a crucial role in reducing downtime and maintenance costs in various mechanical systems and power transmission applications. Its design and features contribute to improved reliability and ease of maintenance, resulting in enhanced operational efficiency and cost savings. Here’s how pin couplings achieve these benefits:

1. Shock Absorption: Pin couplings are known for their ability to absorb and dampen shocks and vibrations generated during operation. By cushioning the impact of sudden loads or torque spikes, they protect the connected equipment from potential damage, reducing the frequency of unexpected breakdowns and downtime.

2. Misalignment Tolerance: Pin couplings can tolerate a certain degree of misalignment between shafts, such as angular and parallel misalignment. This flexibility allows for easier installation and alignment of equipment, saving time and effort during setup and reducing the need for precise alignment procedures.

3. Low Maintenance: Pin couplings are designed with simplicity in mind, often consisting of only two coupling halves connected by pins. This straightforward construction means fewer components that can wear out or require regular maintenance. Additionally, the flexibility of the pins helps reduce wear on the coupling and connected equipment, leading to longer maintenance intervals.

4. Easy Replacement: In the event of a failure or wear, pin couplings are relatively easy to replace compared to some other coupling types. The simplicity of their design allows for quick disassembly and reassembly, minimizing downtime during maintenance or replacement procedures.

5. Cost-Effective: The combination of low maintenance requirements and reduced downtime translates into cost savings for businesses. With fewer unexpected breakdowns and lower maintenance expenses, the overall cost of ownership for systems employing pin couplings can be more economical.

6. Reliability: Pin couplings are known for their reliability and durability. When properly selected and installed, they can provide long service life without frequent replacements, contributing to stable and consistent system performance.

By minimizing downtime, maintenance efforts, and associated costs, pin couplings are a preferred choice in various industrial applications. However, it is crucial to ensure that the pin coupling is correctly sized and installed, and regular inspections and maintenance are conducted to maximize its benefits and prevent premature failure.

Selecting the Appropriate Pin Coupling for a Specific Application

Choosing the right pin coupling for a specific application involves considering several factors to ensure optimal performance, reliability, and safety. Here are the key steps to select the appropriate pin coupling:

- 1. Determine the Application Requirements: Understand the specific requirements of the application, including torque and speed specifications, shaft sizes, and misalignment tolerances. Consider the operating conditions, such as temperature, humidity, and exposure to corrosive substances.

- 2. Calculate Torque and Power: Calculate the torque and power requirements of the application to determine the appropriate pin coupling’s torque capacity. Make sure to consider both steady-state and peak torque loads.

- 3. Consider Misalignment Tolerance: Evaluate the degree of misalignment expected in the system. Different pin coupling designs offer varying levels of misalignment tolerance. Choose a coupling that can accommodate the expected misalignment without compromising performance.

- 4. Select the Pin Coupling Type: Based on the application requirements, choose the appropriate pin coupling type – single pin, double pin, triangular pin, splined pin, or taper pin coupling. Each type offers different torque capacities and misalignment capabilities.

- 5. Check Material and Construction: Consider the materials used in the pin coupling’s construction. Common materials include steel, stainless steel, and alloy materials. The material should be suitable for the application’s environmental conditions and corrosion resistance.

- 6. Verify Safety Features: Ensure the selected pin coupling has safety features, such as a fail-safe mechanism to protect equipment from overload or shock loads. Safety is crucial to prevent damage to machinery and ensure operator protection.

- 7. Consult with Manufacturers or Engineers: If unsure about the best pin coupling for the application, consult with coupling manufacturers or mechanical engineers. They can provide valuable insights and recommendations based on their expertise.

By following these steps, you can select the appropriate pin coupling that matches the specific needs of the application, providing reliable and efficient power transmission while minimizing the risk of downtime and equipment failure.

editor by CX 2024-05-16

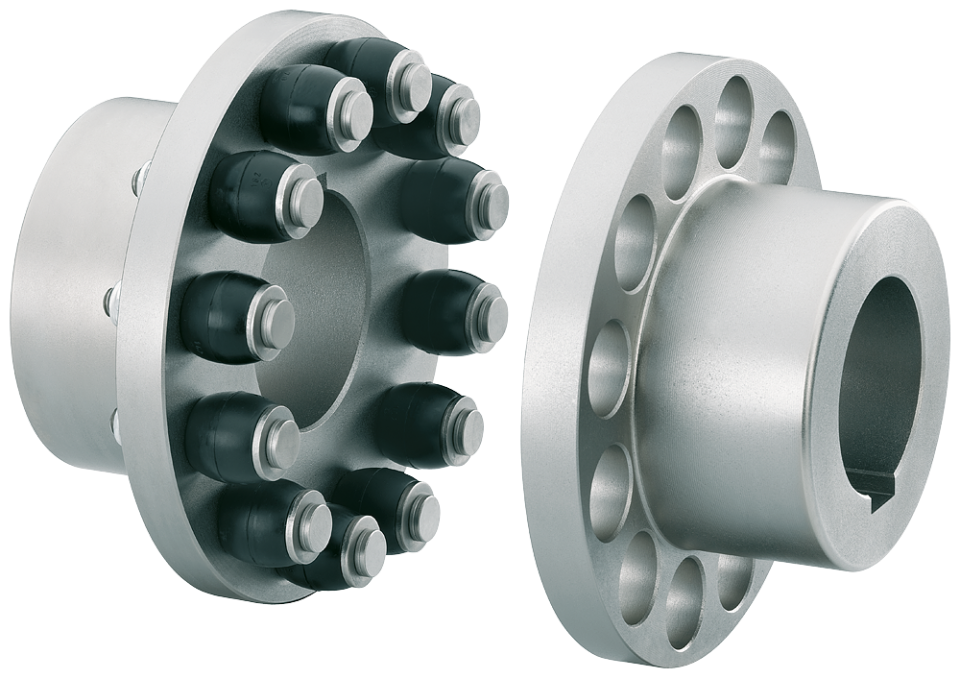

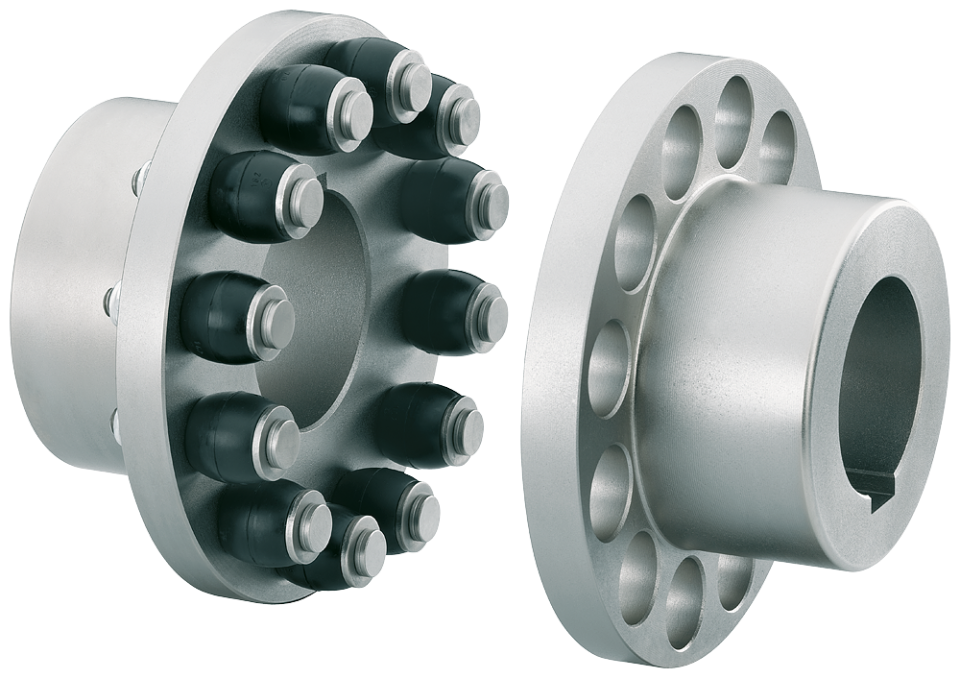

China Good quality Flexible Shaft Sleeve Flexible FCL Pin Coupling

Product Description

Flexible Shaft Sleeve Flexible FCL Pin Coupling

The characteristics of FCL Flexible Pin & Bush Coupling

(1)Coupling is simple in structure, convenient installation, easy replacement, small size, light weight.

(2)If the installation adjustment can keep 2 relative displacement within the prescribed limits, then coupling will have satisfactory performance and long service life.

(3) It can be widely applied to all kinds of medium and small power transmission shafts, such as reducer, crane, compressor, conveyor, textile machine, hoist and ball mill, which are not loaded by motors.

(4)The allowable relative displacement of the elastic sleeve pin couplings:

Radial displacement: 0.2~0.6mm angular displacement: 0 ° 30 ‘~1° 30’

Related products:

Production workshop:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What Are the Maintenance Requirements for Pin Couplings?

Pin couplings are known for their simplicity and ease of maintenance. Regular maintenance helps ensure the longevity and optimal performance of pin couplings in various mechanical systems. Here are the key maintenance requirements for pin couplings:

- Lubrication: Most pin couplings require periodic lubrication to reduce friction between the pins and the coupling hubs. Lubrication helps prevent wear and corrosion, ensuring smooth operation.

- Inspection: Regular visual inspections are essential to identify any signs of wear, misalignment, or damage. Inspecting the pins, coupling hubs, and surrounding components can help detect potential issues early on.

- Torque Check: It is crucial to periodically check and retighten the bolts or screws that secure the coupling to the shafts. Loose fasteners can lead to misalignment and coupling failure.

- Alignment: Proper shaft alignment is critical for the effective functioning of pin couplings. Regularly check and adjust the alignment if necessary to minimize wear and vibrations.

- Environmental Protection: In harsh environments or corrosive conditions, take measures to protect the pin coupling from contaminants or chemicals that could cause damage.

- Replacement of Worn Components: When any of the coupling components, such as pins or hubs, show signs of significant wear, they should be replaced promptly to prevent further damage.

It is important to follow the manufacturer’s maintenance guidelines and recommendations for the specific type of pin coupling used in the application. Regular maintenance not only ensures the smooth operation of the coupling but also helps prevent unexpected breakdowns and reduces the risk of costly downtime. Proper maintenance can extend the service life of pin couplings and contribute to the overall reliability of the connected equipment.

What Industries Commonly Use Pin Couplings for Power Transmission?

Pin couplings are widely used in various industries for power transmission due to their ability to accommodate misalignment and provide reliable torque transmission. Some of the industries where pin couplings are commonly employed include:

- 1. Manufacturing: In manufacturing processes, pin couplings are used in conveyor systems, mixers, agitators, and other machinery to transfer power between motors and driven equipment.

- 2. Pulp and Paper: The pulp and paper industry uses pin couplings in machinery such as pumps, fans, and rotary kilns for continuous power transmission.

- 3. Chemical and Petrochemical: Pin couplings find applications in chemical processing plants, refineries, and petrochemical facilities for various rotating equipment.

- 4. Water and Wastewater: Pin couplings are used in water treatment facilities, pumps, and blowers to transfer power efficiently.

- 5. Steel and Metal Processing: Steel mills and metal processing plants utilize pin couplings in rolling mills, extruders, and other equipment.

- 6. Food and Beverage: Pin couplings are employed in food processing machinery, packaging equipment, and conveyor systems.

- 7. Mining and Quarrying: The mining industry uses pin couplings in crushers, conveyor belts, and various mineral processing equipment.

- 8. Oil and Gas: Pin couplings are used in the oil and gas sector for pumps, compressors, and drilling equipment.

- 9. Power Generation: In power plants, pin couplings are used in turbines, generators, and other power transmission systems.

- 10. Construction and Heavy Equipment: Pin couplings find applications in construction machinery, earthmoving equipment, and other heavy-duty machinery.

- 11. Agriculture: In agricultural machinery, pin couplings are used in tractors, irrigation systems, and grain processing equipment.

These are just some examples of the industries where pin couplings are commonly used. Pin couplings offer versatility, ease of installation, and reliability, making them suitable for a wide range of applications in different sectors where power transmission is essential.

Advantages of Using Pin Couplings in Mechanical Systems

Pin couplings, also known as shear pin couplings, offer several advantages when used in mechanical systems. These advantages make them a popular choice for various industrial applications:

- 1. Overload Protection: Pin couplings are designed to provide overload protection to connected equipment. In case of excessive torque or sudden shock loads, the sacrificial pins will shear off, preventing damage to the shafts and other components.

- 2. Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts. This helps to compensate for minor misalignments and reduces the stress on the connected equipment.

- 3. Cost-Effective: The shear pins used in pin couplings are relatively inexpensive compared to other coupling components. In the event of a failure, replacing the damaged pins is a cost-effective solution, avoiding more significant repairs to the main equipment.

- 4. Easy Replacement: After shearing, the damaged pins can be quickly and easily replaced. This leads to reduced downtime and lower maintenance costs in the long run.

- 5. Versatility: Pin couplings are suitable for a wide range of applications, including pumps, compressors, fans, and other industrial machinery. Their ability to handle varying operating conditions makes them versatile in different environments.

- 6. Shock Load Absorption: Pin couplings can absorb and dissipate shock loads effectively. The shear pins act as a buffer, protecting the equipment from sudden impacts or overloads.

Despite their numerous advantages, it is essential to consider the limitations of pin couplings as well. They have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings. Additionally, the need to replace shear pins after each failure may lead to more frequent maintenance requirements in applications with frequent overloads or misalignments.

In conclusion, pin couplings provide reliable torque transmission and safety features, making them a valuable component in various mechanical systems. Their ability to protect against overloads and accommodate misalignments makes them a practical choice in a wide range of industrial applications.

editor by CX 2024-05-16

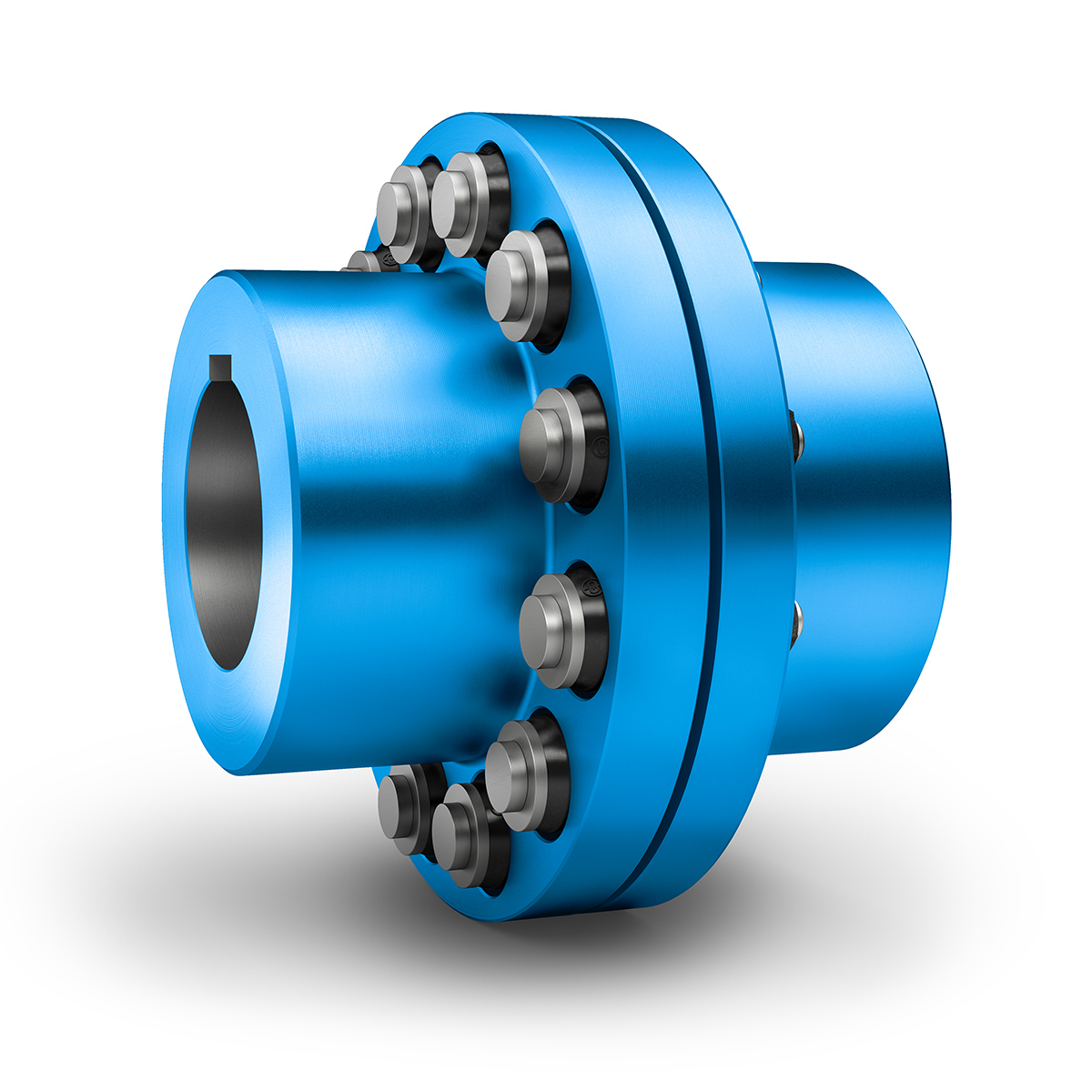

China Hot selling High Quality Flexible Pin Coupling FCL

Product Description

Flexible Pin Coupling FCL, FCL flexible coupling is widely used for its compact design, easy installation, convenient maintenance, small size and light weight. As long as the relative displacement between shafts are kept within the specified tolerance, couplings will operate the best function and have a longer working life. Thus, it is greatly demanded in medium and miner power transmission system driven by motor, such as speed reducer, hoist, compress, conveyor, spinning and weaving and ball mill.

Our FCL Couplings(Flexible Pin Couplings) are Standard, but also customized.

The material for the FCL Coupling(Flexible Pin Coupling) is normally C45 Steel, Alloy steel, also cast iron etc.

The surface treatment should be black oxide/black finished, phosphate, powder coated etc.

Our FCL Couplings(Flexible Pin Couplings) have been mainly exported to Southeast Asia market, Europe and south American etc.

We can also supply chain coupling, roller chain coupling, rigid couplings, flexible couplings, fcl coupling, flexible rubber fcl coupling, fcl flexible coupling, forged steel fcl coupling, flexible coupling fcl, fcl flexible shaft coupling, jaw coupling, hrc coupling, CHINAMFG coupling, cast steel coupling, aluminum coupling, stainless steel coupling, pin coupling, mh coupling, nm coupling, spacer coupling, taper lock rigid coupling, flange coupling, sleeve coupling, nylon sleeve gear coupling, gear coupling, crc coupling, js coupling

Competitive Advantage:

More than 20 years advanced technology and experience of us will give strong support for the coupling you need. We will understand your need of product quickly, and give quick respond and good service. A lot of cases of our products will show you that it worth your trust.

Under the full quality control system, our products go through the precise product line and strict testing process. We have excellent working flow and standard to ensure stability, products reliable enough for using.

Take our scale economy, raw material superiority, and CHINAMFG for clients to account, our price do have a great competitiveness. They are good value and cost effective than your imagine.

We sincerely hope establishing long and friendly business relations with clients from all over the world. Our goal is not just providing product, but also providing a complete solution including product design, tooling, fabrication and service for our customers to achieve their upmost satisfaction.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Low Carbon Steel |

|---|---|

| Surface Finishing: | Zinc Plated |

| Certification: | ISO |

| Customized: | Non-Customized |

| Connection: | Flange |

| Surface Treatment: | Without Treatment |

| Customization: |

Available

| Customized Request |

|---|

Are There Any Safety Considerations When Using Pin Couplings in Rotating Machinery?

Yes, there are several safety considerations to keep in mind when using pin couplings in rotating machinery. These considerations are essential to ensure the safe and efficient operation of the equipment and to protect personnel working in the vicinity. Here are some key safety points to consider:

- Guarding: When installing pin couplings, it is crucial to provide adequate guarding around the coupling area. This helps prevent accidental contact with the rotating coupling components, such as pins and hubs, which could cause severe injuries.

- Maintenance and Inspection: Regular maintenance and inspection of the pin coupling are vital to identify any signs of wear, misalignment, or damage. Any worn or damaged components should be replaced immediately to prevent coupling failure, which could lead to sudden equipment shutdown or safety hazards.

- Proper Alignment: Ensuring precise alignment of the connected shafts is crucial to the safe operation of the pin coupling. Misalignment can lead to increased stresses and premature wear on the coupling components, resulting in potential failures.

- Torque and Speed Limits: Adhering to the manufacturer’s recommended torque and speed limits for the pin coupling is essential for its safe operation. Exceeding these limits can lead to overloading and failure of the coupling.

- Environmental Considerations: Take into account the operating environment when selecting a pin coupling. Extreme temperatures, corrosive atmospheres, or harsh conditions may require special materials or coatings to ensure the coupling’s integrity and prevent premature failure.

- Training and Awareness: Operators and maintenance personnel should receive proper training on the safe handling, installation, and maintenance of pin couplings. Awareness of potential hazards and safety protocols is crucial for the safe use of rotating machinery.

- Emergency Shutdown: Install emergency shutdown systems that can quickly stop the rotating machinery in case of any safety concerns or abnormal conditions.

- Compliance with Regulations: Ensure that the use of pin couplings complies with all relevant safety and industry regulations and standards.

By taking these safety considerations into account and implementing proper safety measures, the use of pin couplings in rotating machinery can be done safely and effectively, mitigating potential risks and ensuring a safe working environment for personnel.

Role of Pin Coupling in Reducing Downtime and Maintenance Costs

A pin coupling plays a crucial role in reducing downtime and maintenance costs in various mechanical systems and power transmission applications. Its design and features contribute to improved reliability and ease of maintenance, resulting in enhanced operational efficiency and cost savings. Here’s how pin couplings achieve these benefits:

1. Shock Absorption: Pin couplings are known for their ability to absorb and dampen shocks and vibrations generated during operation. By cushioning the impact of sudden loads or torque spikes, they protect the connected equipment from potential damage, reducing the frequency of unexpected breakdowns and downtime.

2. Misalignment Tolerance: Pin couplings can tolerate a certain degree of misalignment between shafts, such as angular and parallel misalignment. This flexibility allows for easier installation and alignment of equipment, saving time and effort during setup and reducing the need for precise alignment procedures.

3. Low Maintenance: Pin couplings are designed with simplicity in mind, often consisting of only two coupling halves connected by pins. This straightforward construction means fewer components that can wear out or require regular maintenance. Additionally, the flexibility of the pins helps reduce wear on the coupling and connected equipment, leading to longer maintenance intervals.

4. Easy Replacement: In the event of a failure or wear, pin couplings are relatively easy to replace compared to some other coupling types. The simplicity of their design allows for quick disassembly and reassembly, minimizing downtime during maintenance or replacement procedures.

5. Cost-Effective: The combination of low maintenance requirements and reduced downtime translates into cost savings for businesses. With fewer unexpected breakdowns and lower maintenance expenses, the overall cost of ownership for systems employing pin couplings can be more economical.

6. Reliability: Pin couplings are known for their reliability and durability. When properly selected and installed, they can provide long service life without frequent replacements, contributing to stable and consistent system performance.

By minimizing downtime, maintenance efforts, and associated costs, pin couplings are a preferred choice in various industrial applications. However, it is crucial to ensure that the pin coupling is correctly sized and installed, and regular inspections and maintenance are conducted to maximize its benefits and prevent premature failure.

Understanding Pin Couplings and Their Functionality

A pin coupling, also known as a shear pin coupling, is a type of mechanical coupling used to connect two rotating shafts in a mechanical system. It is designed to transmit torque while allowing for a limited amount of angular misalignment between the shafts. The primary function of a pin coupling is to protect the connected equipment from torque overload and prevent damage to the shafts and other components in case of sudden shock or overload.

How a Pin Coupling Works:

A typical pin coupling consists of two hubs, one on each shaft to be connected, and a series of pins that pass through the hubs to join them together. The pins are usually made of a softer material than the hubs, such as brass or aluminum, to act as sacrificial elements. The number and size of the pins depend on the coupling’s torque rating and the required angular misalignment capacity.

When the shafts are misaligned, the pins experience shear stress as they bend under the applied load. In normal operating conditions, the pins remain intact and allow the torque to transfer from one shaft to another. However, in the event of an overload or excessive misalignment, the pins will shear off, preventing the transmission of excessive torque and protecting the connected equipment from damage.

After shearing, the damaged pins can be easily replaced, and the coupling can be put back into service without major repairs to the equipment. This feature makes pin couplings particularly suitable for applications with varying operating conditions and environments where shock loads or sudden overloads may occur.

Advantages of Pin Couplings:

– Protection against Overload: The shear pins act as a safety feature, protecting the connected equipment from excessive torque and sudden shocks.

– Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts.

– Easy Replacement: After shearing, the damaged pins can be quickly replaced, reducing downtime and maintenance costs.

– Versatility: Suitable for a wide range of applications, including pumps, compressors, and other industrial machinery.

– Cost-Effective: The sacrificial pins are cost-effective components that can be easily replaced, avoiding costly repairs to the main equipment.

Limitations:

– Pin couplings have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings.

– The need to replace the shear pins after each failure may lead to frequent maintenance requirements in applications with frequent overloads or misalignments.

In summary, pin couplings offer a reliable and cost-effective solution for torque transmission and protection against overloads in various mechanical systems. Their ability to accommodate misalignment and absorb shock loads makes them suitable for a wide range of industrial applications.

editor by CX 2024-05-16

China high quality OEM 2L1w4684AA for CHINAMFG Rubber Pin Flexible Elastic Pin Bush Coupling Shaft Couplings

Product Description

Basic Info.

| Model NO. | 2L1W4684AA | Parts | Auto Parts For Center Support Bearing | |

| Specification | 6*14*120 | Trademark | YTK or Customized | |

| Price | Negotiable | Transport Packing | Neutral Packing & Customized | |

| Exportation | ZheJiang Port | Bearing Quality | ZV3 Level | |

| Warranty | One Year or Above | Laser Mark | Available | |

| Applicable Models | FORD | Production Capacity | 60, 1220843 |

BMW |

| 7L0521403 | Volkswagen Touareg | 245710115 | Mercedes-Benz | |

| 2L1W4684AA 4165078 |

FORD | 95712781 | Hyundai | |

| 12341 | Mercedes-Benz | 26117512619 | BMW | |

| 26117546425 | BMW |

-FAQ:

Q1. What is your terms of packing?

Generally, we pack our goods in neutral boxes and brown cartons or as your demand.

If you have legally registered patent,we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of delivery?

EXW, FOB, CIF, CFR

Q3. How about your delivery time?

Generally, it will take 10 to 30 days after receiving your advance payment.

The specific delivery time depends on the items and the quantity of your order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Condition: | New |

| Color: | Black |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How Do Pin Couplings Compare to Other Types of Couplings in Terms of Performance?

Pin couplings offer certain advantages and disadvantages compared to other types of couplings, and their performance characteristics can vary depending on the specific application requirements. Below is a comparison of pin couplings with some commonly used couplings:

1. Gear Couplings:

- Flexibility: Gear couplings are more rigid than pin couplings and may not offer the same level of misalignment capacity.

- Torsional Stiffness: Gear couplings provide higher torsional stiffness, making them suitable for applications requiring precise torque transmission.

- Shock Absorption: Gear couplings can handle higher shock loads due to their robust design and greater stiffness.

- Maintenance: Gear couplings may require periodic lubrication and maintenance compared to maintenance-free pin couplings.

- Applications: Gear couplings are commonly used in heavy-duty and high-torque applications where precise torque transmission is essential.

2. Flexible (Elastomeric) Couplings:

- Flexibility: Elastomeric couplings offer higher misalignment capacity than pin couplings and can handle angular, parallel, and axial misalignment.

- Shock Absorption: Elastomeric couplings provide excellent shock absorption, damping vibrations, and protecting connected equipment.

- Torsional Stiffness: Elastomeric couplings have lower torsional stiffness compared to pin couplings, making them more forgiving in high shock load applications.

- Installation: Elastomeric couplings are easy to install and require no lubrication, making them maintenance-free.

- Applications: Elastomeric couplings are commonly used in pumps, compressors, and other machinery where vibration isolation is crucial.

3. Rigid Couplings:

- Torsional Stiffness: Rigid couplings provide high torsional stiffness, ensuring accurate torque transmission.

- Misalignment Capacity: Rigid couplings have little to no misalignment capacity and require precise shaft alignment.

- Applications: Rigid couplings are used in applications where precise alignment is essential, such as shaft-to-shaft connections in high-precision systems.

Conclusion:

Pin couplings strike a balance between flexibility and torsional stiffness, making them suitable for applications with moderate misalignment and shock loads. They are often used in general industrial applications, conveyors, and light to medium-duty machinery.

When selecting a coupling for a specific application, it is crucial to consider factors such as misalignment requirements, shock and vibration loads, torsional stiffness, maintenance needs, and the level of precision required. Each coupling type has its strengths and weaknesses, and the appropriate choice will depend on the specific demands of the application.

Factors to Consider When Choosing a Pin Coupling for a Specific System

When selecting a pin coupling for a specific system, several critical factors need to be considered to ensure optimal performance, reliability, and longevity. Each application has unique requirements, and choosing the right pin coupling involves assessing the following factors:

1. Torque and Power Requirements: Determine the torque and power transmission requirements of the system. The pin coupling must be capable of handling the maximum torque and power generated by the connected equipment.

2. Operating Speed: Consider the rotational speed of the system’s driving and driven shafts. The pin coupling’s design should allow for smooth and efficient operation at the specified speed range.

3. Misalignment Tolerance: Assess the degree of misalignment between the shafts that the coupling needs to accommodate. Pin couplings are suitable for applications with moderate angular, parallel, and axial misalignment.

4. Operating Environment: Consider the environmental conditions the coupling will be exposed to, including temperature, humidity, dust, and presence of corrosive substances. Choose a pin coupling with materials and surface treatments suitable for the operating environment.

5. Size and Space Constraints: Ensure that the selected pin coupling fits within the available space and does not interfere with other components in the system.

6. Serviceability and Maintenance: Evaluate the ease of installation, maintenance, and replacement of the pin coupling. Easy-to-service couplings can help reduce downtime and maintenance costs.

7. Shock and Vibration: Consider the level of shock and vibration the system will experience. The pin coupling should be robust enough to handle these dynamic loads without failure.

8. Cost: Evaluate the overall cost of the pin coupling, including its initial purchase price, maintenance costs, and potential downtime expenses. Choose a coupling that offers the best balance of performance and cost-effectiveness.

9. Material Selection: Select the appropriate materials for the pin coupling based on the application requirements. Common materials include carbon steel, stainless steel, and alloy steel.

10. Compatibility: Ensure that the pin coupling is compatible with the specific shaft sizes and configurations of the system’s driving and driven components.

11. Compliance with Industry Standards: Check if the pin coupling meets relevant industry standards and safety requirements.

By carefully considering these factors, engineers and system designers can choose the most suitable pin coupling for their specific application. It’s essential to work closely with coupling manufacturers or suppliers to ensure that the selected coupling meets all the necessary specifications and requirements.

Understanding Pin Couplings and Their Functionality

A pin coupling, also known as a shear pin coupling, is a type of mechanical coupling used to connect two rotating shafts in a mechanical system. It is designed to transmit torque while allowing for a limited amount of angular misalignment between the shafts. The primary function of a pin coupling is to protect the connected equipment from torque overload and prevent damage to the shafts and other components in case of sudden shock or overload.

How a Pin Coupling Works:

A typical pin coupling consists of two hubs, one on each shaft to be connected, and a series of pins that pass through the hubs to join them together. The pins are usually made of a softer material than the hubs, such as brass or aluminum, to act as sacrificial elements. The number and size of the pins depend on the coupling’s torque rating and the required angular misalignment capacity.

When the shafts are misaligned, the pins experience shear stress as they bend under the applied load. In normal operating conditions, the pins remain intact and allow the torque to transfer from one shaft to another. However, in the event of an overload or excessive misalignment, the pins will shear off, preventing the transmission of excessive torque and protecting the connected equipment from damage.

After shearing, the damaged pins can be easily replaced, and the coupling can be put back into service without major repairs to the equipment. This feature makes pin couplings particularly suitable for applications with varying operating conditions and environments where shock loads or sudden overloads may occur.

Advantages of Pin Couplings:

– Protection against Overload: The shear pins act as a safety feature, protecting the connected equipment from excessive torque and sudden shocks.

– Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts.

– Easy Replacement: After shearing, the damaged pins can be quickly replaced, reducing downtime and maintenance costs.

– Versatility: Suitable for a wide range of applications, including pumps, compressors, and other industrial machinery.

– Cost-Effective: The sacrificial pins are cost-effective components that can be easily replaced, avoiding costly repairs to the main equipment.

Limitations:

– Pin couplings have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings.

– The need to replace the shear pins after each failure may lead to frequent maintenance requirements in applications with frequent overloads or misalignments.

In summary, pin couplings offer a reliable and cost-effective solution for torque transmission and protection against overloads in various mechanical systems. Their ability to accommodate misalignment and absorb shock loads makes them suitable for a wide range of industrial applications.

editor by CX 2024-05-15

China Hot selling Power Transmission Cone Ring Flexible Shaft Connection FCL Pin Flexible Pin & Bush Cone Ring Coupling for Pumps

Product Description

Power Transmission Cone Ring Flexible Shaft Connection FCL Pin Flexible Pin & Bush Cone Ring Coupling for Pumps

The characteristics of FCL Flexible Pin & Bush Coupling

(1)Coupling is simple in structure, convenient installation, easy replacement, small size, light weight.

(2)If the installation adjustment can keep 2 relative displacement within the prescribed limits, then coupling will have satisfactory performance and long service life.

(3) It can be widely applied to all kinds of medium and small power transmission shafts, such as reducer, crane, compressor, conveyor, textile machine, hoist and ball mill, which are not loaded by motors.

(4)The allowable relative displacement of the elastic sleeve pin couplings:

Radial displacement: 0.2~0.6mm angular displacement: 0 ° 30 ‘~1° 30’

Related products:

Production workshop:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can Pin Couplings Accommodate High Torque and High-Speed Applications?

Pin couplings are versatile and robust, making them suitable for a wide range of applications, including those involving high torque and high-speed requirements. However, the specific design and construction of the pin coupling will determine its capacity to handle such demanding conditions.

The ability of a pin coupling to accommodate high torque depends on factors such as the material used, the size and number of pins, and the overall design. High-quality pin couplings are often made from strong and durable materials like alloy steel, which allows them to withstand significant torque loads without failure or deformation.

Similarly, the capability of a pin coupling to handle high speeds depends on factors such as the balance of the coupling and the precise manufacturing of the pins and hubs. Properly balanced pin couplings can operate at higher speeds without generating excessive vibration or causing premature wear.

When selecting a pin coupling for high torque and high-speed applications, it is essential to consider the following:

- Design and Construction: Opt for pin couplings with a robust and well-engineered design to handle the expected torque and speed requirements.

- Material: Choose pin couplings made from high-quality materials known for their strength and fatigue resistance.

- Size: Select an appropriate size of pin coupling that can accommodate the torque and speed expected in the application.

- Manufacturer’s Ratings: Refer to the manufacturer’s specifications and torque-speed curves to ensure the coupling meets the desired performance criteria.

By carefully considering these factors and choosing a pin coupling designed for high torque and high-speed applications, you can ensure reliable and efficient power transmission in demanding industrial settings.

Factors to Consider When Choosing a Pin Coupling for a Specific System

When selecting a pin coupling for a specific system, several critical factors need to be considered to ensure optimal performance, reliability, and longevity. Each application has unique requirements, and choosing the right pin coupling involves assessing the following factors:

1. Torque and Power Requirements: Determine the torque and power transmission requirements of the system. The pin coupling must be capable of handling the maximum torque and power generated by the connected equipment.

2. Operating Speed: Consider the rotational speed of the system’s driving and driven shafts. The pin coupling’s design should allow for smooth and efficient operation at the specified speed range.

3. Misalignment Tolerance: Assess the degree of misalignment between the shafts that the coupling needs to accommodate. Pin couplings are suitable for applications with moderate angular, parallel, and axial misalignment.

4. Operating Environment: Consider the environmental conditions the coupling will be exposed to, including temperature, humidity, dust, and presence of corrosive substances. Choose a pin coupling with materials and surface treatments suitable for the operating environment.

5. Size and Space Constraints: Ensure that the selected pin coupling fits within the available space and does not interfere with other components in the system.

6. Serviceability and Maintenance: Evaluate the ease of installation, maintenance, and replacement of the pin coupling. Easy-to-service couplings can help reduce downtime and maintenance costs.

7. Shock and Vibration: Consider the level of shock and vibration the system will experience. The pin coupling should be robust enough to handle these dynamic loads without failure.

8. Cost: Evaluate the overall cost of the pin coupling, including its initial purchase price, maintenance costs, and potential downtime expenses. Choose a coupling that offers the best balance of performance and cost-effectiveness.

9. Material Selection: Select the appropriate materials for the pin coupling based on the application requirements. Common materials include carbon steel, stainless steel, and alloy steel.

10. Compatibility: Ensure that the pin coupling is compatible with the specific shaft sizes and configurations of the system’s driving and driven components.

11. Compliance with Industry Standards: Check if the pin coupling meets relevant industry standards and safety requirements.

By carefully considering these factors, engineers and system designers can choose the most suitable pin coupling for their specific application. It’s essential to work closely with coupling manufacturers or suppliers to ensure that the selected coupling meets all the necessary specifications and requirements.

Advantages of Using Pin Couplings in Mechanical Systems

Pin couplings, also known as shear pin couplings, offer several advantages when used in mechanical systems. These advantages make them a popular choice for various industrial applications:

- 1. Overload Protection: Pin couplings are designed to provide overload protection to connected equipment. In case of excessive torque or sudden shock loads, the sacrificial pins will shear off, preventing damage to the shafts and other components.

- 2. Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts. This helps to compensate for minor misalignments and reduces the stress on the connected equipment.

- 3. Cost-Effective: The shear pins used in pin couplings are relatively inexpensive compared to other coupling components. In the event of a failure, replacing the damaged pins is a cost-effective solution, avoiding more significant repairs to the main equipment.

- 4. Easy Replacement: After shearing, the damaged pins can be quickly and easily replaced. This leads to reduced downtime and lower maintenance costs in the long run.

- 5. Versatility: Pin couplings are suitable for a wide range of applications, including pumps, compressors, fans, and other industrial machinery. Their ability to handle varying operating conditions makes them versatile in different environments.

- 6. Shock Load Absorption: Pin couplings can absorb and dissipate shock loads effectively. The shear pins act as a buffer, protecting the equipment from sudden impacts or overloads.

Despite their numerous advantages, it is essential to consider the limitations of pin couplings as well. They have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings. Additionally, the need to replace shear pins after each failure may lead to more frequent maintenance requirements in applications with frequent overloads or misalignments.

In conclusion, pin couplings provide reliable torque transmission and safety features, making them a valuable component in various mechanical systems. Their ability to protect against overloads and accommodate misalignments makes them a practical choice in a wide range of industrial applications.

editor by CX 2024-05-15

China manufacturer OEM 2L1w4684AA for CHINAMFG Rubber Pin Flexible Elastic Pin Bush Coupling Shaft Couplings

Product Description

Basic Info.

| Model NO. | 2L1W4684AA | Parts | Auto Parts For Center Support Bearing | |

| Specification | 6*14*120 | Trademark | YTK or Customized | |

| Price | Negotiable | Transport Packing | Neutral Packing & Customized | |

| Exportation | ZheJiang Port | Bearing Quality | ZV3 Level | |

| Warranty | One Year or Above | Laser Mark | Available | |

| Applicable Models | FORD | Production Capacity | 60, 1220843 |

BMW |

| 7L0521403 | Volkswagen Touareg | 245710115 | Mercedes-Benz | |

| 2L1W4684AA 4165078 |

FORD | 95712781 | Hyundai | |

| 12341 | Mercedes-Benz | 26117512619 | BMW | |

| 26117546425 | BMW |

-FAQ:

Q1. What is your terms of packing?

Generally, we pack our goods in neutral boxes and brown cartons or as your demand.

If you have legally registered patent,we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of delivery?

EXW, FOB, CIF, CFR

Q3. How about your delivery time?

Generally, it will take 10 to 30 days after receiving your advance payment.

The specific delivery time depends on the items and the quantity of your order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Condition: | New |

| Color: | Black |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How Do Pin Couplings Compare to Other Types of Couplings in Terms of Performance?

Pin couplings offer certain advantages and disadvantages compared to other types of couplings, and their performance characteristics can vary depending on the specific application requirements. Below is a comparison of pin couplings with some commonly used couplings:

1. Gear Couplings:

- Flexibility: Gear couplings are more rigid than pin couplings and may not offer the same level of misalignment capacity.

- Torsional Stiffness: Gear couplings provide higher torsional stiffness, making them suitable for applications requiring precise torque transmission.

- Shock Absorption: Gear couplings can handle higher shock loads due to their robust design and greater stiffness.

- Maintenance: Gear couplings may require periodic lubrication and maintenance compared to maintenance-free pin couplings.

- Applications: Gear couplings are commonly used in heavy-duty and high-torque applications where precise torque transmission is essential.

2. Flexible (Elastomeric) Couplings:

- Flexibility: Elastomeric couplings offer higher misalignment capacity than pin couplings and can handle angular, parallel, and axial misalignment.

- Shock Absorption: Elastomeric couplings provide excellent shock absorption, damping vibrations, and protecting connected equipment.

- Torsional Stiffness: Elastomeric couplings have lower torsional stiffness compared to pin couplings, making them more forgiving in high shock load applications.

- Installation: Elastomeric couplings are easy to install and require no lubrication, making them maintenance-free.

- Applications: Elastomeric couplings are commonly used in pumps, compressors, and other machinery where vibration isolation is crucial.

3. Rigid Couplings:

- Torsional Stiffness: Rigid couplings provide high torsional stiffness, ensuring accurate torque transmission.

- Misalignment Capacity: Rigid couplings have little to no misalignment capacity and require precise shaft alignment.

- Applications: Rigid couplings are used in applications where precise alignment is essential, such as shaft-to-shaft connections in high-precision systems.

Conclusion:

Pin couplings strike a balance between flexibility and torsional stiffness, making them suitable for applications with moderate misalignment and shock loads. They are often used in general industrial applications, conveyors, and light to medium-duty machinery.

When selecting a coupling for a specific application, it is crucial to consider factors such as misalignment requirements, shock and vibration loads, torsional stiffness, maintenance needs, and the level of precision required. Each coupling type has its strengths and weaknesses, and the appropriate choice will depend on the specific demands of the application.

Factors to Consider When Choosing a Pin Coupling for a Specific System

When selecting a pin coupling for a specific system, several critical factors need to be considered to ensure optimal performance, reliability, and longevity. Each application has unique requirements, and choosing the right pin coupling involves assessing the following factors:

1. Torque and Power Requirements: Determine the torque and power transmission requirements of the system. The pin coupling must be capable of handling the maximum torque and power generated by the connected equipment.

2. Operating Speed: Consider the rotational speed of the system’s driving and driven shafts. The pin coupling’s design should allow for smooth and efficient operation at the specified speed range.

3. Misalignment Tolerance: Assess the degree of misalignment between the shafts that the coupling needs to accommodate. Pin couplings are suitable for applications with moderate angular, parallel, and axial misalignment.

4. Operating Environment: Consider the environmental conditions the coupling will be exposed to, including temperature, humidity, dust, and presence of corrosive substances. Choose a pin coupling with materials and surface treatments suitable for the operating environment.

5. Size and Space Constraints: Ensure that the selected pin coupling fits within the available space and does not interfere with other components in the system.

6. Serviceability and Maintenance: Evaluate the ease of installation, maintenance, and replacement of the pin coupling. Easy-to-service couplings can help reduce downtime and maintenance costs.

7. Shock and Vibration: Consider the level of shock and vibration the system will experience. The pin coupling should be robust enough to handle these dynamic loads without failure.

8. Cost: Evaluate the overall cost of the pin coupling, including its initial purchase price, maintenance costs, and potential downtime expenses. Choose a coupling that offers the best balance of performance and cost-effectiveness.

9. Material Selection: Select the appropriate materials for the pin coupling based on the application requirements. Common materials include carbon steel, stainless steel, and alloy steel.

10. Compatibility: Ensure that the pin coupling is compatible with the specific shaft sizes and configurations of the system’s driving and driven components.

11. Compliance with Industry Standards: Check if the pin coupling meets relevant industry standards and safety requirements.

By carefully considering these factors, engineers and system designers can choose the most suitable pin coupling for their specific application. It’s essential to work closely with coupling manufacturers or suppliers to ensure that the selected coupling meets all the necessary specifications and requirements.

Understanding Pin Couplings and Their Functionality

A pin coupling, also known as a shear pin coupling, is a type of mechanical coupling used to connect two rotating shafts in a mechanical system. It is designed to transmit torque while allowing for a limited amount of angular misalignment between the shafts. The primary function of a pin coupling is to protect the connected equipment from torque overload and prevent damage to the shafts and other components in case of sudden shock or overload.

How a Pin Coupling Works:

A typical pin coupling consists of two hubs, one on each shaft to be connected, and a series of pins that pass through the hubs to join them together. The pins are usually made of a softer material than the hubs, such as brass or aluminum, to act as sacrificial elements. The number and size of the pins depend on the coupling’s torque rating and the required angular misalignment capacity.

When the shafts are misaligned, the pins experience shear stress as they bend under the applied load. In normal operating conditions, the pins remain intact and allow the torque to transfer from one shaft to another. However, in the event of an overload or excessive misalignment, the pins will shear off, preventing the transmission of excessive torque and protecting the connected equipment from damage.

After shearing, the damaged pins can be easily replaced, and the coupling can be put back into service without major repairs to the equipment. This feature makes pin couplings particularly suitable for applications with varying operating conditions and environments where shock loads or sudden overloads may occur.

Advantages of Pin Couplings:

– Protection against Overload: The shear pins act as a safety feature, protecting the connected equipment from excessive torque and sudden shocks.

– Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts.

– Easy Replacement: After shearing, the damaged pins can be quickly replaced, reducing downtime and maintenance costs.

– Versatility: Suitable for a wide range of applications, including pumps, compressors, and other industrial machinery.

– Cost-Effective: The sacrificial pins are cost-effective components that can be easily replaced, avoiding costly repairs to the main equipment.

Limitations:

– Pin couplings have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings.

– The need to replace the shear pins after each failure may lead to frequent maintenance requirements in applications with frequent overloads or misalignments.

In summary, pin couplings offer a reliable and cost-effective solution for torque transmission and protection against overloads in various mechanical systems. Their ability to accommodate misalignment and absorb shock loads makes them suitable for a wide range of industrial applications.

editor by CX 2024-05-15

China Good quality 235 32K Excavator Coupling Machine Parts Track Pin Press Flexible Coupling