Product Description

Product Description

This product contains Full set, Female set, Male set, Brass nut. With years’ experience on coupling products, PLENT emphasis its working center to on product quality control and professional aftersales service.

Product Parameters

| Size | Thread | Part# | Material |

| 1″ | NPS | TXPL100-AL | Aluminum body with brass nut |

| 1-1/4″ | NPS | TXPL125-AL | |

| 1-1/2″ | NPS | TXPL150-AL | |

| 2″ | NPS | TXPL200-AL | |

| 2-1/2″ | NPS | TXPL250-AL | |

| 3″ | NPS | TXPL300-AL | |

| 4″ | NPS | TXPL400-AL | |

| 6″ | NPS | TXPL600-AL |

Our Advantages

* Economic (durable product life decrease resource waste)

* Safety Sealing (reliable sealing material)

* Professional aftersales service (Experienced technician and engineer team)

* OEM service available (company owned R&D Team)

Packaging & Shipping

Exhibition

Company Profile

HangZhou Plent Machinery is located in HangZhou, the second largest seaport in China. We integrate scientific research, development, production, distribution and service. HangZhou PLENT Machinery is specialized at kinds of hose couplings and pipe fittings, including Camlock coupling, Storz coupling, Guillemin couplings, Universal Air Hose Coupling, KC Nipples & Hose Menders, Hose Clamps, Whip Check Safety Cables. Double Bolt Hose Clamps’ designing, developing and manufacturing.

HangZhou Plent Machinery is devoted to providing a “one-stop-solution” for our clients′ needs, from tooling design, aluminum or iron casting, machining and assembly in the areas of truck parts, pumps, valves, nozzles and fittings etc. So, we are a fully serviced company and able to save the cost and energy of the clients to the utmost.

We are ISO9001 and CCC certified. Good quality and Competitive prices are ensured by perfect testing equipment, quality inspection personals and selected chain suppliers. We are experienced in IP protection due to the innovation nature of the company. PLENT has become a preferred OEM supplier partnering with world leading company in US and Europe.

Distinguished as top-tie partner of companies to outsource their engineering service and manufacturing business, our service are featured by:

Small enough to care what you are

Strong enough to implement the right technologies for you

Lean enough to minimize the manufacturing costs

Experienced enough to use all the best practices and management expertise to run the facility

FAQ

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free if the cost is below USD20 with freight on your cost.

Q: How long is your delivery time?

A: Generally it is 5 days if the goods are in stock. Or it is 15 days if the goods are not in stock, it is according to quantity.

Q. what is your payment term?

A: T/T 30% payment in advance, balance to be paid prior shipment.

Q: what is your main market?

A: ,Western Europe,North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia.

Q: Can I have my own customized product?

A: Yes, we can supply logo Print and package desiged based in our MOQ.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Standard: | DIN, ANSI |

|---|---|

| Material: | Aluminium |

| Connection: | Casting |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

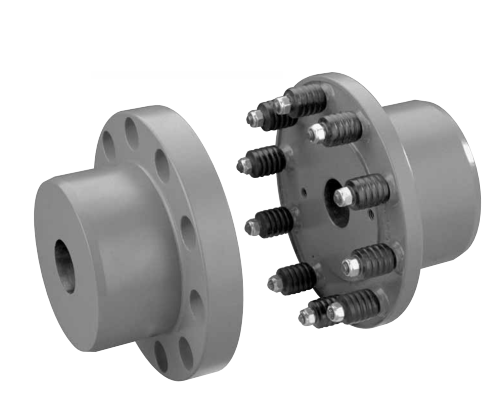

How Does a Pin Coupling Protect Connected Equipment from Shock Loads and Vibrations?

Pin couplings are designed to provide excellent protection to connected equipment from shock loads and vibrations, ensuring the smooth and reliable operation of the machinery. The unique features of pin couplings contribute to their ability to absorb and dampen shock loads and vibrations effectively:

- Flexibility: Pin couplings possess a certain degree of flexibility due to the presence of movable pins. When subjected to sudden shock loads or vibrations, the pins can flex and move slightly, absorbing the impact and preventing it from transmitting directly to the connected equipment. This flexibility helps in reducing stress and minimizing the risk of damage to the machinery.

- Torsional Compliance: The pin coupling’s design allows for a certain amount of torsional compliance. This means that when the connected shafts experience slight misalignments or angular displacements, the pin coupling can compensate for these variations without causing additional stress or vibration in the system. This feature ensures that the machinery remains in proper alignment even under dynamic conditions, reducing wear and tear.

- Damping Characteristics: The presence of movable pins introduces damping characteristics to the coupling. When vibrations occur in the system, the pins can dampen these oscillations, preventing resonance and the amplification of vibrations. This damping effect improves the overall stability and performance of the machinery.

- Strength and Resilience: High-quality pin couplings are constructed from durable materials with excellent fatigue resistance. This enables the coupling to withstand repeated shock loads and vibrations over an extended period without compromising its integrity. The strength and resilience of the pin coupling contribute to the protection of the connected equipment.

Overall, pin couplings are reliable and versatile components that can effectively protect connected equipment from shock loads and vibrations. Their flexibility, torsional compliance, damping characteristics, and robust construction make them suitable for various industrial applications where shock and vibration mitigation are essential for maintaining the health and longevity of machinery and equipment.

How Does a Pin Coupling Handle Angular, Parallel, and Axial Misalignment?

A pin coupling is designed to handle different types of misalignment, including angular, parallel, and axial misalignment. The unique construction of pin couplings allows them to accommodate these misalignments without compromising the efficiency and performance of the connected equipment.

1. Angular Misalignment: Angular misalignment occurs when the axes of the driving and driven shafts are not parallel but intersect at an angle. Pin couplings can tolerate angular misalignment because of their flexible and floating pin design. The two coupling halves are connected by a series of pins, which can pivot and move within the pin holes. This flexibility allows the coupling to bend slightly, adjusting to the angle of misalignment between the shafts.

2. Parallel Misalignment: Parallel misalignment happens when the axes of the driving and driven shafts are parallel, but they are laterally displaced from each other. Pin couplings can handle parallel misalignment to some extent due to the floating nature of the pins. The pins can move laterally within the pin holes, allowing the coupling to adapt to the offset between the shafts.

3. Axial Misalignment: Axial misalignment occurs when there is a linear displacement along the axis of one shaft concerning the other. While pin couplings primarily focus on handling angular and parallel misalignment, they may offer limited axial misalignment capabilities. The floating pins provide a small degree of axial movement, but excessive axial misalignment is best avoided to prevent additional stresses on the coupling.

It is important to note that while pin couplings can accommodate some degree of misalignment, excessive misalignment should be avoided to prevent premature wear and potential failure of the coupling and connected equipment. Regular inspection and maintenance can help identify and address any misalignment issues, ensuring the optimal performance and longevity of the pin coupling in power transmission applications.

Can Pin Couplings Handle Misalignment Between Shafts?

Yes, pin couplings are designed to accommodate a certain degree of misalignment between shafts in rotating machinery. They are considered flexible couplings, which means they can provide some degree of angular, parallel, and axial misalignment capability.

Pin couplings typically consist of two hubs, each connected to a shaft, and a central sleeve with pins that transmit torque between the hubs. The pins allow for a limited range of movement, which helps to compensate for slight misalignments between the shafts.

The angular misalignment capacity of a pin coupling is achieved through the bending of the pins. When the shafts are misaligned at an angle, the pins on one side of the coupling experience bending while those on the opposite side are in tension. The pins are designed to withstand these bending and tension forces within their elastic limits, ensuring proper functioning and longevity of the coupling.

Similarly, the pins can accommodate parallel misalignment by sliding within the pin holes of the coupling’s central sleeve. This sliding action allows the hubs to move slightly relative to each other, compensating for any offset between the shafts.

However, it is essential to note that pin couplings have limitations in terms of the amount of misalignment they can handle. Excessive misalignment beyond their specified limits can lead to increased wear on the pins and other coupling components, reducing the coupling’s effectiveness and potentially causing premature failure.

While pin couplings are suitable for applications with moderate misalignment requirements, they may not be the best choice for applications with significant misalignment or where precise alignment is critical. In such cases, more flexible couplings like gear or elastomeric couplings may be more appropriate.

Overall, when considering the use of pin couplings, it is essential to carefully evaluate the specific misalignment requirements of the application and select a coupling that can adequately accommodate those misalignments while ensuring reliable and efficient power transmission.

editor by CX 2023-10-01