Product Description

We work on this product for more than 10 years and could supply 1 stop solution on the hose coupling and pipe fittings. We mainly supply these couplings to our customer. Such as Camlock coupling, Air hose coupling, Bauer coupling, fire fighting couplings ( Stroz coupling, Guillenmin couplings, John Morris couplings, Machino coupling, Barcelona coupling, Forest couplings, fire nozzles), pipe fittings(stainless steel pipe fittings, malleable iron pipe fittings, flanges, sanitary pipe fittings) and valves ( ball valve, gate valve, sanitary butterfly valve ) and so on.

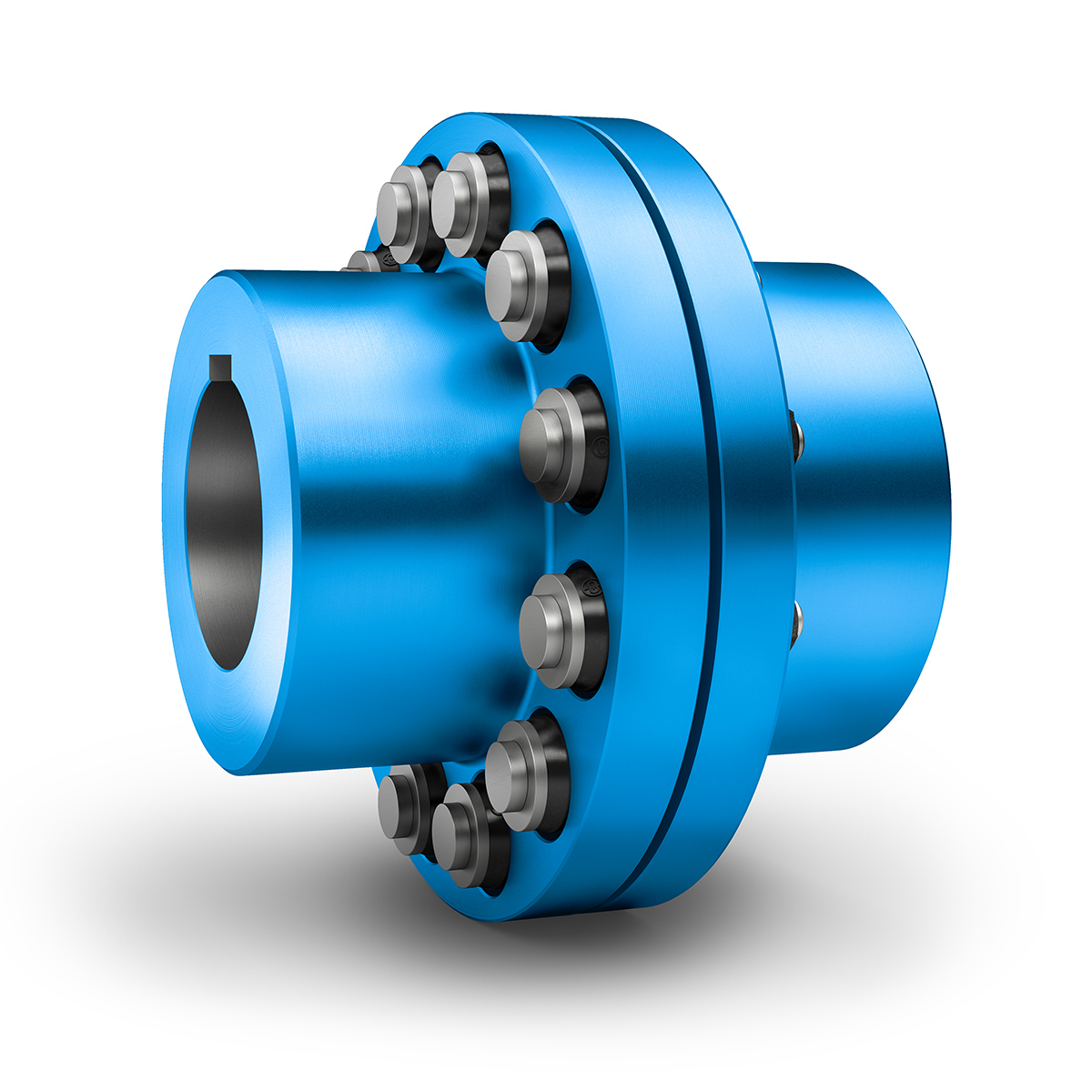

Adavantage of Pin Lug Fire Hose Coupling:

Good abrasion resistant, light weight, economical cost;

Save time compared with flanged or threaded fittings;

No tools needed and make the job easy;

Safety sealing for fluids, powders and pellets,Light weight and durable;

Could keep the transfers safe without any damage or any risks.

Detailed description:

| product | Aluminum Pin Lug fire hose coupling for fire hose/fire machine,/acoples de mangueras de bomberos |

| Key word | Aluminum Pin Lug fire hose coupling for lay flat hose, PVC fire hose connector, |

| Material | Aluminum and Brass, casting and forged |

| Size | 1-1/2″, 1-3/4″, 2″, 2-1/2″, 3″, 4″, 6″ |

| Thread | BSP, NPS |

| Method | forged method,aluminium die casting high pressure method |

| Pressure | working pressure: 16 bar Test Pressure: 24 Bar |

| Application | Firefighting, irrigation, petroleum, hydrocarbons, powders, chemicals |

| Place of origin | ZheJiang , China |

| Package | Plastic bag and Cartons then Pallet |

| advantage | quick, safey and no need tools |

| Delivery | By sea, By air and By express |

| Lead time | withinn 35-45 days after confiming the normal order |

Company Information:

Our customers:

Certification:

Main Products:

When you choose the camlock couplings, please confirm the details such as:

1, Types and Size

2, Material

3, Thread

4, Seals

5, Presuure and Tempreture

OUR SERVIC

Pre-sale service

1.We have stock and could deliver goods within short time.

2.OEM order are accepted, logo printing are available.

3.Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

4.All of our products are produced by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

After you choose:

1. We will check cheapest shipping cost and make invoice to you at once.

2. Check quality and package again, then send out to seaport at 1-2 weekdays after your payment

3. Email you the tracking no., and help to CHINAMFG the parcels until you signed them and update you the situation.

After-sale service

1.We are very glad that customers give us some suggestion for price and products.

2.If you have any question,please contact us freely by E-mail or Telephone or Whatsapp or Skpye.

FAQ

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge and need your side pay the cost of freight.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q. what is your payment term?

A: T/T 30% payment in advance, balance to be paid before shipment. or L/C. Or West Union, Paypal and Money Gram if little value.

Q: what is your main market?

A: North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe.

Q: Can I have my own customized product?

A: Yes, we can supply logo Print and package desiged based in our MOQ.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Connection: | Female |

|---|---|

| Structure: | Control |

| Flexible or Rigid: | Rigid |

| Material: | Alloy |

| Standard: | Standard |

| Size: | 11/2"-6" |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are There Any Safety Considerations When Using Pin Couplings in Rotating Machinery?

Yes, there are several safety considerations to keep in mind when using pin couplings in rotating machinery. These considerations are essential to ensure the safe and efficient operation of the equipment and to protect personnel working in the vicinity. Here are some key safety points to consider:

- Guarding: When installing pin couplings, it is crucial to provide adequate guarding around the coupling area. This helps prevent accidental contact with the rotating coupling components, such as pins and hubs, which could cause severe injuries.

- Maintenance and Inspection: Regular maintenance and inspection of the pin coupling are vital to identify any signs of wear, misalignment, or damage. Any worn or damaged components should be replaced immediately to prevent coupling failure, which could lead to sudden equipment shutdown or safety hazards.

- Proper Alignment: Ensuring precise alignment of the connected shafts is crucial to the safe operation of the pin coupling. Misalignment can lead to increased stresses and premature wear on the coupling components, resulting in potential failures.

- Torque and Speed Limits: Adhering to the manufacturer’s recommended torque and speed limits for the pin coupling is essential for its safe operation. Exceeding these limits can lead to overloading and failure of the coupling.

- Environmental Considerations: Take into account the operating environment when selecting a pin coupling. Extreme temperatures, corrosive atmospheres, or harsh conditions may require special materials or coatings to ensure the coupling’s integrity and prevent premature failure.

- Training and Awareness: Operators and maintenance personnel should receive proper training on the safe handling, installation, and maintenance of pin couplings. Awareness of potential hazards and safety protocols is crucial for the safe use of rotating machinery.

- Emergency Shutdown: Install emergency shutdown systems that can quickly stop the rotating machinery in case of any safety concerns or abnormal conditions.

- Compliance with Regulations: Ensure that the use of pin couplings complies with all relevant safety and industry regulations and standards.

By taking these safety considerations into account and implementing proper safety measures, the use of pin couplings in rotating machinery can be done safely and effectively, mitigating potential risks and ensuring a safe working environment for personnel.

Role of Pin Coupling in Reducing Downtime and Maintenance Costs

A pin coupling plays a crucial role in reducing downtime and maintenance costs in various mechanical systems and power transmission applications. Its design and features contribute to improved reliability and ease of maintenance, resulting in enhanced operational efficiency and cost savings. Here’s how pin couplings achieve these benefits:

1. Shock Absorption: Pin couplings are known for their ability to absorb and dampen shocks and vibrations generated during operation. By cushioning the impact of sudden loads or torque spikes, they protect the connected equipment from potential damage, reducing the frequency of unexpected breakdowns and downtime.

2. Misalignment Tolerance: Pin couplings can tolerate a certain degree of misalignment between shafts, such as angular and parallel misalignment. This flexibility allows for easier installation and alignment of equipment, saving time and effort during setup and reducing the need for precise alignment procedures.

3. Low Maintenance: Pin couplings are designed with simplicity in mind, often consisting of only two coupling halves connected by pins. This straightforward construction means fewer components that can wear out or require regular maintenance. Additionally, the flexibility of the pins helps reduce wear on the coupling and connected equipment, leading to longer maintenance intervals.

4. Easy Replacement: In the event of a failure or wear, pin couplings are relatively easy to replace compared to some other coupling types. The simplicity of their design allows for quick disassembly and reassembly, minimizing downtime during maintenance or replacement procedures.

5. Cost-Effective: The combination of low maintenance requirements and reduced downtime translates into cost savings for businesses. With fewer unexpected breakdowns and lower maintenance expenses, the overall cost of ownership for systems employing pin couplings can be more economical.

6. Reliability: Pin couplings are known for their reliability and durability. When properly selected and installed, they can provide long service life without frequent replacements, contributing to stable and consistent system performance.

By minimizing downtime, maintenance efforts, and associated costs, pin couplings are a preferred choice in various industrial applications. However, it is crucial to ensure that the pin coupling is correctly sized and installed, and regular inspections and maintenance are conducted to maximize its benefits and prevent premature failure.

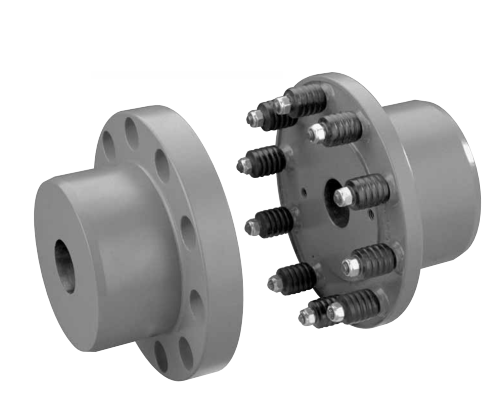

Can Pin Couplings Handle Misalignment Between Shafts?

Yes, pin couplings are designed to accommodate a certain degree of misalignment between shafts in rotating machinery. They are considered flexible couplings, which means they can provide some degree of angular, parallel, and axial misalignment capability.

Pin couplings typically consist of two hubs, each connected to a shaft, and a central sleeve with pins that transmit torque between the hubs. The pins allow for a limited range of movement, which helps to compensate for slight misalignments between the shafts.

The angular misalignment capacity of a pin coupling is achieved through the bending of the pins. When the shafts are misaligned at an angle, the pins on one side of the coupling experience bending while those on the opposite side are in tension. The pins are designed to withstand these bending and tension forces within their elastic limits, ensuring proper functioning and longevity of the coupling.

Similarly, the pins can accommodate parallel misalignment by sliding within the pin holes of the coupling’s central sleeve. This sliding action allows the hubs to move slightly relative to each other, compensating for any offset between the shafts.

However, it is essential to note that pin couplings have limitations in terms of the amount of misalignment they can handle. Excessive misalignment beyond their specified limits can lead to increased wear on the pins and other coupling components, reducing the coupling’s effectiveness and potentially causing premature failure.

While pin couplings are suitable for applications with moderate misalignment requirements, they may not be the best choice for applications with significant misalignment or where precise alignment is critical. In such cases, more flexible couplings like gear or elastomeric couplings may be more appropriate.

Overall, when considering the use of pin couplings, it is essential to carefully evaluate the specific misalignment requirements of the application and select a coupling that can adequately accommodate those misalignments while ensuring reliable and efficient power transmission.

editor by CX 2023-12-19