Product Description

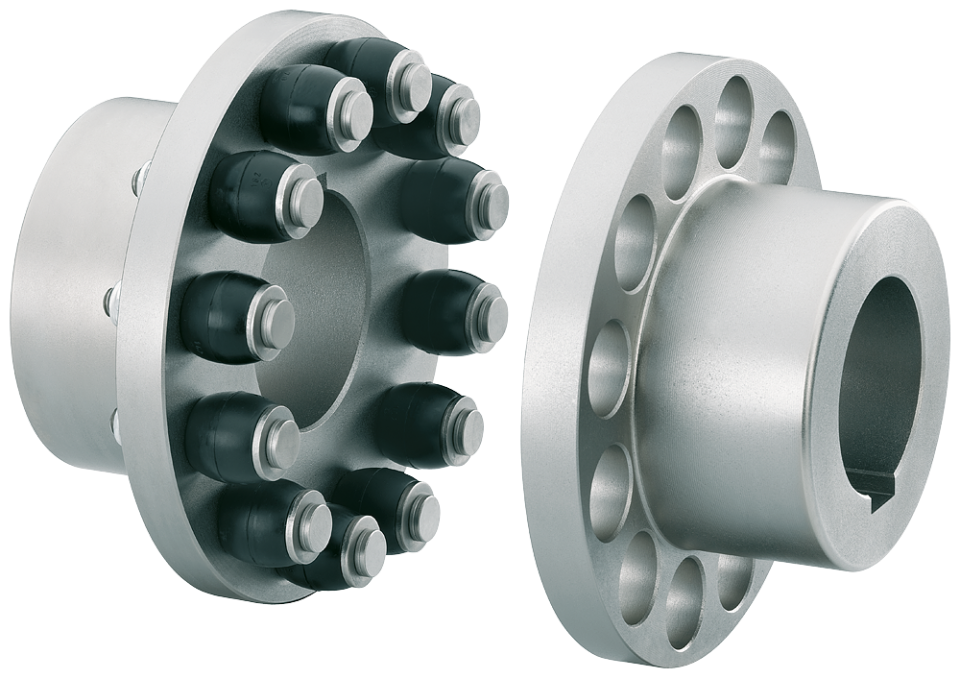

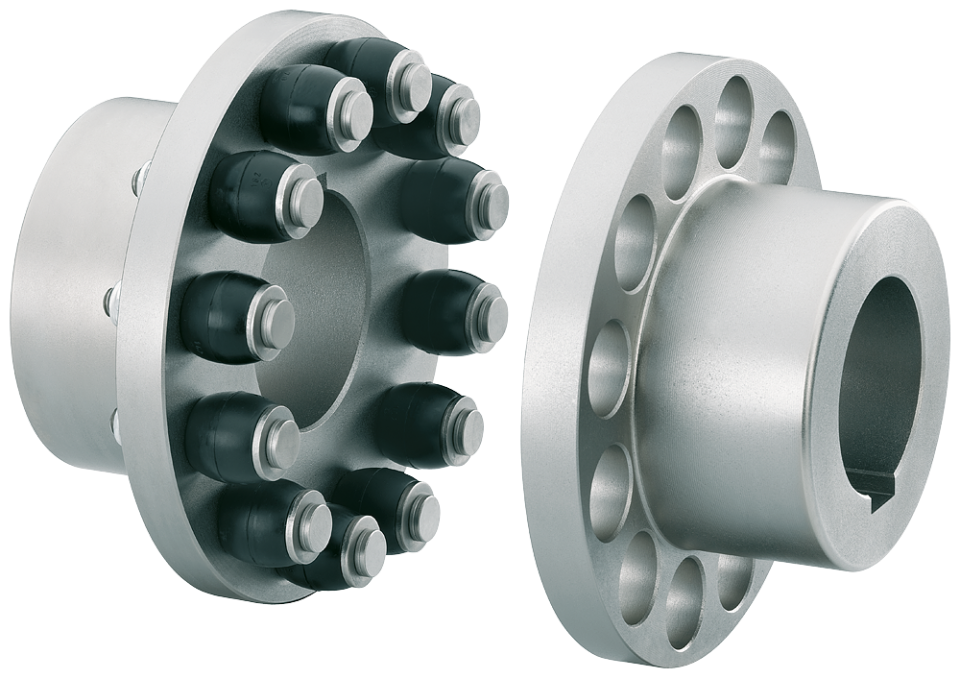

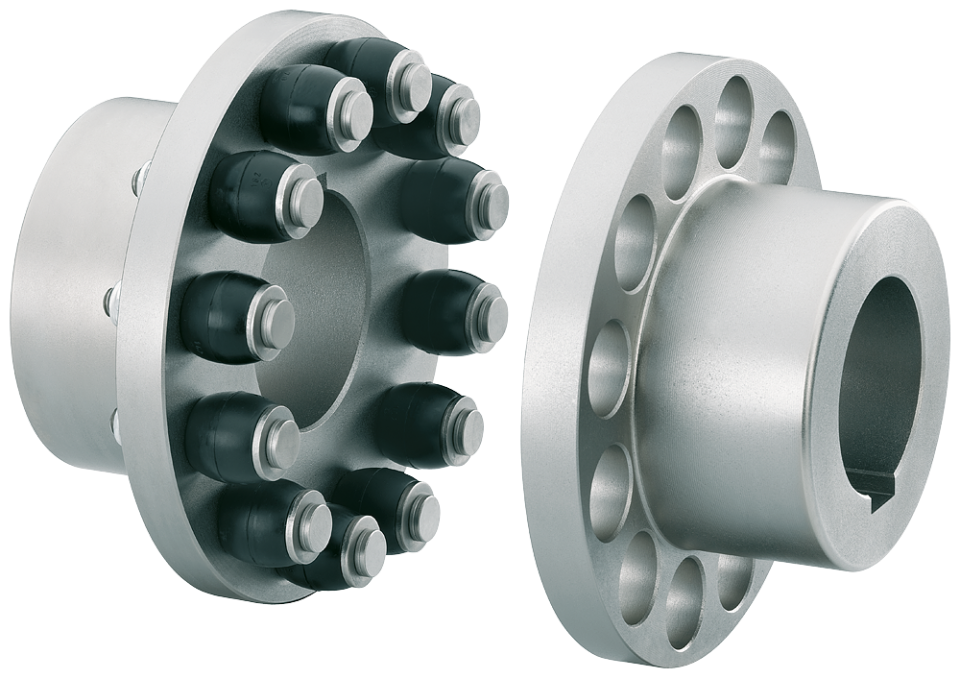

235 32K Excavator Coupling Machine Parts Track Pin Press Flexible Coupling

Basic information:

Model: 235 32K

Used on:Excavator, Air Compressor, Marine Machine

Packing: Plastic Bag, Carton

Coupling Type: Coupling Inserts

Material: Rubber, Iron

Payment Methods: Bank Transfer, Western Union, Money Gram, Credit

Coupling Structure: Helical Coupling

Supply Ability: 3000PCS Per Week

After-sales Service: Online Support

Coupling Structure: Helical Coupling

Products Parts:

| Pos. | Part No | Qty | Parts name |

| 1. | 9K-3115 | [1] | HEAD |

| 2. | 3P-1388 | LOCKWIRE 7.62 dm(30 in.) | |

| 3. | 2B-2955 | [4] | BOLT |

| 4. | 5K-1787 | [1] | SEAL |

| 5. | 7J-3322 | [1] | SEAL |

| 6. | 9K-3307 | [1] | PISTON |

| 7. | 9K-3304 | [1] | SEAL |

| 8. | 9K-9716 | [1] | HOUSING |

| 9. | 8S-2332 | [4] | BOLT |

| 10. | 9K-3148 | [1] | SHAFT |

| 11. | 8K-0507 | [4] | DISC |

| 12. | 8K-0509 | [5] | PLATE |

| 13. | 9M-5571 | [1] | SEAL |

| 14. | 9K-9715 | [1] | ADAPTER ASSEM. |

| 15. | 4D-0672 | [2] | DOWEL |

| 16. | 5J-2383 | [1] | SEAL |

| 17. | 8K-0508 | [2] | SPRING |

| 18. | 8K-571 | [2] | RETAINER |

| 19. | 1D-4623 | [4] | BOLT |

| 5H-1504 | [4] | WASHER | |

| 20. | 9K-3145 | [4] | BOLT |

| 21. | 9K-3305 | [1] | WASHER |

| 22. | 6B-3645 | [1] | SNAP RING |

| 23. | 4F-8824 | [1] | SEAL |

| 24. | 8K-2004 | [1] | SHAFT |

About us:

specialized in:

couplings, rubber mounts, gera parts, hydraulic seals and seal kits for hydraulic hammers, rock breakers, hydraulic excavators,wheel loaders, and JCB badkhoe loaders.

And, Our company also supply:

Engine parts, hydraulic piston pump and hydraulic travel motor, Swing motor assembly and hydraulic component parts, electric parts, etc. Hydraulic hammer breaker parts with piston, cylinder, chisel, through bolt, side bolt, top bush, front head bushing,accumlator, valve, etc.

We always try our best for all our customers and make it better and better. Welcome!

Products Show:

FAQ

| After-sales Service: | Online Support |

|---|---|

| Warranty: | Six Months |

| Type: | Coupling |

| Application: | Excavator |

| Certification: | CE |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

Can Pin Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, pin couplings can be used in both horizontal and vertical shaft arrangements. These couplings are designed to accommodate angular misalignment, parallel misalignment, and axial movement, making them versatile for various shaft orientations.

In horizontal shaft arrangements, where the shafts are aligned on the same horizontal plane, pin couplings can efficiently transmit torque while allowing for flexibility to accommodate minor misalignments and shaft movements. The pins and flexible elements in the coupling enable angular displacement and radial flexibility, ensuring smooth power transmission even if the shafts are not perfectly aligned.

In vertical shaft arrangements, where the shafts are aligned on a vertical plane, pin couplings can also be used effectively. The coupling design allows for axial movement, which is crucial in vertical applications where the shafts may experience expansion or contraction due to thermal changes or other factors. The flexible nature of pin couplings allows them to handle these axial movements without compromising the coupling’s performance.

Whether in horizontal or vertical arrangements, pin couplings are commonly used in various industrial applications, including pumps, compressors, conveyors, and other rotating machinery. They are known for their simplicity, ease of installation, and ability to provide reliable power transmission while accommodating misalignment and shaft movement.

When using pin couplings in either arrangement, it is essential to ensure proper alignment and regular maintenance to maximize their performance and service life. Additionally, considering factors like torque requirements, operating conditions, and environmental considerations will help in selecting the appropriate pin coupling for a specific application.

Can Pin Couplings Be Used for Both Motor-to-Shaft and Shaft-to-Shaft Connections?

Yes, pin couplings can be used for both motor-to-shaft and shaft-to-shaft connections in various mechanical systems. The versatile design of pin couplings allows them to connect two shafts with aligned or misaligned centers, making them suitable for a wide range of applications.

Motor-to-Shaft Connections: In motor-driven systems, pin couplings are commonly used to connect the motor shaft to the driven shaft of the equipment. The motor can be an electric motor, combustion engine, or any other type of power source. The pin coupling efficiently transfers torque from the motor shaft to the equipment’s driven shaft, enabling power transmission and mechanical motion.

Shaft-to-Shaft Connections: Pin couplings are also well-suited for shaft-to-shaft connections, where two separate shafts need to be joined together. This could be the case when extending the length of a shaft or connecting two separate pieces of rotating equipment. The pin coupling provides a secure and flexible connection between the two shafts, allowing torque to be transmitted between them while accommodating misalignment.

It is essential to consider the specific requirements of the application when selecting a pin coupling. Factors such as the amount of misalignment, torque capacity, operating conditions, and space constraints should be taken into account to ensure the coupling can effectively and reliably connect the motor and shafts.

Overall, the versatility and performance of pin couplings make them a popular choice for both motor-to-shaft and shaft-to-shaft connections in various industrial and mechanical systems.

Limitations and Disadvantages of Using Pin Couplings

While pin couplings offer various advantages and are suitable for many applications, they also have some limitations and disadvantages to consider:

- Misalignment Restrictions: Pin couplings can accommodate a certain degree of misalignment, but excessive misalignment can lead to increased wear and stress on the coupling components. They are not as effective at handling large angular or parallel misalignments compared to other flexible couplings like gear or elastomeric couplings.

- Less Damping Capacity: Pin couplings have limited damping capacity, which means they may not effectively absorb and reduce vibrations in the system. In applications where vibration damping is critical, elastomeric or flexible couplings may be more suitable.

- Noisy Operation: The rigid nature of pin couplings can lead to increased noise during operation, especially at high speeds or in applications with significant misalignment. This noise can be a concern in environments where noise levels need to be minimized.

- Higher Maintenance: Compared to maintenance-free couplings like certain types of elastomeric couplings, pin couplings may require more frequent inspection and maintenance. The pins and other components may experience wear over time and need replacement.

- Environmental Limitations: Some pin couplings may not be suitable for use in corrosive or high-temperature environments, depending on the materials used. Stainless steel or other corrosion-resistant materials can help mitigate this limitation.

- Size and Weight: In certain applications, the size and weight of pin couplings may be larger and heavier compared to other types of couplings. This can be a consideration in applications where weight is a concern or space is limited.

Despite these limitations, pin couplings remain a popular choice for many applications where their advantages, such as simplicity, durability, and cost-effectiveness, outweigh their disadvantages. It is crucial to carefully assess the specific requirements of the application and consider factors like misalignment, vibration, maintenance needs, and environmental conditions when selecting a coupling type.

editor by CX 2023-10-19