Product Description

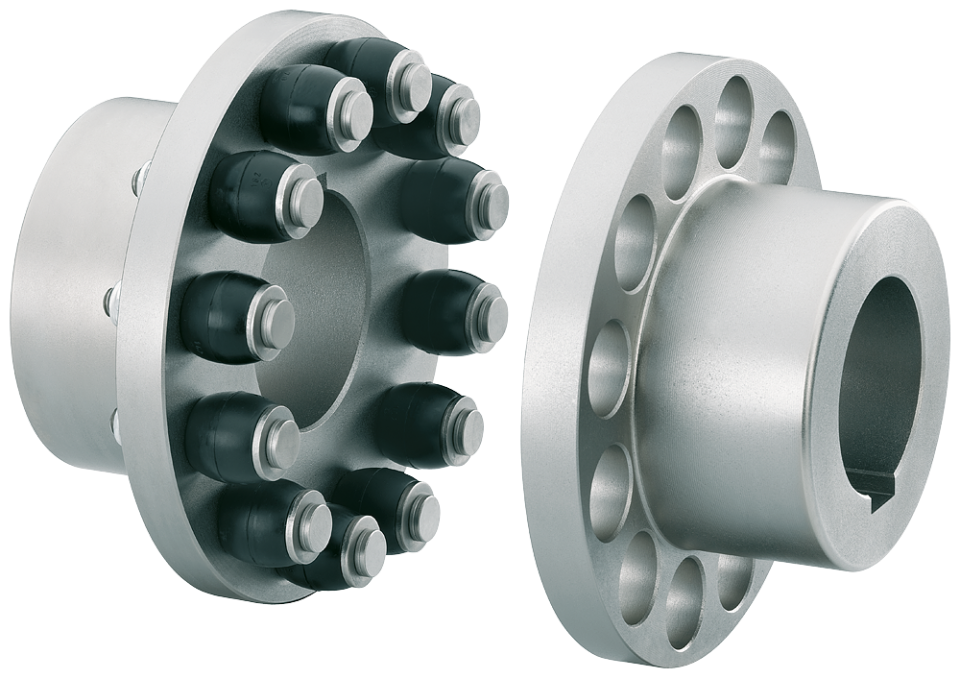

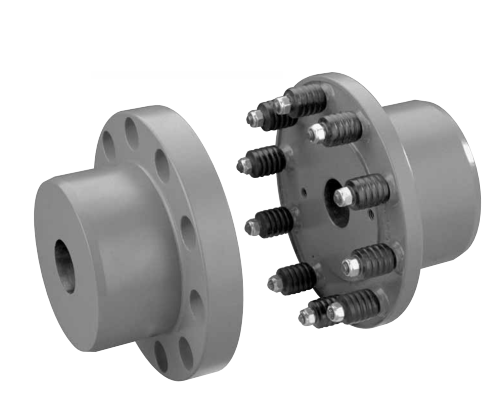

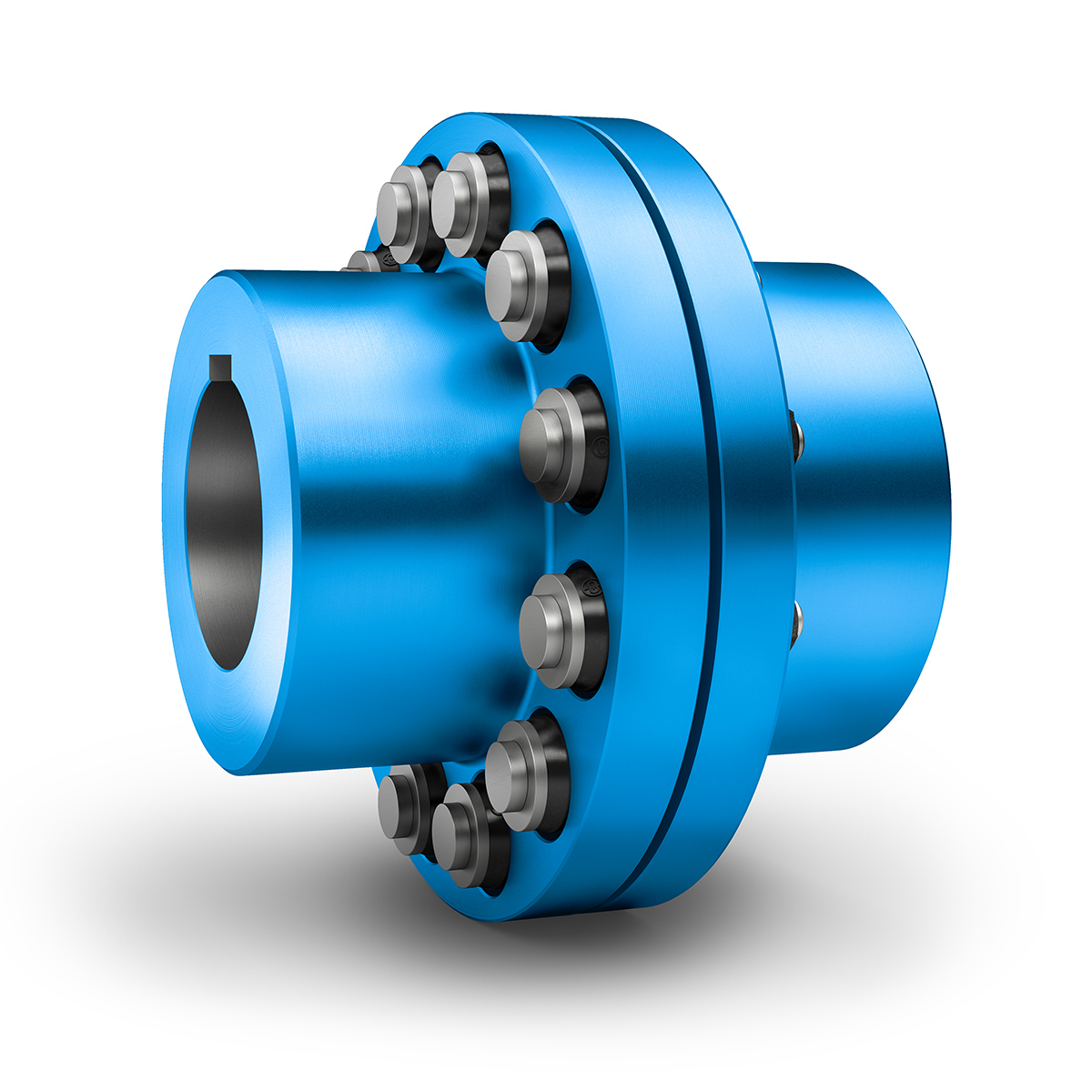

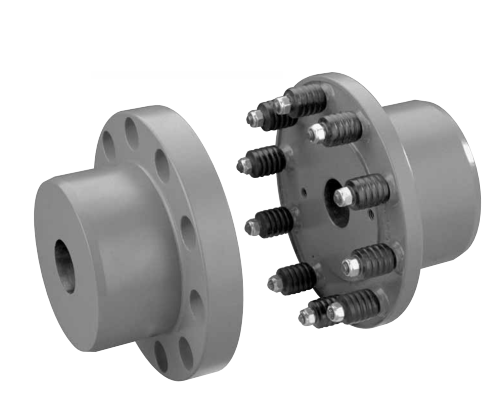

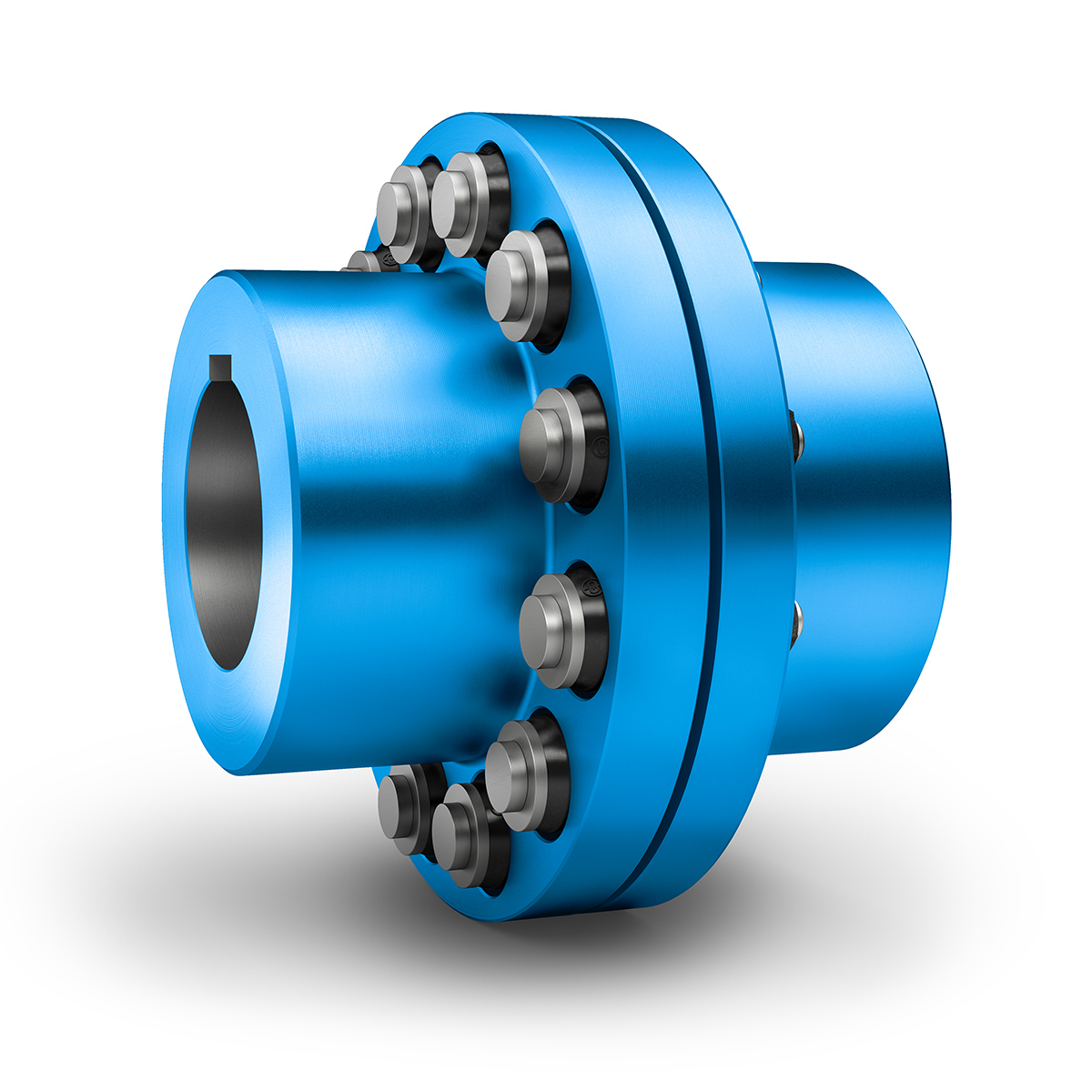

Cast Iron Elastic Pump Shaft Fcl 90~630 Reduced Transmission Rubber Screw Coupling with flange straight bore

Product Description

FCL coupling is widely used for its compact designing,easy installation,convenientmaintenance,small size and light weight.As long as the’relative displacement between shafts is kept within the specified tolerance,the coupling will operate the best function and a longer working life,thus it is greatly demanded in medium and minorpower transmission systems drive by moters,such as speed reducers,hoists,compressor,spining &weaving machines and ball mills,permittable relative displacement:Radial displacement 0.2-0.6mm ; Angel displacemente 0o30′–1o30′

Related products:

Production workshop:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can Pin Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, pin couplings can be used in both horizontal and vertical shaft arrangements. These couplings are designed to accommodate angular misalignment, parallel misalignment, and axial movement, making them versatile for various shaft orientations.

In horizontal shaft arrangements, where the shafts are aligned on the same horizontal plane, pin couplings can efficiently transmit torque while allowing for flexibility to accommodate minor misalignments and shaft movements. The pins and flexible elements in the coupling enable angular displacement and radial flexibility, ensuring smooth power transmission even if the shafts are not perfectly aligned.

In vertical shaft arrangements, where the shafts are aligned on a vertical plane, pin couplings can also be used effectively. The coupling design allows for axial movement, which is crucial in vertical applications where the shafts may experience expansion or contraction due to thermal changes or other factors. The flexible nature of pin couplings allows them to handle these axial movements without compromising the coupling’s performance.

Whether in horizontal or vertical arrangements, pin couplings are commonly used in various industrial applications, including pumps, compressors, conveyors, and other rotating machinery. They are known for their simplicity, ease of installation, and ability to provide reliable power transmission while accommodating misalignment and shaft movement.

When using pin couplings in either arrangement, it is essential to ensure proper alignment and regular maintenance to maximize their performance and service life. Additionally, considering factors like torque requirements, operating conditions, and environmental considerations will help in selecting the appropriate pin coupling for a specific application.

What Industries Commonly Use Pin Couplings for Power Transmission?

Pin couplings are widely used in various industries for power transmission due to their ability to accommodate misalignment and provide reliable torque transmission. Some of the industries where pin couplings are commonly employed include:

- 1. Manufacturing: In manufacturing processes, pin couplings are used in conveyor systems, mixers, agitators, and other machinery to transfer power between motors and driven equipment.

- 2. Pulp and Paper: The pulp and paper industry uses pin couplings in machinery such as pumps, fans, and rotary kilns for continuous power transmission.

- 3. Chemical and Petrochemical: Pin couplings find applications in chemical processing plants, refineries, and petrochemical facilities for various rotating equipment.

- 4. Water and Wastewater: Pin couplings are used in water treatment facilities, pumps, and blowers to transfer power efficiently.

- 5. Steel and Metal Processing: Steel mills and metal processing plants utilize pin couplings in rolling mills, extruders, and other equipment.

- 6. Food and Beverage: Pin couplings are employed in food processing machinery, packaging equipment, and conveyor systems.

- 7. Mining and Quarrying: The mining industry uses pin couplings in crushers, conveyor belts, and various mineral processing equipment.

- 8. Oil and Gas: Pin couplings are used in the oil and gas sector for pumps, compressors, and drilling equipment.

- 9. Power Generation: In power plants, pin couplings are used in turbines, generators, and other power transmission systems.

- 10. Construction and Heavy Equipment: Pin couplings find applications in construction machinery, earthmoving equipment, and other heavy-duty machinery.

- 11. Agriculture: In agricultural machinery, pin couplings are used in tractors, irrigation systems, and grain processing equipment.

These are just some examples of the industries where pin couplings are commonly used. Pin couplings offer versatility, ease of installation, and reliability, making them suitable for a wide range of applications in different sectors where power transmission is essential.

Advantages of Using Pin Couplings in Mechanical Systems

Pin couplings, also known as shear pin couplings, offer several advantages when used in mechanical systems. These advantages make them a popular choice for various industrial applications:

- 1. Overload Protection: Pin couplings are designed to provide overload protection to connected equipment. In case of excessive torque or sudden shock loads, the sacrificial pins will shear off, preventing damage to the shafts and other components.

- 2. Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts. This helps to compensate for minor misalignments and reduces the stress on the connected equipment.

- 3. Cost-Effective: The shear pins used in pin couplings are relatively inexpensive compared to other coupling components. In the event of a failure, replacing the damaged pins is a cost-effective solution, avoiding more significant repairs to the main equipment.

- 4. Easy Replacement: After shearing, the damaged pins can be quickly and easily replaced. This leads to reduced downtime and lower maintenance costs in the long run.

- 5. Versatility: Pin couplings are suitable for a wide range of applications, including pumps, compressors, fans, and other industrial machinery. Their ability to handle varying operating conditions makes them versatile in different environments.

- 6. Shock Load Absorption: Pin couplings can absorb and dissipate shock loads effectively. The shear pins act as a buffer, protecting the equipment from sudden impacts or overloads.

Despite their numerous advantages, it is essential to consider the limitations of pin couplings as well. They have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings. Additionally, the need to replace shear pins after each failure may lead to more frequent maintenance requirements in applications with frequent overloads or misalignments.

In conclusion, pin couplings provide reliable torque transmission and safety features, making them a valuable component in various mechanical systems. Their ability to protect against overloads and accommodate misalignments makes them a practical choice in a wide range of industrial applications.

editor by CX 2024-05-08

China Best Sales Cast Iron Rubber Screw Pin FCL Coupling for Motor

Product Description

Product Description

COUPLINGS

| HRC | FCL | Chain coupling | GE | L | NM | MH | Torque limiter |

| HRC 70B | FCL90 | KC4012 | GE14 | L050 | NM50 | MH45 | TL250-2 |

| HRC 70F | FCL100 | KC4014 | GE19 | L070 | NM67 | MH55 | TL250-1 |

| HRC 70H | FCL112 | KC4016 | GE24 | L075 | NM82 | MH65 | TL350-2 |

| HRC 90B | FCL125 | KC5014 | GE28 | L090 | NM97 | MH80 | TL350-1 |

| HRC 90F | FCL140 | KC5016 | GE38 | L095 | NM112 | MH90 | TL500-2 |

| HRC 90H | FCL160 | KC6018 | GE42 | L099 | NM128 | MH115 | TL500-1 |

| HRC 110B | FCL180 | KC6571 | GE48 | L100 | NM148 | MH130 | TL700-2 |

| HRC 110F | FCL200 | KC6571 | GE55 | L110 | NM168 | MH145 | TL700-1 |

| HRC 110H | FCL224 | KC8018 | GE65 | L150 | NM194 | MH175 | |

| HRC 130B | FCL250 | KC8571 | GE75 | L190 | NM214 | MH200 | |

| HRC 130F | FCL280 | KC8571 | GE90 | L225 | |||

| HRC 130H | FCL315 | KC1571 | |||||

| HRC 150B | FCL355 | KC12018 | |||||

| HRC 150F | FCL400 | KC12571 | |||||

| HRC 150H | FCL450 | ||||||

| HRC 180B | FCL560 | ||||||

| HRC 180F | FCL630 | ||||||

| HRC 180H | |||||||

| HRC 230B | |||||||

| HRC 230F | |||||||

| HRC 230H | |||||||

| HRC 280B | |||||||

| HRC 280F | |||||||

| HRC 280H |

Catalogue

Workshop

Lots of coupling in stock

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: 10-20 days.

2.Production Lead-times: 30-45 days after order confirmed.

Q3: What is your advantages?

1. The most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Structure: | Flexible |

| Material: | Cast Iron |

| Type Name: | FCL |

| Origin: | Zhejiang |

| Customization: |

Available

| Customized Request |

|---|

How Does a Pin Coupling Protect Connected Equipment from Shock Loads and Vibrations?

Pin couplings are designed to provide excellent protection to connected equipment from shock loads and vibrations, ensuring the smooth and reliable operation of the machinery. The unique features of pin couplings contribute to their ability to absorb and dampen shock loads and vibrations effectively:

- Flexibility: Pin couplings possess a certain degree of flexibility due to the presence of movable pins. When subjected to sudden shock loads or vibrations, the pins can flex and move slightly, absorbing the impact and preventing it from transmitting directly to the connected equipment. This flexibility helps in reducing stress and minimizing the risk of damage to the machinery.

- Torsional Compliance: The pin coupling’s design allows for a certain amount of torsional compliance. This means that when the connected shafts experience slight misalignments or angular displacements, the pin coupling can compensate for these variations without causing additional stress or vibration in the system. This feature ensures that the machinery remains in proper alignment even under dynamic conditions, reducing wear and tear.

- Damping Characteristics: The presence of movable pins introduces damping characteristics to the coupling. When vibrations occur in the system, the pins can dampen these oscillations, preventing resonance and the amplification of vibrations. This damping effect improves the overall stability and performance of the machinery.

- Strength and Resilience: High-quality pin couplings are constructed from durable materials with excellent fatigue resistance. This enables the coupling to withstand repeated shock loads and vibrations over an extended period without compromising its integrity. The strength and resilience of the pin coupling contribute to the protection of the connected equipment.

Overall, pin couplings are reliable and versatile components that can effectively protect connected equipment from shock loads and vibrations. Their flexibility, torsional compliance, damping characteristics, and robust construction make them suitable for various industrial applications where shock and vibration mitigation are essential for maintaining the health and longevity of machinery and equipment.

Impact of Pin Coupling on the Overall Reliability of Connected Equipment

A pin coupling plays a crucial role in enhancing the overall reliability and performance of connected equipment in various industrial applications. Its design and construction contribute to several factors that influence reliability:

1. Torque Transmission: Pin couplings efficiently transmit torque between the driving and driven shafts, ensuring smooth power transfer without slippage or loss. This consistent torque transmission helps maintain the stability and reliability of the system during operation.

2. Misalignment Compensation: Pin couplings are designed to accommodate small amounts of angular, parallel, and axial misalignment between shafts. By tolerating misalignment, the coupling reduces stress on connected equipment, bearings, and seals, thereby enhancing reliability and extending the service life of these components.

3. Shock and Vibration Absorption: In applications with dynamic loads, such as pumps, compressors, and heavy machinery, pin couplings help dampen shock and vibrations. By absorbing and reducing these impact forces, the coupling minimizes stress on the system and prevents premature component failure.

4. Simplified Maintenance: Pin couplings generally have a simple design, making them easy to install and maintain. The ease of maintenance ensures that the coupling can be regularly inspected, lubricated, and replaced when necessary, reducing downtime and increasing the overall reliability of the equipment.

5. Corrosion Resistance: Depending on the materials used, pin couplings can be highly resistant to corrosion, making them suitable for use in harsh or corrosive environments. This corrosion resistance prevents degradation of the coupling and its components, enhancing reliability and longevity.

6. Enhanced Durability: High-quality pin couplings are manufactured from robust materials and undergo precise machining processes. These attributes contribute to the coupling’s durability, allowing it to withstand heavy loads and harsh conditions over an extended period.

7. Balanced Design: The design of a pin coupling ensures that the load is evenly distributed between the driving and driven shafts. This balanced load distribution reduces stress concentrations, minimizes wear, and increases the reliability of connected equipment.

8. Compliance with Standards: Reputable pin coupling manufacturers ensure their products comply with industry standards and regulations. Meeting these standards ensures that the coupling is designed and manufactured to specific quality criteria, enhancing reliability and safety.

Overall, a well-selected and properly installed pin coupling can significantly improve the reliability and performance of connected equipment. It helps prevent unexpected failures, reduces downtime, and contributes to the overall efficiency of industrial processes.

Can Pin Couplings Handle Misalignment Between Shafts?

Yes, pin couplings are designed to accommodate a certain degree of misalignment between shafts in rotating machinery. They are considered flexible couplings, which means they can provide some degree of angular, parallel, and axial misalignment capability.

Pin couplings typically consist of two hubs, each connected to a shaft, and a central sleeve with pins that transmit torque between the hubs. The pins allow for a limited range of movement, which helps to compensate for slight misalignments between the shafts.

The angular misalignment capacity of a pin coupling is achieved through the bending of the pins. When the shafts are misaligned at an angle, the pins on one side of the coupling experience bending while those on the opposite side are in tension. The pins are designed to withstand these bending and tension forces within their elastic limits, ensuring proper functioning and longevity of the coupling.

Similarly, the pins can accommodate parallel misalignment by sliding within the pin holes of the coupling’s central sleeve. This sliding action allows the hubs to move slightly relative to each other, compensating for any offset between the shafts.

However, it is essential to note that pin couplings have limitations in terms of the amount of misalignment they can handle. Excessive misalignment beyond their specified limits can lead to increased wear on the pins and other coupling components, reducing the coupling’s effectiveness and potentially causing premature failure.

While pin couplings are suitable for applications with moderate misalignment requirements, they may not be the best choice for applications with significant misalignment or where precise alignment is critical. In such cases, more flexible couplings like gear or elastomeric couplings may be more appropriate.

Overall, when considering the use of pin couplings, it is essential to carefully evaluate the specific misalignment requirements of the application and select a coupling that can adequately accommodate those misalignments while ensuring reliable and efficient power transmission.

editor by CX 2024-04-08

China Custom FCL140 Cast Iron Flexible Rubber Couplings Rubber Screw Pin Coupling for Pump

Product Description

Product Description

Company profile

HangZhou Terry Machinery Co.Ltd is a leading supplier of bearings, Linear motion system for CNC , Ball transfer Unit

and transmission component .the growing industrial and Favorable policy of HangZhou benefit the development of Terry

Machinery .Our products are utilized in industrial, motorcycle, vehicle and Automation applications. Now we are exporting

to 46 countries.including USA, GBR , Germany , Spain, Poland ,Turkey ect .The Goal of Terry Machinery to provide out

customers with widest range of products at competitive prices, backed with the best Service.OUR ADVANTAGE Products

Our major products & Supplied:Meet all the international standards and ISO9001 -TS1694 Certificate Big volume in Stock,

No MOQ required Personnel Our salespersons are well trained to accommodate your requests and speak English for your

conveniences.Our technicians and engineers Experience in the Industry area exceeds 23 years Service &Quality control ,

We supply detailed drawings and offer when ever necessary,We help all customers promote and improve their sales.We

inspect every piece of products by ourselves before delivery.

Customer Praise

FAQ

| Material: | Cast Iron |

|---|---|

| Flexible or Rigid: | Flexible |

| Weight: | 5.81kg |

| Length: | 100mm |

| Outer Diameter: | 140mm |

| Certification: | So9001/ISO9000 |

| Samples: |

US$ 55/Piece

1 Piece(Min.Order) | |

|---|

Are There Any Safety Considerations When Using Pin Couplings in Rotating Machinery?

Yes, there are several safety considerations to keep in mind when using pin couplings in rotating machinery. These considerations are essential to ensure the safe and efficient operation of the equipment and to protect personnel working in the vicinity. Here are some key safety points to consider:

- Guarding: When installing pin couplings, it is crucial to provide adequate guarding around the coupling area. This helps prevent accidental contact with the rotating coupling components, such as pins and hubs, which could cause severe injuries.

- Maintenance and Inspection: Regular maintenance and inspection of the pin coupling are vital to identify any signs of wear, misalignment, or damage. Any worn or damaged components should be replaced immediately to prevent coupling failure, which could lead to sudden equipment shutdown or safety hazards.

- Proper Alignment: Ensuring precise alignment of the connected shafts is crucial to the safe operation of the pin coupling. Misalignment can lead to increased stresses and premature wear on the coupling components, resulting in potential failures.

- Torque and Speed Limits: Adhering to the manufacturer’s recommended torque and speed limits for the pin coupling is essential for its safe operation. Exceeding these limits can lead to overloading and failure of the coupling.

- Environmental Considerations: Take into account the operating environment when selecting a pin coupling. Extreme temperatures, corrosive atmospheres, or harsh conditions may require special materials or coatings to ensure the coupling’s integrity and prevent premature failure.

- Training and Awareness: Operators and maintenance personnel should receive proper training on the safe handling, installation, and maintenance of pin couplings. Awareness of potential hazards and safety protocols is crucial for the safe use of rotating machinery.

- Emergency Shutdown: Install emergency shutdown systems that can quickly stop the rotating machinery in case of any safety concerns or abnormal conditions.

- Compliance with Regulations: Ensure that the use of pin couplings complies with all relevant safety and industry regulations and standards.

By taking these safety considerations into account and implementing proper safety measures, the use of pin couplings in rotating machinery can be done safely and effectively, mitigating potential risks and ensuring a safe working environment for personnel.

Factors to Consider When Choosing a Pin Coupling for a Specific System

When selecting a pin coupling for a specific system, several critical factors need to be considered to ensure optimal performance, reliability, and longevity. Each application has unique requirements, and choosing the right pin coupling involves assessing the following factors:

1. Torque and Power Requirements: Determine the torque and power transmission requirements of the system. The pin coupling must be capable of handling the maximum torque and power generated by the connected equipment.

2. Operating Speed: Consider the rotational speed of the system’s driving and driven shafts. The pin coupling’s design should allow for smooth and efficient operation at the specified speed range.

3. Misalignment Tolerance: Assess the degree of misalignment between the shafts that the coupling needs to accommodate. Pin couplings are suitable for applications with moderate angular, parallel, and axial misalignment.

4. Operating Environment: Consider the environmental conditions the coupling will be exposed to, including temperature, humidity, dust, and presence of corrosive substances. Choose a pin coupling with materials and surface treatments suitable for the operating environment.

5. Size and Space Constraints: Ensure that the selected pin coupling fits within the available space and does not interfere with other components in the system.

6. Serviceability and Maintenance: Evaluate the ease of installation, maintenance, and replacement of the pin coupling. Easy-to-service couplings can help reduce downtime and maintenance costs.

7. Shock and Vibration: Consider the level of shock and vibration the system will experience. The pin coupling should be robust enough to handle these dynamic loads without failure.

8. Cost: Evaluate the overall cost of the pin coupling, including its initial purchase price, maintenance costs, and potential downtime expenses. Choose a coupling that offers the best balance of performance and cost-effectiveness.

9. Material Selection: Select the appropriate materials for the pin coupling based on the application requirements. Common materials include carbon steel, stainless steel, and alloy steel.

10. Compatibility: Ensure that the pin coupling is compatible with the specific shaft sizes and configurations of the system’s driving and driven components.

11. Compliance with Industry Standards: Check if the pin coupling meets relevant industry standards and safety requirements.

By carefully considering these factors, engineers and system designers can choose the most suitable pin coupling for their specific application. It’s essential to work closely with coupling manufacturers or suppliers to ensure that the selected coupling meets all the necessary specifications and requirements.

Understanding Pin Couplings and Their Functionality

A pin coupling, also known as a shear pin coupling, is a type of mechanical coupling used to connect two rotating shafts in a mechanical system. It is designed to transmit torque while allowing for a limited amount of angular misalignment between the shafts. The primary function of a pin coupling is to protect the connected equipment from torque overload and prevent damage to the shafts and other components in case of sudden shock or overload.

How a Pin Coupling Works:

A typical pin coupling consists of two hubs, one on each shaft to be connected, and a series of pins that pass through the hubs to join them together. The pins are usually made of a softer material than the hubs, such as brass or aluminum, to act as sacrificial elements. The number and size of the pins depend on the coupling’s torque rating and the required angular misalignment capacity.

When the shafts are misaligned, the pins experience shear stress as they bend under the applied load. In normal operating conditions, the pins remain intact and allow the torque to transfer from one shaft to another. However, in the event of an overload or excessive misalignment, the pins will shear off, preventing the transmission of excessive torque and protecting the connected equipment from damage.

After shearing, the damaged pins can be easily replaced, and the coupling can be put back into service without major repairs to the equipment. This feature makes pin couplings particularly suitable for applications with varying operating conditions and environments where shock loads or sudden overloads may occur.

Advantages of Pin Couplings:

– Protection against Overload: The shear pins act as a safety feature, protecting the connected equipment from excessive torque and sudden shocks.

– Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts.

– Easy Replacement: After shearing, the damaged pins can be quickly replaced, reducing downtime and maintenance costs.

– Versatility: Suitable for a wide range of applications, including pumps, compressors, and other industrial machinery.

– Cost-Effective: The sacrificial pins are cost-effective components that can be easily replaced, avoiding costly repairs to the main equipment.

Limitations:

– Pin couplings have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings.

– The need to replace the shear pins after each failure may lead to frequent maintenance requirements in applications with frequent overloads or misalignments.

In summary, pin couplings offer a reliable and cost-effective solution for torque transmission and protection against overloads in various mechanical systems. Their ability to accommodate misalignment and absorb shock loads makes them suitable for a wide range of industrial applications.

editor by CX 2023-10-06

China Good quality FCL140 Cast Iron Flexible Rubber Couplings Rubber Screw Pin Coupling for Pump

Product Description

Product Description

Company profile

HangZhou Terry Machinery Co.Ltd is a leading supplier of bearings, Linear motion system for CNC , Ball transfer Unit

and transmission component .the growing industrial and Favorable policy of HangZhou benefit the development of Terry

Machinery .Our products are utilized in industrial, motorcycle, vehicle and Automation applications. Now we are exporting

to 46 countries.including USA, GBR , Germany , Spain, Poland ,Turkey ect .The Goal of Terry Machinery to provide out

customers with widest range of products at competitive prices, backed with the best Service.OUR ADVANTAGE Products

Our major products & Supplied:Meet all the international standards and ISO9001 -TS1694 Certificate Big volume in Stock,

No MOQ required Personnel Our salespersons are well trained to accommodate your requests and speak English for your

conveniences.Our technicians and engineers Experience in the Industry area exceeds 23 years Service &Quality control ,

We supply detailed drawings and offer when ever necessary,We help all customers promote and improve their sales.We

inspect every piece of products by ourselves before delivery.

Customer Praise

FAQ

| Material: | Cast Iron |

|---|---|

| Flexible or Rigid: | Flexible |

| Weight: | 5.81kg |

| Length: | 100mm |

| Outer Diameter: | 140mm |

| Certification: | So9001/ISO9000 |

| Samples: |

US$ 55/Piece

1 Piece(Min.Order) | |

|---|

What Are the Maintenance Requirements for Pin Couplings?

Pin couplings are known for their simplicity and ease of maintenance. Regular maintenance helps ensure the longevity and optimal performance of pin couplings in various mechanical systems. Here are the key maintenance requirements for pin couplings:

- Lubrication: Most pin couplings require periodic lubrication to reduce friction between the pins and the coupling hubs. Lubrication helps prevent wear and corrosion, ensuring smooth operation.

- Inspection: Regular visual inspections are essential to identify any signs of wear, misalignment, or damage. Inspecting the pins, coupling hubs, and surrounding components can help detect potential issues early on.

- Torque Check: It is crucial to periodically check and retighten the bolts or screws that secure the coupling to the shafts. Loose fasteners can lead to misalignment and coupling failure.

- Alignment: Proper shaft alignment is critical for the effective functioning of pin couplings. Regularly check and adjust the alignment if necessary to minimize wear and vibrations.

- Environmental Protection: In harsh environments or corrosive conditions, take measures to protect the pin coupling from contaminants or chemicals that could cause damage.

- Replacement of Worn Components: When any of the coupling components, such as pins or hubs, show signs of significant wear, they should be replaced promptly to prevent further damage.

It is important to follow the manufacturer’s maintenance guidelines and recommendations for the specific type of pin coupling used in the application. Regular maintenance not only ensures the smooth operation of the coupling but also helps prevent unexpected breakdowns and reduces the risk of costly downtime. Proper maintenance can extend the service life of pin couplings and contribute to the overall reliability of the connected equipment.

Factors to Consider When Choosing a Pin Coupling for a Specific System

When selecting a pin coupling for a specific system, several critical factors need to be considered to ensure optimal performance, reliability, and longevity. Each application has unique requirements, and choosing the right pin coupling involves assessing the following factors:

1. Torque and Power Requirements: Determine the torque and power transmission requirements of the system. The pin coupling must be capable of handling the maximum torque and power generated by the connected equipment.

2. Operating Speed: Consider the rotational speed of the system’s driving and driven shafts. The pin coupling’s design should allow for smooth and efficient operation at the specified speed range.

3. Misalignment Tolerance: Assess the degree of misalignment between the shafts that the coupling needs to accommodate. Pin couplings are suitable for applications with moderate angular, parallel, and axial misalignment.

4. Operating Environment: Consider the environmental conditions the coupling will be exposed to, including temperature, humidity, dust, and presence of corrosive substances. Choose a pin coupling with materials and surface treatments suitable for the operating environment.

5. Size and Space Constraints: Ensure that the selected pin coupling fits within the available space and does not interfere with other components in the system.

6. Serviceability and Maintenance: Evaluate the ease of installation, maintenance, and replacement of the pin coupling. Easy-to-service couplings can help reduce downtime and maintenance costs.

7. Shock and Vibration: Consider the level of shock and vibration the system will experience. The pin coupling should be robust enough to handle these dynamic loads without failure.

8. Cost: Evaluate the overall cost of the pin coupling, including its initial purchase price, maintenance costs, and potential downtime expenses. Choose a coupling that offers the best balance of performance and cost-effectiveness.

9. Material Selection: Select the appropriate materials for the pin coupling based on the application requirements. Common materials include carbon steel, stainless steel, and alloy steel.

10. Compatibility: Ensure that the pin coupling is compatible with the specific shaft sizes and configurations of the system’s driving and driven components.

11. Compliance with Industry Standards: Check if the pin coupling meets relevant industry standards and safety requirements.

By carefully considering these factors, engineers and system designers can choose the most suitable pin coupling for their specific application. It’s essential to work closely with coupling manufacturers or suppliers to ensure that the selected coupling meets all the necessary specifications and requirements.

Advantages of Using Pin Couplings in Mechanical Systems

Pin couplings, also known as shear pin couplings, offer several advantages when used in mechanical systems. These advantages make them a popular choice for various industrial applications:

- 1. Overload Protection: Pin couplings are designed to provide overload protection to connected equipment. In case of excessive torque or sudden shock loads, the sacrificial pins will shear off, preventing damage to the shafts and other components.

- 2. Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts. This helps to compensate for minor misalignments and reduces the stress on the connected equipment.

- 3. Cost-Effective: The shear pins used in pin couplings are relatively inexpensive compared to other coupling components. In the event of a failure, replacing the damaged pins is a cost-effective solution, avoiding more significant repairs to the main equipment.

- 4. Easy Replacement: After shearing, the damaged pins can be quickly and easily replaced. This leads to reduced downtime and lower maintenance costs in the long run.

- 5. Versatility: Pin couplings are suitable for a wide range of applications, including pumps, compressors, fans, and other industrial machinery. Their ability to handle varying operating conditions makes them versatile in different environments.

- 6. Shock Load Absorption: Pin couplings can absorb and dissipate shock loads effectively. The shear pins act as a buffer, protecting the equipment from sudden impacts or overloads.

Despite their numerous advantages, it is essential to consider the limitations of pin couplings as well. They have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings. Additionally, the need to replace shear pins after each failure may lead to more frequent maintenance requirements in applications with frequent overloads or misalignments.

In conclusion, pin couplings provide reliable torque transmission and safety features, making them a valuable component in various mechanical systems. Their ability to protect against overloads and accommodate misalignments makes them a practical choice in a wide range of industrial applications.

editor by CX 2023-08-07

China Good quality EMT Couplings Set Screw Type Zinc Die Cast/Connector/Couplings coupling alignment

Product Description

ALEX is a brand driven by our commitment to enhancing the overall well-being of society, rather than simply chasing profits.

————————————————————————————————————————————————————

Superior Quality: At ALEX, our top priority is ensuring the highest level of quality for each and every product we sell. We are a brand driven by our commitment to enhancing the overall well-being of society, rather than simply chasing profits. We recognize that substandard products can pose risks and inconveniences to people. That’s why CZPT has a dedicated team of professionals focused on rigorous quality control. From meticulous raw material selection to careful loading of finished products into containers, we maintain constant vigilance over the quality of our products.

————————————————————————————————————————————————————

Product Description

CONDUIT FITTINGS

Zinc Die Cast EMT Couplings-Set Screw

Application

Use to couple 2 ends of EMT

Material/Finish

Material: Zinc Die Cast

Finish: Ball burnished, mirror smooth

About this product, we also have Material in Aluminum and Steel.

| CAT# | SIZE | |

| TC-511 | 1/2″ | |

| TC-512 | 3/4″ | |

| TC-513 | 1″ | |

| TC-514 | 1-1/4″ | |

| TC-515 | 1-1/2″ | |

| TC-516 | 2″ | |

| TC-517 | 2-1/2″ | |

| TC-518 | 3″ | |

| TC-520 | 4″ |

Company Profile-Three Companies and a famous Brand Name – ALEX

HangZhou TIMES IMPORT & EXPORT CO., LTD.

TIMES is our foreign trade company. With 25 years of experience in foreign trade, we have established a strong reputation for delivering goods on time and maintaining high quality at reasonable prices. Our service and quality have been proven by the market for the past decades. Our commitment to customer satisfaction has earned us a loyal client base.

HangZhou CZPT ELECTRIC CO., LTD.

Alex Electric is our esteemed manufacturer dedicated to producing our flagship products, which include a wide range of Steel and PVC Conduit Boxes & Covers. Our selection comprises 4” Square Conduit Boxes, 4” Rectangular Conduit Boxes, 4” Octagonal Conduit Boxes, and more.

In addition, CZPT Electric offers an impressive array of products such as Nema Enclosures, Distribution Boxes, and Aluminum Conduit & Weatherproof Boxes like FSB, TGB, DTB, DB, LL/LR/LB/T/C. Over the past decades, we have invested significant resources in the research and development of Switch Panel and Sockets. As a result, our products have gained immense popularity across North/South America, the Middle East, and South-East Asia.

With our extensive product range, we proudly cater to the diverse needs of the electrical industry, providing comprehensive solutions for our valued customers.

HangZhou FRXIHU (WEST LAKE) DIS.S CONDUIT INDUSTRIES CO., LTD.

Francis Conduit is THE largest manufacturer specializing in a wide range of high-quality electrical conduit pipes. We take great pride in producing American standard and British standard products, offering a comprehensive selection that includes EMT Conduit, IMC Conduit, BS4568 Conduit, BS31 Conduit, Flexible Steel Conduit, PVC Coated Flexible Conduit, Liquid Tight Flexible Steel Conduit, Non-Metallic Liquid Tight Conduit, as well as a diverse range of accessories such as connectors and couplings.

Additionally, we place significant emphasis on CZPT Strut Channel & Support, recognizing its importance in the industry. Our portfolio features exceptional products like Cable Trays, G.I Trunking, and C-Channels, which have gained prominence as our flagship offerings.

————————————————————————————————————————————————————

Team Members: 251 Team Members

Shipping Ports: HangZhou, ZheJiang , or ZheJiang

Payment Terms: 30% T/T deposit, balance against copy of B/L

Production Cycle: 3-4 weeks

Delivery Time: Within 4 weeks of receiving your deposit

Packaging: Customized according to your requirements

Certificates

We have received the ISO9001 certificate for our factory and CE certificates for our products.

We sincerely invite people and seek joint development!

Thanks a lot & Best Regards

Feel Free to Check Out & Follow our Youtube Account: CZPT EMT

The CZPT brand is currently seeking suitable exclusive distributors worldwide. We encourage everyone to actively reach out and establish contact with us.

| Connection: | Flange |

|---|---|

| Structure: | Oldham |

| Flexible or Rigid: | Flexible |

| Material: | Zinc |

| Standard: | Nonstandard |

| Craft: | Die Casting |

| Customization: |

Available

| Customized Request |

|---|

What Is a Coupling?

A coupling is a device used to connect two shafts. It transmits power between them and allows for some misalignment or end movement. There are several types of couplings. The most common ones are gear couplings and planetary couplings. However, there are many others as well.

Transfer of energy

Energy coupling is a process by which two biological reactions are linked by sharing energy. The energy released during one reaction can be used to drive the second. It is a very useful mechanism that synchronizes two biological systems. All cells have two types of reactions, exergonic and endergonic, and they are connected through energy coupling.

This process is important for a number of reasons. The first is that it allows the exchange of electrons and their energy. In a single molecule, this energy transfer involves the exchange of two electrons of different energy and spin. This exchange occurs because of the overlap interaction of two MOs.

Secondly, it is possible to achieve quadratic coupling. This is a phenomenon that occurs in circular membrane resonators when the system is statically deflected. This phenomenon has been gaining a great deal of interest as a mechanism for stronger coupling. If this mechanism is employed in a physical system, energy can be transferred on a nanometer scale.

The magnetic field is another important factor that affects the exchange of energy between semiconductor QWs. A strong magnetic field controls the strength of the coupling and the energy order of the exciton. The magnetic field can also influence the direction of polariton-mediated energy transfer. This mechanism is very promising for controlling the routing of excitation in a semiconductor.

Functions

Couplings play a variety of functions, including transferring power, compensating for misalignment, and absorbing shock. These functions depend on the type of shaft being coupled. There are four basic types: angular, parallel, and symmetrical. In many cases, coupling is necessary to accommodate misalignment.

Couplings are mechanical devices that join two rotating pieces of equipment. They are used to transfer power and allow for a small degree of end-to-end misalignment. This allows them to be used in many different applications, such as the transmission from the gearbox to the differential in an automobile. In addition, couplings can be used to transfer power to spindles.

Types

There are two main types of couplings: rigid and flexible. Rigid couplings are designed to prevent relative motion between the two shafts and are suitable for applications where precise alignment is required. However, high stresses in the case of significant misalignment can cause early failure of the coupling. Flexible couplings, on the other hand, allow for misalignment and allow for torque transmission.

A software application may exhibit different types of coupling. The first type involves the use of data. This means that one module may use data from another module for its operation. A good example of data coupling is the inheritance of an object. In a software application, one module can use another module’s data and parameters.

Another type of coupling is a rigid sleeve coupling. This type of coupling has a pipe with a bore that is finished to a specified tolerance. The pipe contains two threaded holes for transmitting torque. The sleeve is secured by a gib head key. This type of coupling may be used in applications where a couple of shafts are close together.

Other types of coupling include common and external. Common coupling occurs when two modules share global data and communication protocols. This type of coupling can lead to uncontrollable error propagation and unforeseen side effects when changes are made to the system. External coupling, on the other hand, involves two modules sharing an external device interface or communication protocol. Both types of coupling involve a shared code structure and depend on the external modules or hardware.

Mechanical couplings are essential in power transmission. They connect rotating shafts and can either be rigid or flexible, depending on the accuracy required. These couplings are used in pumps, compressors, motors, and generators to transmit power and torque. In addition to transferring power, couplings can also prevent torque overload.

Applications

Different coupling styles are ideal for different applications, and they have different characteristics that influence the coupling’s reliability during operation. These characteristics include stiffness, misalignment capability, ease of installation and maintenance, inherent balance, and speed capability. Selecting the right coupling style for a particular application is essential to minimize performance problems and maximize utility.

It is important to know the requirements for the coupling you choose before you start shopping. A proper selection process takes into account several design criteria, including torque and rpm, acoustic signals, and environmental factors. Once you’ve identified these parameters, you can select the best coupling for the job.

A gear coupling provides a mechanical connection between two rotating shafts. These couplings use gear mesh to transmit torque and power between two shafts. They’re typically used on large industrial machines, but they can also be used in smaller motion control systems. In smaller systems, a zero-backlash coupling design is ideal.

Another type of coupling is the flange coupling. These are easy to manufacture. Their design is similar to a sleeve coupling. But unlike a sleeve coupling, a flange coupling features a keyway on one side and two threaded holes on the other. These couplings are used in medium-duty industrial applications.

Besides being useful for power transmission, couplings can also prevent machine vibration. If vibration occurs in a machine, it can cause it to deviate from its predetermined position, or damage the motor. Couplings, however, help prevent this by absorbing the vibration and shock and preventing damage to expensive parts.

Couplings are heavily used in the industrial machinery and electrical industries. They provide the necessary rotation mechanism required by machinery and other equipment. Coupling suppliers can help customers find the right coupling for a specific application.

Criteria for selecting a coupling

When selecting a coupling for a specific application, there are a number of different factors to consider. These factors vary greatly, as do operating conditions, so selecting the best coupling for your system can be challenging. Some of these factors include horsepower, torque, and speed. You also need to consider the size of the shafts and the geometry of the equipment. Space restrictions and maintenance and installation requirements should also be taken into account. Other considerations can be specific to your system, such as the need for reversing.

First, determine what size coupling you need. The coupling’s size should be able to handle the torque required by the application. In addition, determine the interface connection, such as straight or tapered keyed shafts. Some couplings also feature integral flange connections.

During the specification process, be sure to specify which materials the coupling will be made of. This is important because the material will dictate most of its performance characteristics. Most couplings are made of stainless steel or aluminum, but you can also find ones made of Delrin, titanium, or other engineering-grade materials.

One of the most important factors to consider when selecting a coupling is its torque capability. If the torque rating is not adequate, the coupling can be damaged or break easily. Torque is a major factor in coupling selection, but it is often underestimated. In order to ensure maximum coupling performance, you should also take into consideration the size of the shafts and hubs.

In some cases, a coupling will need lubrication throughout its lifecycle. It may need to be lubricated every six months or even once a year. But there are couplings available that require no lubrication at all. An RBI flexible coupling by CZPT is one such example. Using a coupling of this kind can immediately cut down your total cost of ownership.

editor by CX 2023-07-31

China Standard EMT Steel Set Screw Coupling coupling assembly

Product Description

EMT Steel Set Screw Coupling

Basic details:

| Material: | Steel |

| Finish: | Zinc Plated |

| Type: | Set Screw |

|

Color: |

Silver |

| Size: |

1/2”-4” |

|

Usage: |

For use to boupie 2 ends of EMT |

| Brand Name: |

TOPELE |

| Standard: | UL No.E506415 |

Specifications:

| Item No. | Trade Size | Depth(Inch) | Width(Inch) |

| SSCP-50S | 1/2” | 1.680 | 0.722 |

| SSCP-75S | 3/4” | 2.120 | 0.961 |

| SSCP-100S | 1” | 2.498 | 1.185 |

| SSCP-125S | 1-1/4” | 3.250 | 1.541 |

| SSCP-150S | 1-1/2” | 3.745 | 1.785 |

| SSCP-200S | 2” | 4.000 | 2.217 |

| SSCP-250S | 2-1/2” | 4.248 | 2.818 |

| SSCP-300S | 3” | 4.500 | 3.550 |

| SSCP-400S | 4” | 5.000 | 4.550 |

TOPELE EMT Steel Set Screw coupling is used in dry locations to connect the ends of 2 EMT conduits together to extend the raceway. The steel construction ensures mechanical protection and connection between 1 conduit to another.In addition,in damp locations,set-screw couplings are of excellent corrosion protection with zinc electroplated.UL passed to ensure the quality.

FAQ

Q1: Are you manufacture?

A: Yes,we have factory and warehouse in HangZhou HangZhou city.

Q2: How can I request product samples?

A: The samples are free but courier charge will be collected. Please send us samples list and courier account number.

Q3: How can I request a product catalog?

A: The hard copies of catalogs are free but courier charge will be collected.

The PDF catalog we can send to you by email or WeTransfer.

Q4: What is your payment terms?

A: 30% T/T deposit,balance against B/L faxed copy;

Irrevocable L/C 100% at sight and irrevocable.

Q5: How about the delivery time?

A: Accord to your order list and quantity,mostly delivery in 30days.

Why choose us?

1. We are China Leading supply of Electrical Pipe,Strut Channel and Fittings.

2. CZPT is famous brand and already approved by project engineer in different country.

3. Inspected by the Inspection Institution of UL Certification.

4. 100% QC inspection before Shipment.

5. Best Quality & Best Service with Competitive price.

| Color: | Silver |

|---|---|

| IP Rating: | IP68 |

| Surface Treatment: | Galvanised |

| Application: | Boupie Two Ends of EMT |

| Material: | Steel |

| Certification: | UL No.E506415 |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Functions and Modifications of Couplings

A coupling is a mechanical device that connects two shafts and transmits power. Its main purpose is to join two rotating pieces of equipment together, and it can also be used to allow some end movement or misalignment. There are many different types of couplings, each serving a specific purpose.

Functions

Functions of coupling are useful tools to study the dynamical interaction of systems. These functions have a wide range of applications, ranging from electrochemical processes to climate processes. The research being conducted on these functions is highly interdisciplinary, and experts from different fields are contributing to this issue. As such, this issue will be of interest to scientists and engineers in many fields, including electrical engineering, physics, and mathematics.

To ensure the proper coupling of data, coupling software must perform many essential functions. These include time interpolation and timing, and data exchange between the appropriate nodes. It should also guarantee that the time step of each model is divisible by the data exchange interval. This will ensure that the data exchange occurs at the proper times.

In addition to transferring power, couplings are also used in machinery. In general, couplings are used to join two rotating pieces. However, they can also have other functions, including compensating for misalignment, dampening axial motion, and absorbing shock. These functions determine the coupling type required.

The coupling strength can also be varied. For example, the strength of the coupling can change from negative to positive. This can affect the mode splitting width. Additionally, coupling strength is affected by fabrication imperfections. The strength of coupling can be controlled with laser non-thermal oxidation and water micro-infiltration, but these methods have limitations and are not reversible. Thus, the precise control of coupling strength remains a major challenge.

Applications

Couplings transmit power from a driver to the driven piece of equipment. The driver can be an electric motor, steam turbine, gearbox, fan, or pump. A coupling is often the weak link in a pump assembly, but replacing it is less expensive than replacing a sheared shaft.

Coupling functions have wide applications, including biomedical and electrical engineering. In this book, we review some of the most important developments and applications of coupling functions in these fields. We also discuss the future of the field and the implications of these discoveries. This is a comprehensive review of recent advances in coupling functions, and will help guide future research.

Adaptable couplings are another type of coupling. They are made up of a male and female spline in a polymeric material. They can be mounted using traditional keys, keyways, or taper bushings. For applications that require reversal, however, keyless couplings are preferable. Consider your process speed, maximum load capacity, and torque when choosing an adaptable coupling.

Coupling reactions are also used to make pharmaceutical products. These chemical reactions usually involve the joining of two chemical species. In most cases, a metal catalyst is used. The Ullmann reaction, for instance, is an important example of a hetero-coupling reaction. This reaction involves an organic halide with an organometallic compound. The result is a compound with the general formula R-M-R. Another important coupling reaction involves the Suzuki coupling, which unites two chemical species.

In engineering, couplings are mechanical devices that connect two shafts. Couplings are important because they enable the power to be transmitted from one end to the other without allowing a shaft to separate during operation. They also reduce maintenance time. Proper selection, installation, and maintenance, will reduce the amount of time needed to repair a coupling.

Maintenance

Maintenance of couplings is an important part of the lifecycle of your equipment. It’s important to ensure proper alignment and lubrication to keep them running smoothly. Inspecting your equipment for signs of wear can help you identify problems before they cause downtime. For instance, improper alignment can lead to uneven wear of the coupling’s hubs and grids. It can also cause the coupling to bind when you rotate the shaft manually. Proper maintenance will extend the life of your coupling.

Couplings should be inspected frequently and thoroughly. Inspections should go beyond alignment checks to identify problems and recommend appropriate repairs or replacements. Proper lubrication is important to protect the coupling from damage and can be easily identified using thermography or vibration analysis. In addition to lubrication, a coupling that lacks lubrication may require gaskets or sealing rings.

Proper maintenance of couplings will extend the life of the coupling by minimizing the likelihood of breakdowns. Proper maintenance will help you save money and time on repairs. A well-maintained coupling can be a valuable asset for your equipment and can increase productivity. By following the recommendations provided by your manufacturer, you can make sure your equipment is operating at peak performance.

Proper alignment and maintenance are critical for flexible couplings. Proper coupling alignment will maximize the life of your equipment. If you have a poorly aligned coupling, it may cause other components to fail. In some cases, this could result in costly downtime and increased costs for the company.

Proper maintenance of couplings should be done regularly to minimize costs and prevent downtime. Performing periodic inspections and lubrication will help you keep your equipment in top working order. In addition to the alignment and lubrication, you should also inspect the inside components for wear and alignment issues. If your coupling’s lubrication is not sufficient, it may lead to hardening and cracking. In addition, it’s possible to develop leaks that could cause damage.

Modifications

The aim of this paper is to investigate the effects of coupling modifications. It shows that such modifications can adversely affect the performance of the coupling mechanism. Moreover, the modifications can be predicted using chemical physics methods. The results presented here are not exhaustive and further research is needed to understand the effects of such coupling modifications.

The modifications to coupling involve nonlinear structural modifications. Four examples of such modifications are presented. Each is illustrated with example applications. Then, the results are verified through experimental and simulated case studies. The proposed methods are applicable to large and complex structures. They are applicable to a variety of engineering systems, including nonlinear systems.

editor by CX 2023-05-24

China Sullair 2250152-670 Screw Air Compressor Spare Parts Rubber Coupling Element coupling adapter

Item Description

Sullair 2250152-670 Screw Air Compressor Spare Components Rubber Coupling Component

The minimal strain valve is composed of valve entire body, valve core, spring, sealing ring, modifying screw, and many others. It is put in at the outlet of the oil separator. Its purpose is to maintain the pressure in the oil separation tank from slipping beneath .4MPa. The compressed air that contains oil can be divided greater in the separator and the reduction of lubricating oil can be reduced. At the same time, it can guarantee the gasoline pressure required to establish the oil force. The minimum force valve also functions as a a single-way valve to prevent the compressed air in the method from flowing back when the technique is shut down. The keeping pressure of the minimal stress valve has been altered prior to leaving the manufacturing facility. If the holding strain alterations owing to a prolonged time of use, it can be modified by the adjustment screw on the valve.

Function

- Immediate Replace CZPT & Product Compatibility one

1613950300 1622365200 1622365600 Atlas Copco GA75 Air filter 1619279800 Atlas Copco GA250 Air filter Atlas Copco GA220 Air filter 1627009499 Atlas Copco GA30 Air filter 1613740700 Atlas Copco GA37 Air filter 1613740800 Atlas Copco GA75 Air filter 1613800400 Atlas Copco GA55 Air filter 1613955710 Atlas Copco GA55 Air filter 1613950300 Atlas Copco GA11, GA22 Air filter 1613872000 Atlas Copco GA18 Air filter 1619126900 Atlas Copco Air filter 157117000 Atlas Copco GA90C/one hundred ten/132/one hundred sixty Air filter 1621054799 Atlas Copco Air filter 1613950300 Atlas Copco Air filter 1621510700 Atlas Copco XRHS396. XRHS366, XRVS455 Air filter 2914501700 Atlas Copco XRHS396. XRHS366, XRVS455 Air filter CF810 Atlas Copco Air filter 1619162900 Atlas Copco Air filter 1619284700 Atlas Copco Air filter Atlas Copco Air filter 1621574300 Atlas Copco XA75 Separator 1614437300 Atlas Copco Separator 290157101 Atlas Copco GA30 Separator 162205710 Atlas Copco Separator 2957106100 Atlas Copco XRVS10 Separator 165712880 Atlas Copco Separator 2957100401 Atlas Copco GA11C-GA30C Separator 290157100 Atlas Copco GA22 Separator 1613755710 Atlas Copco Separator 1622646000 Atlas Copco Separator 2957134301 Atlas Copco Separator 1613688002 Atlas Copco Separator 1613692100 Atlas Copco GA250 Separator 1621938600 Atlas Copco GA18 Separator 1612386900 Atlas Copco GA45 Separator 1613839700 Atlas Copco GA45,GA30 Separator 1613688000 Atlas Copco Separator 1613901400 Atlas Copco Separator 1257172200 Atlas Copco GA37 Separator 1613243300 Atlas Copco Separator 1616465602 Atlas Copco GA75 Separator 1613730600 Atlas Copco GA75,GA55 Separator 1613955900 Atlas Copco GA75VSD Separator 2957185800 Atlas Copco Separator 290657100 Atlas Copco Separator 2957156602 Atlas Copco GA90 Separator 1622365600 Atlas Copco GA75 Separator 1613800700 Atlas Copco GA1110 Separator 2252631300 Atlas Copco Separator 2906056500 Atlas Copco GA110 Separator 1614905400 Atlas Copco GA200 / GA250 Separator 1614952100 Atlas Copco GA132/a hundred and sixty Separator 1614905600 Atlas Copco Separator 162257100 Atlas Copco Separator 15130 0571 Atlas Copco Separator 1621938500 Atlas Copco GA90C Separator 1614642300 Atlas Copco Separator 2957107800 Atlas Copco Separator 2957177400 Atlas Copco Separator 1614704800 Atlas Copco Separator 162257100 Atlas Copco Air filter 1621054700 Atlas Copco GA37 Separator 1613839702 Atlas Copco Separator 2957153600 Atlas Copco GA90 Separator 1621938400 Atlas Copco Separator 2957153700 Atlas Copco Separator 162205711 Atlas Copco Separator 1613610590 Atlas Copco Separator 2911001700 Atlas Copco Separator 1257141900 Atlas Copco Separator 1621574200 Atlas Copco Separator 2901162600 Atlas Copco GA37 Separator 1622314000 Atlas Copco GA5-GA11 Separator 2957152300 Atlas Copco Air filter 1622185501 Atlas Copco GA132 Separator 1621938599 Atlas Copco GA75-8 Separator 1622569300 Atlas Copco Separator 1612386901 Atlas Copco Separator 1616465600 Atlas Copco Separator 1257134300 Atlas Copco Separator 1614905499 Atlas Copco Separator 1616283600 Atlas Copco Separator 1615594800 Atlas Copco Separator 22526313 Atlas Copco Separator 1613765710 Atlas Copco GA11 Oil filter 1613610500 Atlas Copco Oil filter 1614874700 Atlas Copco Oil filter 1625165601 Atlas Copco Oil filter 1513033700 Atlas Copco Oil filter 1257104090 Atlas Copco Oil filter 1625165602 Atlas Copco GA37VSD Oil filter 1622314200 Atlas Copco GA75VSD Oil filter 1622365200 Atlas Copco GA30/37 (Old) Separator 1202641400 Atlas Copco Air filter 161395710 Atlas Copco GA237 Separator 1614532900 Atlas Copco Oil filter 1257104000 Atlas Copco Oil filter 1621875000 Atlas Copco Oil filter 1513033701 Atlas Copco Oil filter 1614874799 Atlas Copco Separator 16219 0571 Atlas Copco Separator 2957100300

/ Piece

|1 Piece

(Min. Order)

###

Customized: Customized Standard Component: Standard Component Material: Stainless Steel Category: Solenoid Valve Cooling System: Air Cooling Cylinder Position: Vertical ###

Customization: ###

Part No. Part No. Part No. Part No. 1092200288 1621737800 1513033790 1622365200 1202804002 1622783600 1613610500 1625752500 1513033700 1625480000 1613610590 1625775400 1613610500 1625752500 1614874700 2202929400 1613737800 WD962 1622035101 16227836000 1614727300 WD1374 1622087100 1621737800 1614874700 1622365200 1622314200 1622314200 1619262700 1202804002 1622314280 1622314280 ###

Air Compressor Models Air Filter Oil Filter Separator GA 55 PL 1613950300 1622365200 1622365600 GA 75 PL 1613950300 1622460100 1622365600 GA 75 VSD 1613950300 1622365200 2901085800 GA 90 from 2005 1613950300 1622365200 1622365600 GA 75 VSD from 2006/07 1613950300 1622365200 1622365600 GA 90 VSD from 2006/07 1613950300 1622460100 1622365600 GA 90 from s/n API 610000 1613950300 1622365200 1622365600 Atlas Copco GA75 Air filter 1619279800 Atlas Copco GA250 Air filter 1621054600 Atlas Copco GA220 Air filter 1627009499 Atlas Copco GA30 Air filter 1613740700 Atlas Copco GA37 Air filter 1613740800 Atlas Copco GA75 Air filter 1613800400 Atlas Copco GA55 Air filter 1613950100 Atlas Copco GA55 Air filter 1613950300 Atlas Copco GA11, GA22 Air filter 1613872000 Atlas Copco GA18 Air filter 1619126900 Atlas Copco Air filter 1030107000 Atlas Copco GA90C/110/132/160 Air filter 1621054799 Atlas Copco Air filter 1613950300 Atlas Copco Air filter 1621510700 Atlas Copco XRHS396. XRHS366, XRVS455 Air filter 2914501700 Atlas Copco XRHS396. XRHS366, XRVS455 Air filter CF810 Atlas Copco Air filter 1619162900 Atlas Copco Air filter 1619284700 Atlas Copco Air filter 1621054600 Atlas Copco Air filter 1621574300 Atlas Copco XA75 Separator 1614437300 Atlas Copco Separator 2901077901 Atlas Copco GA30 Separator 1622007900 Atlas Copco Separator 2901006100 Atlas Copco XRVS10 Separator 1604132880 Atlas Copco Separator 2901000401 Atlas Copco GA11C-GA30C Separator 2901077900 Atlas Copco GA22 Separator 1613750200 Atlas Copco Separator 1622646000 Atlas Copco Separator 2901034301 Atlas Copco Separator 1613688002 Atlas Copco Separator 1613692100 Atlas Copco GA250 Separator 1621938600 Atlas Copco GA18 Separator 1612386900 Atlas Copco GA45 Separator 1613839700 Atlas Copco GA45,GA30 Separator 1613688000 Atlas Copco Separator 1613901400 Atlas Copco Separator 1202872200 Atlas Copco GA37 Separator 1613243300 Atlas Copco Separator 1616465602 Atlas Copco GA75 Separator 1613730600 Atlas Copco GA75,GA55 Separator 1613955900 Atlas Copco GA75VSD Separator 2901085800 Atlas Copco Separator 2906075200 Atlas Copco Separator 2901056602 Atlas Copco GA90 Separator 1622365600 Atlas Copco GA75 Separator 1613800700 Atlas Copco GA1110 Separator 2252631300 Atlas Copco Separator 2906056500 Atlas Copco GA110 Separator 1614905400 Atlas Copco GA200 / GA250 Separator 1614952100 Atlas Copco GA132/160 Separator 1614905600 Atlas Copco Separator 1622051600 Atlas Copco Separator 1513005800 Atlas Copco Separator 1621938500 Atlas Copco GA90C Separator 1614642300 Atlas Copco Separator 2901007800 Atlas Copco Separator 2901077400 Atlas Copco Separator 1614704800 Atlas Copco Separator 1622087100 Atlas Copco Air filter 1621054700 Atlas Copco GA37 Separator 1613839702 Atlas Copco Separator 2901053600 Atlas Copco GA90 Separator 1621938400 Atlas Copco Separator 2901053700 Atlas Copco Separator 1622007901 Atlas Copco Separator 1613610590 Atlas Copco Separator 2911001700 Atlas Copco Separator 1202741900 Atlas Copco Separator 1621574200 Atlas Copco Separator 2901162600 Atlas Copco GA37 Separator 1622314000 Atlas Copco GA5-GA11 Separator 2901052300 Atlas Copco Air filter 1622185501 Atlas Copco GA132 Separator 1621938599 Atlas Copco GA75-8 Separator 1622569300 Atlas Copco Separator 1612386901 Atlas Copco Separator 1616465600 Atlas Copco Separator 1202834300 Atlas Copco Separator 1614905499 Atlas Copco Separator 1616283600 Atlas Copco Separator 1615594800 Atlas Copco Separator 22526313 Atlas Copco Separator 1613760200 Atlas Copco GA11 Oil filter 1613610500 Atlas Copco Oil filter 1614874700 Atlas Copco Oil filter 1625165601 Atlas Copco Oil filter 1513033700 Atlas Copco Oil filter 1202804090 Atlas Copco Oil filter 1625165602 Atlas Copco GA37VSD Oil filter 1622314200 Atlas Copco GA75VSD Oil filter 1622365200 Atlas Copco GA30/37 (OLD) Separator 1202641400 Atlas Copco Air filter 1613900100 Atlas Copco GA237 Separator 1614532900 Atlas Copco Oil filter 1202804000 Atlas Copco Oil filter 1621875000 Atlas Copco Oil filter 1513033701 Atlas Copco Oil filter 1614874799 Atlas Copco Separator 1621907700 Atlas Copco Separator 2901000300

/ Piece

|1 Piece

(Min. Order)

###

Customized: Customized Standard Component: Standard Component Material: Stainless Steel Category: Solenoid Valve Cooling System: Air Cooling Cylinder Position: Vertical ###

Customization: ###

Part No. Part No. Part No. Part No. 1092200288 1621737800 1513033790 1622365200 1202804002 1622783600 1613610500 1625752500 1513033700 1625480000 1613610590 1625775400 1613610500 1625752500 1614874700 2202929400 1613737800 WD962 1622035101 16227836000 1614727300 WD1374 1622087100 1621737800 1614874700 1622365200 1622314200 1622314200 1619262700 1202804002 1622314280 1622314280 ###

Air Compressor Models Air Filter Oil Filter Separator GA 55 PL 1613950300 1622365200 1622365600 GA 75 PL 1613950300 1622460100 1622365600 GA 75 VSD 1613950300 1622365200 2901085800 GA 90 from 2005 1613950300 1622365200 1622365600 GA 75 VSD from 2006/07 1613950300 1622365200 1622365600 GA 90 VSD from 2006/07 1613950300 1622460100 1622365600 GA 90 from s/n API 610000 1613950300 1622365200 1622365600 Atlas Copco GA75 Air filter 1619279800 Atlas Copco GA250 Air filter 1621054600 Atlas Copco GA220 Air filter 1627009499 Atlas Copco GA30 Air filter 1613740700 Atlas Copco GA37 Air filter 1613740800 Atlas Copco GA75 Air filter 1613800400 Atlas Copco GA55 Air filter 1613950100 Atlas Copco GA55 Air filter 1613950300 Atlas Copco GA11, GA22 Air filter 1613872000 Atlas Copco GA18 Air filter 1619126900 Atlas Copco Air filter 1030107000 Atlas Copco GA90C/110/132/160 Air filter 1621054799 Atlas Copco Air filter 1613950300 Atlas Copco Air filter 1621510700 Atlas Copco XRHS396. XRHS366, XRVS455 Air filter 2914501700 Atlas Copco XRHS396. XRHS366, XRVS455 Air filter CF810 Atlas Copco Air filter 1619162900 Atlas Copco Air filter 1619284700 Atlas Copco Air filter 1621054600 Atlas Copco Air filter 1621574300 Atlas Copco XA75 Separator 1614437300 Atlas Copco Separator 2901077901 Atlas Copco GA30 Separator 1622007900 Atlas Copco Separator 2901006100 Atlas Copco XRVS10 Separator 1604132880 Atlas Copco Separator 2901000401 Atlas Copco GA11C-GA30C Separator 2901077900 Atlas Copco GA22 Separator 1613750200 Atlas Copco Separator 1622646000 Atlas Copco Separator 2901034301 Atlas Copco Separator 1613688002 Atlas Copco Separator 1613692100 Atlas Copco GA250 Separator 1621938600 Atlas Copco GA18 Separator 1612386900 Atlas Copco GA45 Separator 1613839700 Atlas Copco GA45,GA30 Separator 1613688000 Atlas Copco Separator 1613901400 Atlas Copco Separator 1202872200 Atlas Copco GA37 Separator 1613243300 Atlas Copco Separator 1616465602 Atlas Copco GA75 Separator 1613730600 Atlas Copco GA75,GA55 Separator 1613955900 Atlas Copco GA75VSD Separator 2901085800 Atlas Copco Separator 2906075200 Atlas Copco Separator 2901056602 Atlas Copco GA90 Separator 1622365600 Atlas Copco GA75 Separator 1613800700 Atlas Copco GA1110 Separator 2252631300 Atlas Copco Separator 2906056500 Atlas Copco GA110 Separator 1614905400 Atlas Copco GA200 / GA250 Separator 1614952100 Atlas Copco GA132/160 Separator 1614905600 Atlas Copco Separator 1622051600 Atlas Copco Separator 1513005800 Atlas Copco Separator 1621938500 Atlas Copco GA90C Separator 1614642300 Atlas Copco Separator 2901007800 Atlas Copco Separator 2901077400 Atlas Copco Separator 1614704800 Atlas Copco Separator 1622087100 Atlas Copco Air filter 1621054700 Atlas Copco GA37 Separator 1613839702 Atlas Copco Separator 2901053600 Atlas Copco GA90 Separator 1621938400 Atlas Copco Separator 2901053700 Atlas Copco Separator 1622007901 Atlas Copco Separator 1613610590 Atlas Copco Separator 2911001700 Atlas Copco Separator 1202741900 Atlas Copco Separator 1621574200 Atlas Copco Separator 2901162600 Atlas Copco GA37 Separator 1622314000 Atlas Copco GA5-GA11 Separator 2901052300 Atlas Copco Air filter 1622185501 Atlas Copco GA132 Separator 1621938599 Atlas Copco GA75-8 Separator 1622569300 Atlas Copco Separator 1612386901 Atlas Copco Separator 1616465600 Atlas Copco Separator 1202834300 Atlas Copco Separator 1614905499 Atlas Copco Separator 1616283600 Atlas Copco Separator 1615594800 Atlas Copco Separator 22526313 Atlas Copco Separator 1613760200 Atlas Copco GA11 Oil filter 1613610500 Atlas Copco Oil filter 1614874700 Atlas Copco Oil filter 1625165601 Atlas Copco Oil filter 1513033700 Atlas Copco Oil filter 1202804090 Atlas Copco Oil filter 1625165602 Atlas Copco GA37VSD Oil filter 1622314200 Atlas Copco GA75VSD Oil filter 1622365200 Atlas Copco GA30/37 (OLD) Separator 1202641400 Atlas Copco Air filter 1613900100 Atlas Copco GA237 Separator 1614532900 Atlas Copco Oil filter 1202804000 Atlas Copco Oil filter 1621875000 Atlas Copco Oil filter 1513033701 Atlas Copco Oil filter 1614874799 Atlas Copco Separator 1621907700 Atlas Copco Separator 2901000300 What Is a Coupling?

A coupling is a mechanical device that links two shafts together and transmits power. Its purpose is to join rotating equipment while permitting a small amount of misalignment or end movement. Couplings come in a variety of different types and are used in a variety of applications. They can be used in hydraulics, pneumatics, and many other industries.

Types

Coupling is a term used to describe a relationship between different modules. When a module depends on another, it can have different types of coupling. Common coupling occurs when modules share certain overall constraints. When this type of coupling occurs, any changes to the common constraint will also affect the other modules. Common coupling has its advantages and disadvantages. It is difficult to maintain and provides less control over the modules than other types of coupling.

There are many types of coupling, including meshing tooth couplings, pin and bush couplings, and spline couplings. It is important to choose the right coupling type for your specific application to get maximum uptime and long-term reliability. Listed below are the differences between these coupling types.

Rigid couplings have no flexibility, and require good alignment of the shafts and support bearings. They are often used in applications where high torque is required, such as in push-pull machines. These couplings are also useful in applications where the shafts are firmly attached to one another.

Another type of coupling is the split muff coupling. This type is made of cast iron and has two threaded holes. The coupling halves are attached with bolts or studs.

Applications

The coupling function is an incredibly versatile mathematical tool that can be used in many different scientific domains. These applications range from physics and mathematics to biology, chemistry, cardio-respiratory physiology, climate science, and electrical engineering. The coupling function can also help to predict the transition from one state to another, as well as describing the functional contributions of subsystems in the system. In some cases, it can even be used to reveal the mechanisms that underlie the functionality of interactions.

The coupling selection process begins with considering the intended use of the coupling. The application parameters must be determined, as well as the operating conditions. For example, if the coupling is required to be used for power transmission, the design engineer should consider how easily the coupling can be installed and serviced. This step is vital because improper installation can result in a more severe misalignment than is specified. Additionally, the coupling must be inspected regularly to ensure that the design parameters remain consistent and that no detrimental factors develop.

Choosing the right coupling for your application is an important process, but it need not be difficult. To find the right coupling, you must consider the type of machine and environment, as well as the torque, rpm, and inertia of the system. By answering these questions, you will be able to select the best coupling for your specific application.

Problems

A coupling is a device that connects two rotating shafts to transfer torque and rotary motion. To achieve optimal performance, a coupling must be designed for the application requirements it serves. These requirements include service, environmental, and use parameters. Otherwise, it can prematurely fail, causing inconvenience and financial loss.

In order to prevent premature failure, couplings should be properly installed and maintained. A good practice is to refer to the specifications provided by the manufacturer. Moreover, it is important to perform periodic tests to evaluate the effectiveness of the coupling. The testing of couplings should be performed by qualified personnel.

editor by CX 2023-03-30

China FCL Flexible Shaft Couplings for Gearbox and Motor Screw Coupling Transmission Shaft Coupling for Spinning and Weaving Machines manufacturer

Merchandise Description

FCL Adaptable Shaft Couplings for Gearbox and Motor Screw Coupling Transmission Shaft Coupling for Spinning and Weaving Equipment

Characteristics

- Compact developing, effortless set up.

- Practical maintenance, small dimension, and lightweight.

- Commonly utilized in medium and small energy transmission techniques pushed by motors, this kind of as speed reducers, hoists, compressors, conveyors, sp

Item Description

| Measurement | N.m | r/min |

D | D1 | d1 | L | C | n-M | kg | |

| FCL90 | 4 | 4000 | ninety | 35.five | eleven | 28 | three | four-M8 | one.7 | |

| FCL100 | ten | 4000 | 100 | 40 | 11 | 35.five | three | 4-M10 | 2.3 | |

| FCL112 | 16 | 4000 | 112 | 45 | 13 | forty | three | four-M10 | two.8 | |

| FCL125 | 25 | 4000 | a hundred twenty five | sixty five | fifty | thirteen | forty five | 3 | 4-M12 | 4 |

| FCL140 | fifty | 4000 | a hundred and forty | seventy one | sixty three | 13 | fifty | three | six-M12 | 5.four |

| FCL160 | 110 | 4000 | 160 | 80 | 15 | fifty six | three | 8-M12 | eight | |

| FCL180 | 157 | 3500 | 180 | 90 | 15 | sixty three | 3 | 8-M12 | 10.5 | |

| FCL200 | 245 | 3200 | 200 | 100 | 21 | 71 | 4 | eight-M20 | 16.2 | |

| FCL224 | 392 | 2850 | 224 | 112 | 21 | eighty | 4 | eight-M20 | 21.three | |

| FCL250 | 618 | 2550 | 250 | 125 | twenty five | ninety | four | 8-M24 | 31.six | |