FCL 1/8822 0571 -57152031 Fax: 86~/8822 0571 -57152030

Http://kasinchain

| Standard Or Nonstandard: |

Standard |

| Shaft Hole: |

19-32 |

| Torque: |

>80N.M |

| Bore Diameter: |

85mm |

| Speed: |

4000r/M |

| Structure: |

Flexible |

| Samples: |

US$ 12/Set

1 Set(Min.Order)

|

Request Sample

|

| Customization: |

Available

|

Customized Request

|

Can Pin Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, pin couplings can be used in both horizontal and vertical shaft arrangements. These couplings are designed to accommodate angular misalignment, parallel misalignment, and axial movement, making them versatile for various shaft orientations.

In horizontal shaft arrangements, where the shafts are aligned on the same horizontal plane, pin couplings can efficiently transmit torque while allowing for flexibility to accommodate minor misalignments and shaft movements. The pins and flexible elements in the coupling enable angular displacement and radial flexibility, ensuring smooth power transmission even if the shafts are not perfectly aligned.

In vertical shaft arrangements, where the shafts are aligned on a vertical plane, pin couplings can also be used effectively. The coupling design allows for axial movement, which is crucial in vertical applications where the shafts may experience expansion or contraction due to thermal changes or other factors. The flexible nature of pin couplings allows them to handle these axial movements without compromising the coupling’s performance.

Whether in horizontal or vertical arrangements, pin couplings are commonly used in various industrial applications, including pumps, compressors, conveyors, and other rotating machinery. They are known for their simplicity, ease of installation, and ability to provide reliable power transmission while accommodating misalignment and shaft movement.

When using pin couplings in either arrangement, it is essential to ensure proper alignment and regular maintenance to maximize their performance and service life. Additionally, considering factors like torque requirements, operating conditions, and environmental considerations will help in selecting the appropriate pin coupling for a specific application.

What Industries Commonly Use Pin Couplings for Power Transmission?

Pin couplings are widely used in various industries for power transmission due to their ability to accommodate misalignment and provide reliable torque transmission. Some of the industries where pin couplings are commonly employed include:

- 1. Manufacturing: In manufacturing processes, pin couplings are used in conveyor systems, mixers, agitators, and other machinery to transfer power between motors and driven equipment.

- 2. Pulp and Paper: The pulp and paper industry uses pin couplings in machinery such as pumps, fans, and rotary kilns for continuous power transmission.

- 3. Chemical and Petrochemical: Pin couplings find applications in chemical processing plants, refineries, and petrochemical facilities for various rotating equipment.

- 4. Water and Wastewater: Pin couplings are used in water treatment facilities, pumps, and blowers to transfer power efficiently.

- 5. Steel and Metal Processing: Steel mills and metal processing plants utilize pin couplings in rolling mills, extruders, and other equipment.

- 6. Food and Beverage: Pin couplings are employed in food processing machinery, packaging equipment, and conveyor systems.

- 7. Mining and Quarrying: The mining industry uses pin couplings in crushers, conveyor belts, and various mineral processing equipment.

- 8. Oil and Gas: Pin couplings are used in the oil and gas sector for pumps, compressors, and drilling equipment.

- 9. Power Generation: In power plants, pin couplings are used in turbines, generators, and other power transmission systems.

- 10. Construction and Heavy Equipment: Pin couplings find applications in construction machinery, earthmoving equipment, and other heavy-duty machinery.

- 11. Agriculture: In agricultural machinery, pin couplings are used in tractors, irrigation systems, and grain processing equipment.

These are just some examples of the industries where pin couplings are commonly used. Pin couplings offer versatility, ease of installation, and reliability, making them suitable for a wide range of applications in different sectors where power transmission is essential.

Selecting the Appropriate Pin Coupling for a Specific Application

Choosing the right pin coupling for a specific application involves considering several factors to ensure optimal performance, reliability, and safety. Here are the key steps to select the appropriate pin coupling:

- 1. Determine the Application Requirements: Understand the specific requirements of the application, including torque and speed specifications, shaft sizes, and misalignment tolerances. Consider the operating conditions, such as temperature, humidity, and exposure to corrosive substances.

- 2. Calculate Torque and Power: Calculate the torque and power requirements of the application to determine the appropriate pin coupling’s torque capacity. Make sure to consider both steady-state and peak torque loads.

- 3. Consider Misalignment Tolerance: Evaluate the degree of misalignment expected in the system. Different pin coupling designs offer varying levels of misalignment tolerance. Choose a coupling that can accommodate the expected misalignment without compromising performance.

- 4. Select the Pin Coupling Type: Based on the application requirements, choose the appropriate pin coupling type – single pin, double pin, triangular pin, splined pin, or taper pin coupling. Each type offers different torque capacities and misalignment capabilities.

- 5. Check Material and Construction: Consider the materials used in the pin coupling’s construction. Common materials include steel, stainless steel, and alloy materials. The material should be suitable for the application’s environmental conditions and corrosion resistance.

- 6. Verify Safety Features: Ensure the selected pin coupling has safety features, such as a fail-safe mechanism to protect equipment from overload or shock loads. Safety is crucial to prevent damage to machinery and ensure operator protection.

- 7. Consult with Manufacturers or Engineers: If unsure about the best pin coupling for the application, consult with coupling manufacturers or mechanical engineers. They can provide valuable insights and recommendations based on their expertise.

By following these steps, you can select the appropriate pin coupling that matches the specific needs of the application, providing reliable and efficient power transmission while minimizing the risk of downtime and equipment failure.

editor by CX 2023-10-07

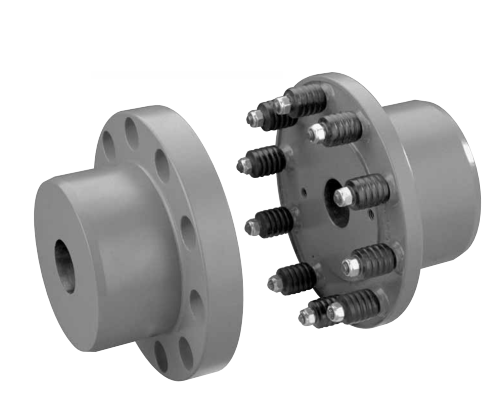

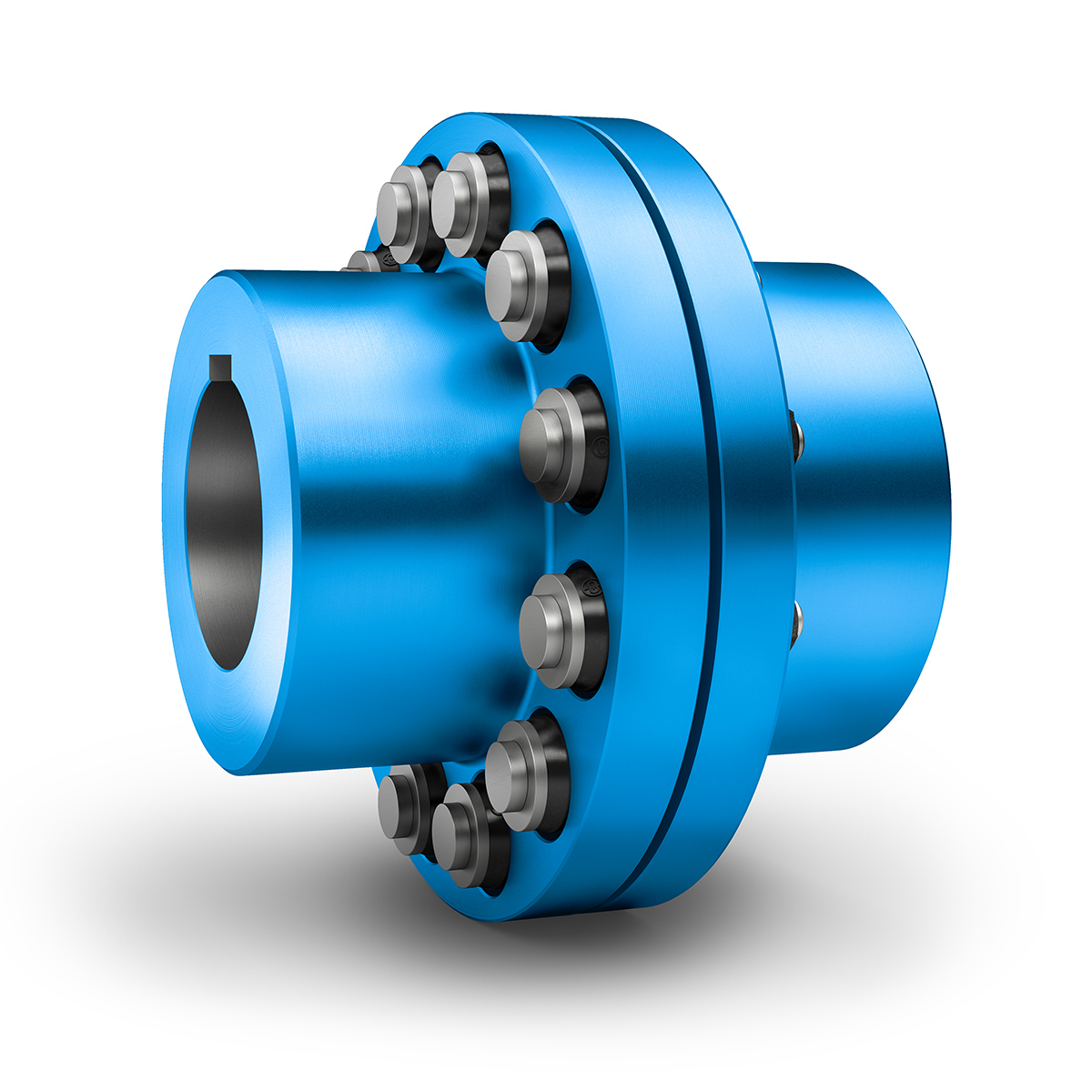

Product Description

Product Description

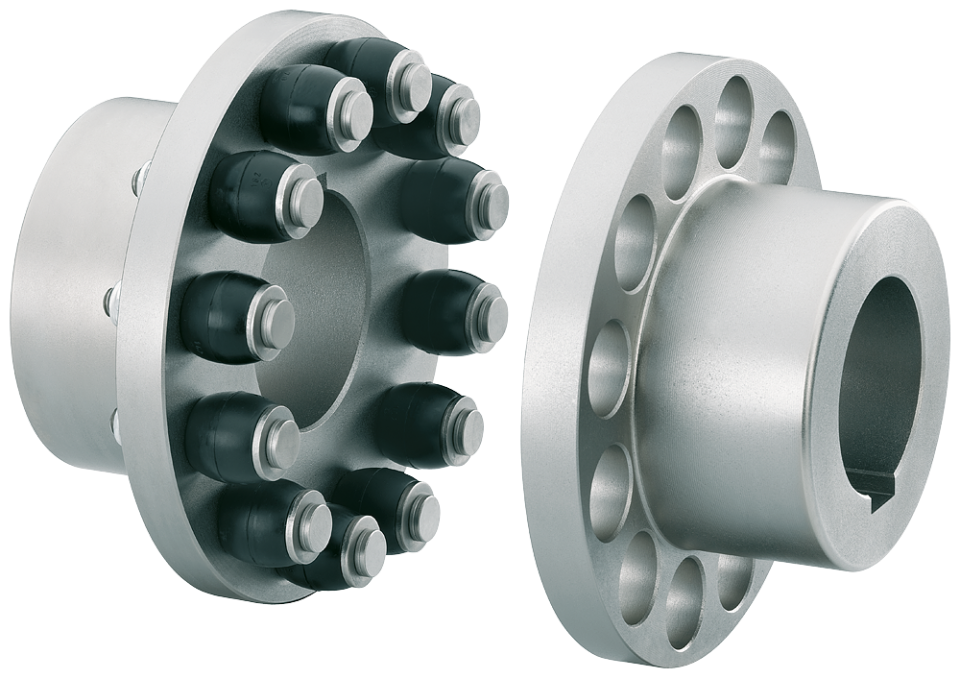

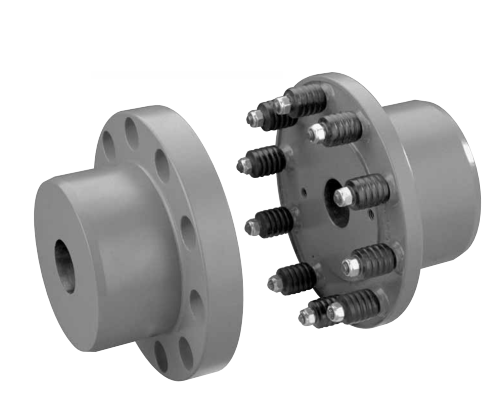

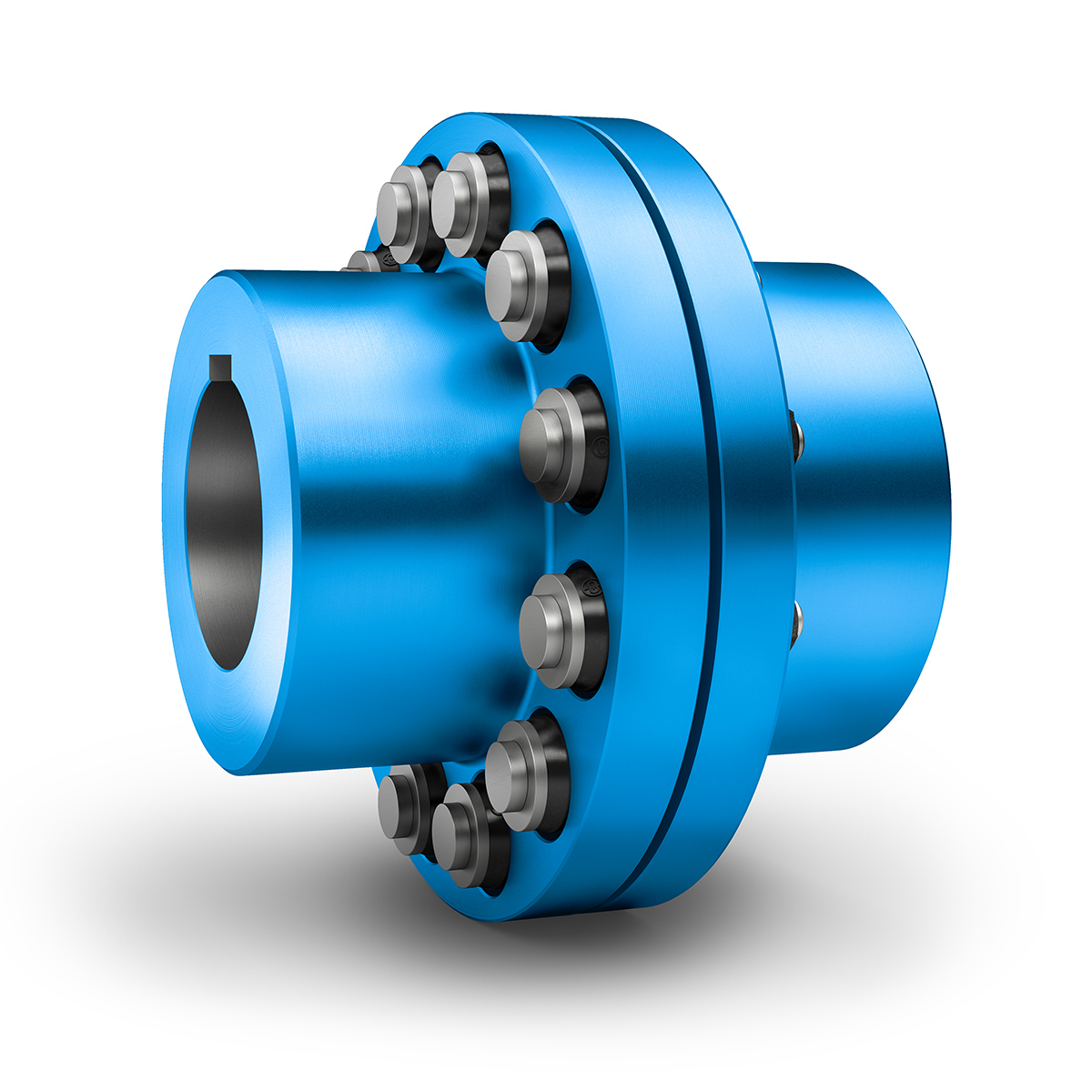

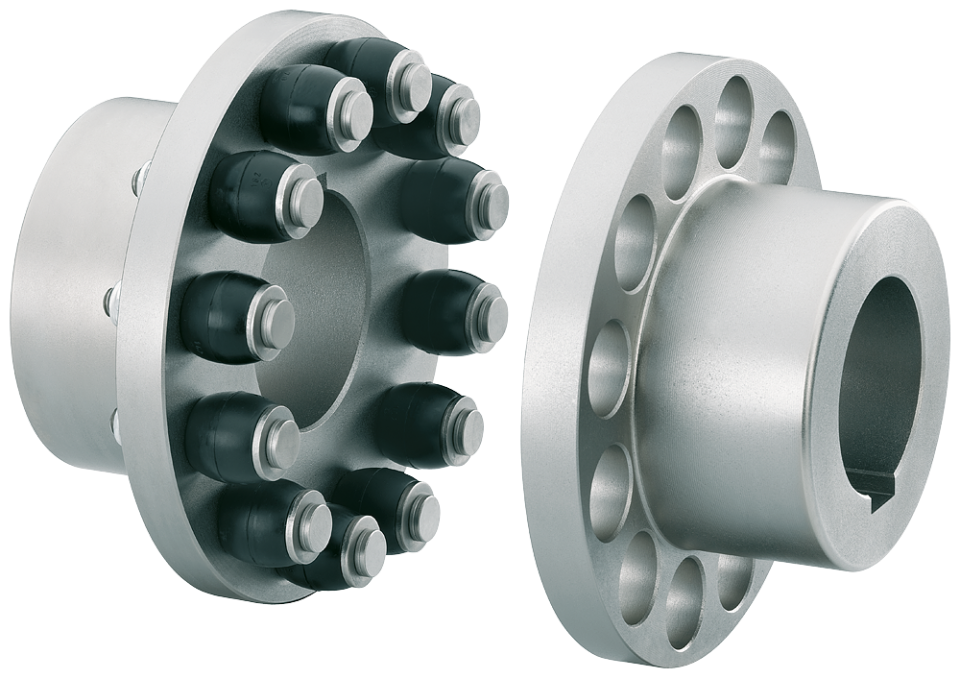

FCL Coupling/Shaft Coupling /Pin & Bush Coupling /FCL Flexible Coupling/NBK FCL Coupling is widely used for its compacts designing, easy installation, convenient maintenance, small and light weight.

As long as the relative displacement between shafts is kept within the specified tolerance, couplings will operate the best function and have a longer working life.

Thus it is greatly demanded in medium and minor power transmission systems driven by motors, such as speed reducers, hoists, compressors, conveyors, spinning and weaving machines and ball mills.

Technical Date

| KASIN No. |

A |

d |

L |

C1 |

C2 |

B |

F1 |

F2 |

n |

a |

M |

t |

Parts No. |

Max. Torque |

Max.R.P.M |

Eccentricity |

Angularity |

End-Play |

| FCL 1/8822 0571 -57152031 Fax: 86~/8822 0571 -57152030

Http://kasinchain

| Standard Or Nonstandard: |

Standard |

| Shaft Hole: |

19-32 |

| Torque: |

30-50N.M |

| Bore Diameter: |

75mm |

| Speed: |

4000r/M |

| Structure: |

Flexible |

| Samples: |

US$ 9/Set

1 Set(Min.Order)

|

Request Sample

|

| Customization: |

Available

|

Customized Request

|

How Does a Pin Coupling Protect Connected Equipment from Shock Loads and Vibrations?

Pin couplings are designed to provide excellent protection to connected equipment from shock loads and vibrations, ensuring the smooth and reliable operation of the machinery. The unique features of pin couplings contribute to their ability to absorb and dampen shock loads and vibrations effectively:

- Flexibility: Pin couplings possess a certain degree of flexibility due to the presence of movable pins. When subjected to sudden shock loads or vibrations, the pins can flex and move slightly, absorbing the impact and preventing it from transmitting directly to the connected equipment. This flexibility helps in reducing stress and minimizing the risk of damage to the machinery.

- Torsional Compliance: The pin coupling’s design allows for a certain amount of torsional compliance. This means that when the connected shafts experience slight misalignments or angular displacements, the pin coupling can compensate for these variations without causing additional stress or vibration in the system. This feature ensures that the machinery remains in proper alignment even under dynamic conditions, reducing wear and tear.

- Damping Characteristics: The presence of movable pins introduces damping characteristics to the coupling. When vibrations occur in the system, the pins can dampen these oscillations, preventing resonance and the amplification of vibrations. This damping effect improves the overall stability and performance of the machinery.

- Strength and Resilience: High-quality pin couplings are constructed from durable materials with excellent fatigue resistance. This enables the coupling to withstand repeated shock loads and vibrations over an extended period without compromising its integrity. The strength and resilience of the pin coupling contribute to the protection of the connected equipment.

Overall, pin couplings are reliable and versatile components that can effectively protect connected equipment from shock loads and vibrations. Their flexibility, torsional compliance, damping characteristics, and robust construction make them suitable for various industrial applications where shock and vibration mitigation are essential for maintaining the health and longevity of machinery and equipment.

Factors to Consider When Choosing a Pin Coupling for a Specific System

When selecting a pin coupling for a specific system, several critical factors need to be considered to ensure optimal performance, reliability, and longevity. Each application has unique requirements, and choosing the right pin coupling involves assessing the following factors:

1. Torque and Power Requirements: Determine the torque and power transmission requirements of the system. The pin coupling must be capable of handling the maximum torque and power generated by the connected equipment.

2. Operating Speed: Consider the rotational speed of the system’s driving and driven shafts. The pin coupling’s design should allow for smooth and efficient operation at the specified speed range.

3. Misalignment Tolerance: Assess the degree of misalignment between the shafts that the coupling needs to accommodate. Pin couplings are suitable for applications with moderate angular, parallel, and axial misalignment.

4. Operating Environment: Consider the environmental conditions the coupling will be exposed to, including temperature, humidity, dust, and presence of corrosive substances. Choose a pin coupling with materials and surface treatments suitable for the operating environment.

5. Size and Space Constraints: Ensure that the selected pin coupling fits within the available space and does not interfere with other components in the system.

6. Serviceability and Maintenance: Evaluate the ease of installation, maintenance, and replacement of the pin coupling. Easy-to-service couplings can help reduce downtime and maintenance costs.

7. Shock and Vibration: Consider the level of shock and vibration the system will experience. The pin coupling should be robust enough to handle these dynamic loads without failure.

8. Cost: Evaluate the overall cost of the pin coupling, including its initial purchase price, maintenance costs, and potential downtime expenses. Choose a coupling that offers the best balance of performance and cost-effectiveness.

9. Material Selection: Select the appropriate materials for the pin coupling based on the application requirements. Common materials include carbon steel, stainless steel, and alloy steel.

10. Compatibility: Ensure that the pin coupling is compatible with the specific shaft sizes and configurations of the system’s driving and driven components.

11. Compliance with Industry Standards: Check if the pin coupling meets relevant industry standards and safety requirements.

By carefully considering these factors, engineers and system designers can choose the most suitable pin coupling for their specific application. It’s essential to work closely with coupling manufacturers or suppliers to ensure that the selected coupling meets all the necessary specifications and requirements.

Types of Pin Coupling Designs

Pin couplings, also known as shear pin couplings, come in various designs to suit different application requirements. The main types of pin coupling designs are as follows:

- 1. Single Pin Coupling: In this design, a single shear pin is used to connect the two shafts. The pin is placed in a hole that runs through both coupling halves. Under excessive torque or shock loads, the pin shears off, disconnecting the shafts and protecting the equipment from damage. Single pin couplings are commonly used in light to moderate-duty applications.

- 2. Double Pin Coupling: Double pin couplings use two shear pins that are positioned 180 degrees apart. This design provides increased torque capacity and improved balance compared to the single pin design. Double pin couplings are suitable for applications with higher torque requirements.

- 3. Triangular Pin Coupling: Triangular pin couplings use three pins arranged in a triangular pattern around the circumference of the coupling. This design offers even higher torque capacity and improved torsional stiffness. Triangular pin couplings are ideal for heavy-duty applications where higher torque and misalignment tolerance are essential.

- 4. Splined Pin Coupling: Splined pin couplings use splines instead of solid pins to transmit torque between the shafts. The splines provide a more secure connection and better torque transmission compared to solid pins. Splined pin couplings are commonly used in precision motion control applications.

- 5. Taper Pin Coupling: Taper pin couplings use tapered pins that wedge tightly into matching tapered holes in the coupling halves. This design offers excellent torque transmission and alignment capabilities. Taper pin couplings are often used in heavy machinery and power transmission systems.

Each type of pin coupling design has its advantages and limitations, and the selection depends on factors such as the application’s torque requirements, misalignment tolerance, and environmental conditions. It is essential to choose the right type of pin coupling to ensure optimal performance, reliability, and safety in the mechanical system.

editor by CX 2023-09-08

| |