Product Description

Product Description

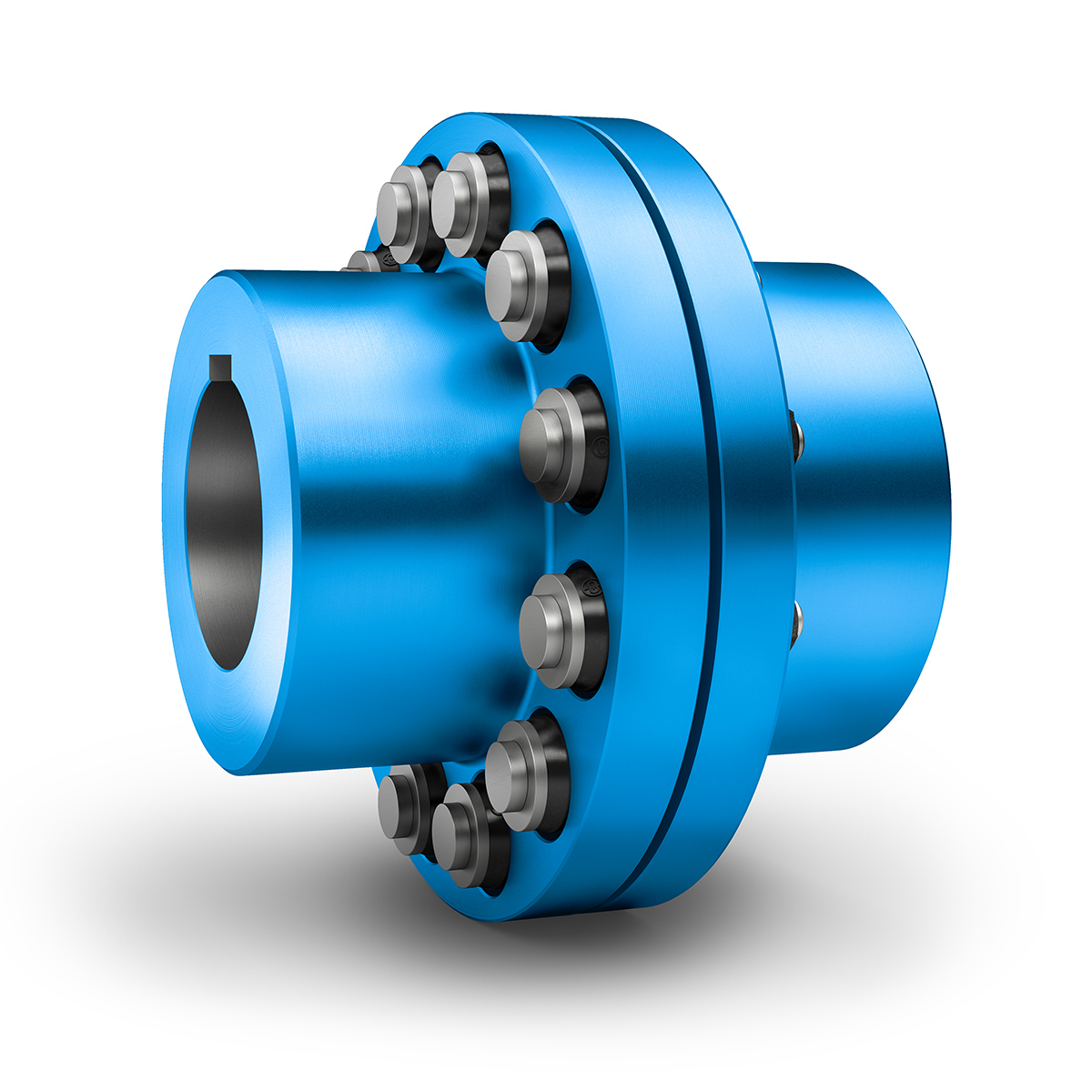

Coupling Pin

Scaffolding insert Coupling pin Scaffolding galvanized steel expansion joint pin connecting the frame system scaffold coupling Joint Pin,and also for tube conneting.

Product Parameters

| Name | Scaffolding Insert Coupling Pin |

| Size | 40*40mm |

| Unit Weight/kg | 0.52 |

| MOQ | 1000PCS |

| Samples | In stock |

| Surface | Electrical galvanized |

| Production ability | 20*20ft/Month |

| Material | Q235 |

| Package | Woven Bags with Wooden/Steel Pallets |

Detailed Photos

Packaging & Shipping

Company Profile

HangZhou CHINAMFG Tools Co.,ltd :products are infinitely customizable and available of many different types scaffoldings Our production stircly making as the buyers standard.

Main products for exportation:

1.Scaffoldings:Cuplock scaffolding,Ringlock scaffold,Kwikstage scaffold.Haki scaffold system.

2.Scaffold couplers:British type ,American Type,German Type and Australia and Itallian types.

3.Frames:Ladder type and door type,Layher frame,V shore frame,European frame,Italian frames.

4.Aluminum Plank ,Metal Plank ,which match with scaffoldings.

5.Scaffolding Props,Jack bases

6.Toe boards,Fence ,Metal pallets etc.

Our Advantages

1.In case there are unqualified materials from our , we bear 200% cost of the bad result.You will never loose money and will get our good ones as soon as possible.

2.Good payment term: 20% TT advance is acceptable and balance could be container arrive delivery port.

3.Fast delivery .4*40HC within 35days.

4.We keep developing new production together with you and your design always keep safe in our company ,

Contact me if you are looking CHINAMFG a trusted Chinese supplier.I am always here for you.

Our Exhibitions

CANTON FAIR

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 2 Years |

|---|---|

| Warranty: | 2 Years |

| Material: | Steel |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample frame scaffold coupling pin

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How Do Pin Couplings Compare to Other Types of Couplings in Terms of Performance?

Pin couplings offer certain advantages and disadvantages compared to other types of couplings, and their performance characteristics can vary depending on the specific application requirements. Below is a comparison of pin couplings with some commonly used couplings:

1. Gear Couplings:

- Flexibility: Gear couplings are more rigid than pin couplings and may not offer the same level of misalignment capacity.

- Torsional Stiffness: Gear couplings provide higher torsional stiffness, making them suitable for applications requiring precise torque transmission.

- Shock Absorption: Gear couplings can handle higher shock loads due to their robust design and greater stiffness.

- Maintenance: Gear couplings may require periodic lubrication and maintenance compared to maintenance-free pin couplings.

- Applications: Gear couplings are commonly used in heavy-duty and high-torque applications where precise torque transmission is essential.

2. Flexible (Elastomeric) Couplings:

- Flexibility: Elastomeric couplings offer higher misalignment capacity than pin couplings and can handle angular, parallel, and axial misalignment.

- Shock Absorption: Elastomeric couplings provide excellent shock absorption, damping vibrations, and protecting connected equipment.

- Torsional Stiffness: Elastomeric couplings have lower torsional stiffness compared to pin couplings, making them more forgiving in high shock load applications.

- Installation: Elastomeric couplings are easy to install and require no lubrication, making them maintenance-free.

- Applications: Elastomeric couplings are commonly used in pumps, compressors, and other machinery where vibration isolation is crucial.

3. Rigid Couplings:

- Torsional Stiffness: Rigid couplings provide high torsional stiffness, ensuring accurate torque transmission.

- Misalignment Capacity: Rigid couplings have little to no misalignment capacity and require precise shaft alignment.

- Applications: Rigid couplings are used in applications where precise alignment is essential, such as shaft-to-shaft connections in high-precision systems.

Conclusion:

Pin couplings strike a balance between flexibility and torsional stiffness, making them suitable for applications with moderate misalignment and shock loads. They are often used in general industrial applications, conveyors, and light to medium-duty machinery.

When selecting a coupling for a specific application, it is crucial to consider factors such as misalignment requirements, shock and vibration loads, torsional stiffness, maintenance needs, and the level of precision required. Each coupling type has its strengths and weaknesses, and the appropriate choice will depend on the specific demands of the application.

How Does a Pin Coupling Handle Angular, Parallel, and Axial Misalignment?

A pin coupling is designed to handle different types of misalignment, including angular, parallel, and axial misalignment. The unique construction of pin couplings allows them to accommodate these misalignments without compromising the efficiency and performance of the connected equipment.

1. Angular Misalignment: Angular misalignment occurs when the axes of the driving and driven shafts are not parallel but intersect at an angle. Pin couplings can tolerate angular misalignment because of their flexible and floating pin design. The two coupling halves are connected by a series of pins, which can pivot and move within the pin holes. This flexibility allows the coupling to bend slightly, adjusting to the angle of misalignment between the shafts.

2. Parallel Misalignment: Parallel misalignment happens when the axes of the driving and driven shafts are parallel, but they are laterally displaced from each other. Pin couplings can handle parallel misalignment to some extent due to the floating nature of the pins. The pins can move laterally within the pin holes, allowing the coupling to adapt to the offset between the shafts.

3. Axial Misalignment: Axial misalignment occurs when there is a linear displacement along the axis of one shaft concerning the other. While pin couplings primarily focus on handling angular and parallel misalignment, they may offer limited axial misalignment capabilities. The floating pins provide a small degree of axial movement, but excessive axial misalignment is best avoided to prevent additional stresses on the coupling.

It is important to note that while pin couplings can accommodate some degree of misalignment, excessive misalignment should be avoided to prevent premature wear and potential failure of the coupling and connected equipment. Regular inspection and maintenance can help identify and address any misalignment issues, ensuring the optimal performance and longevity of the pin coupling in power transmission applications.

Selecting the Appropriate Pin Coupling for a Specific Application

Choosing the right pin coupling for a specific application involves considering several factors to ensure optimal performance, reliability, and safety. Here are the key steps to select the appropriate pin coupling:

- 1. Determine the Application Requirements: Understand the specific requirements of the application, including torque and speed specifications, shaft sizes, and misalignment tolerances. Consider the operating conditions, such as temperature, humidity, and exposure to corrosive substances.

- 2. Calculate Torque and Power: Calculate the torque and power requirements of the application to determine the appropriate pin coupling’s torque capacity. Make sure to consider both steady-state and peak torque loads.

- 3. Consider Misalignment Tolerance: Evaluate the degree of misalignment expected in the system. Different pin coupling designs offer varying levels of misalignment tolerance. Choose a coupling that can accommodate the expected misalignment without compromising performance.

- 4. Select the Pin Coupling Type: Based on the application requirements, choose the appropriate pin coupling type – single pin, double pin, triangular pin, splined pin, or taper pin coupling. Each type offers different torque capacities and misalignment capabilities.

- 5. Check Material and Construction: Consider the materials used in the pin coupling’s construction. Common materials include steel, stainless steel, and alloy materials. The material should be suitable for the application’s environmental conditions and corrosion resistance.

- 6. Verify Safety Features: Ensure the selected pin coupling has safety features, such as a fail-safe mechanism to protect equipment from overload or shock loads. Safety is crucial to prevent damage to machinery and ensure operator protection.

- 7. Consult with Manufacturers or Engineers: If unsure about the best pin coupling for the application, consult with coupling manufacturers or mechanical engineers. They can provide valuable insights and recommendations based on their expertise.

By following these steps, you can select the appropriate pin coupling that matches the specific needs of the application, providing reliable and efficient power transmission while minimizing the risk of downtime and equipment failure.

editor by CX 2024-04-17