Product Description

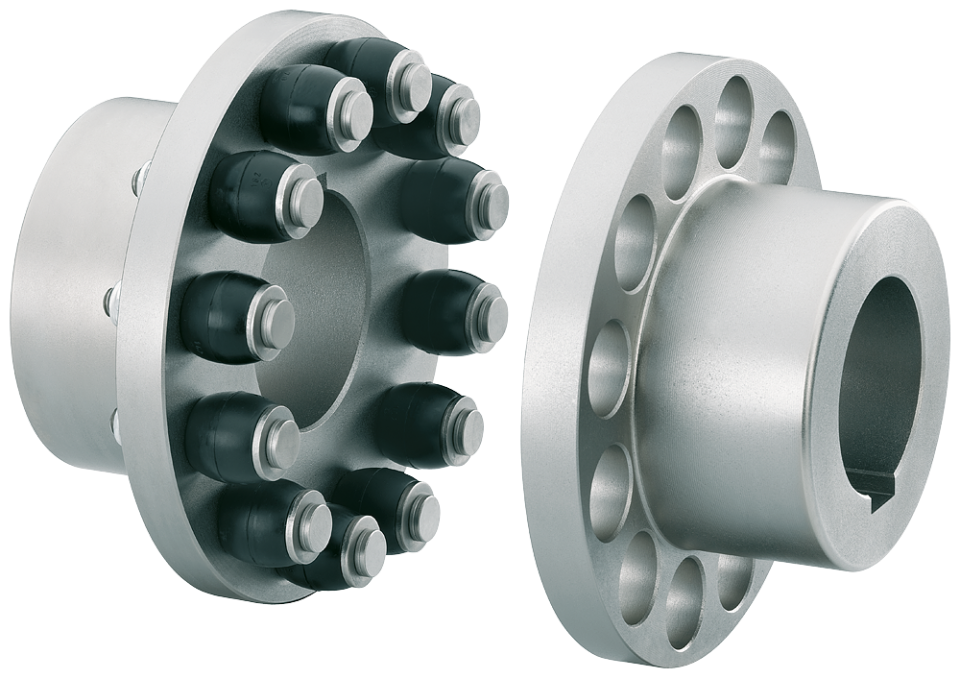

Cone Ring flexible coupling,

1. The coupling consists of 2 hubs: One pin hub with the corresponding pins and a bush hub.

2. The torque is transmitted via the steel pins with their taper elastomer rings and the corresponding bores

in the bush hub.

3. The couping is maintenance-free an is used in general engineering and the pump industry.

4. Customized requirement is available.

| size | Torque/Nm | Kw/100 RPM | Max Speed RPM |

| 571 | 50 | 0.56 | 6500 |

| 030 | 110 | 1.2 | 5470 |

| 038 | 190 | 2 | 5260 |

| 042 | 290 | 3 | 4750 |

| 048 | 480 | 5 | 4050 |

| 058 | 760 | 8 | 3600 |

| 070 | 1000 | 11 | 3220 |

| 075 | 2600 | 27 | 2730 |

| 085 | 3500 | 37 | 2480 |

| 105 | 5300 | 56 | 2100 |

| 120 | 9000 | 94 | 1880 |

| 135 | 12223 | 128 | 1660 |

| 150 | 16000 | 167 | 1520 |

ZheJiang Shine Transmission Machinery Co., Ltd is specialized in manufacturing and selling transmission products.

Our products are exported to the world famous machinery company in Europe, America, South Africa, Australia, Southeast Asia etc.

Our main products include: European pulley, American pulley, Couplings, taper bushing, QD bush, lock element, adjustable motor base, motor rail, sprockets, chain, bolt on hubs, weld on hubs, jaw crusher equipment & spare parts and all kinds of non-standardcasting products etc.

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 20/28mm |

| Torque: | 10-30N.M |

| Bore Diameter: | 20/28mm |

| Speed: | 6500 |

| Structure: | Flexible |

| Samples: |

US$ 0.00/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How Do Pin Couplings Compare to Other Types of Couplings in Terms of Performance?

Pin couplings offer certain advantages and disadvantages compared to other types of couplings, and their performance characteristics can vary depending on the specific application requirements. Below is a comparison of pin couplings with some commonly used couplings:

1. Gear Couplings:

- Flexibility: Gear couplings are more rigid than pin couplings and may not offer the same level of misalignment capacity.

- Torsional Stiffness: Gear couplings provide higher torsional stiffness, making them suitable for applications requiring precise torque transmission.

- Shock Absorption: Gear couplings can handle higher shock loads due to their robust design and greater stiffness.

- Maintenance: Gear couplings may require periodic lubrication and maintenance compared to maintenance-free pin couplings.

- Applications: Gear couplings are commonly used in heavy-duty and high-torque applications where precise torque transmission is essential.

2. Flexible (Elastomeric) Couplings:

- Flexibility: Elastomeric couplings offer higher misalignment capacity than pin couplings and can handle angular, parallel, and axial misalignment.

- Shock Absorption: Elastomeric couplings provide excellent shock absorption, damping vibrations, and protecting connected equipment.

- Torsional Stiffness: Elastomeric couplings have lower torsional stiffness compared to pin couplings, making them more forgiving in high shock load applications.

- Installation: Elastomeric couplings are easy to install and require no lubrication, making them maintenance-free.

- Applications: Elastomeric couplings are commonly used in pumps, compressors, and other machinery where vibration isolation is crucial.

3. Rigid Couplings:

- Torsional Stiffness: Rigid couplings provide high torsional stiffness, ensuring accurate torque transmission.

- Misalignment Capacity: Rigid couplings have little to no misalignment capacity and require precise shaft alignment.

- Applications: Rigid couplings are used in applications where precise alignment is essential, such as shaft-to-shaft connections in high-precision systems.

Conclusion:

Pin couplings strike a balance between flexibility and torsional stiffness, making them suitable for applications with moderate misalignment and shock loads. They are often used in general industrial applications, conveyors, and light to medium-duty machinery.

When selecting a coupling for a specific application, it is crucial to consider factors such as misalignment requirements, shock and vibration loads, torsional stiffness, maintenance needs, and the level of precision required. Each coupling type has its strengths and weaknesses, and the appropriate choice will depend on the specific demands of the application.

Role of Pin Coupling in Reducing Downtime and Maintenance Costs

A pin coupling plays a crucial role in reducing downtime and maintenance costs in various mechanical systems and power transmission applications. Its design and features contribute to improved reliability and ease of maintenance, resulting in enhanced operational efficiency and cost savings. Here’s how pin couplings achieve these benefits:

1. Shock Absorption: Pin couplings are known for their ability to absorb and dampen shocks and vibrations generated during operation. By cushioning the impact of sudden loads or torque spikes, they protect the connected equipment from potential damage, reducing the frequency of unexpected breakdowns and downtime.

2. Misalignment Tolerance: Pin couplings can tolerate a certain degree of misalignment between shafts, such as angular and parallel misalignment. This flexibility allows for easier installation and alignment of equipment, saving time and effort during setup and reducing the need for precise alignment procedures.

3. Low Maintenance: Pin couplings are designed with simplicity in mind, often consisting of only two coupling halves connected by pins. This straightforward construction means fewer components that can wear out or require regular maintenance. Additionally, the flexibility of the pins helps reduce wear on the coupling and connected equipment, leading to longer maintenance intervals.

4. Easy Replacement: In the event of a failure or wear, pin couplings are relatively easy to replace compared to some other coupling types. The simplicity of their design allows for quick disassembly and reassembly, minimizing downtime during maintenance or replacement procedures.

5. Cost-Effective: The combination of low maintenance requirements and reduced downtime translates into cost savings for businesses. With fewer unexpected breakdowns and lower maintenance expenses, the overall cost of ownership for systems employing pin couplings can be more economical.

6. Reliability: Pin couplings are known for their reliability and durability. When properly selected and installed, they can provide long service life without frequent replacements, contributing to stable and consistent system performance.

By minimizing downtime, maintenance efforts, and associated costs, pin couplings are a preferred choice in various industrial applications. However, it is crucial to ensure that the pin coupling is correctly sized and installed, and regular inspections and maintenance are conducted to maximize its benefits and prevent premature failure.

Limitations and Disadvantages of Using Pin Couplings

While pin couplings offer various advantages and are suitable for many applications, they also have some limitations and disadvantages to consider:

- Misalignment Restrictions: Pin couplings can accommodate a certain degree of misalignment, but excessive misalignment can lead to increased wear and stress on the coupling components. They are not as effective at handling large angular or parallel misalignments compared to other flexible couplings like gear or elastomeric couplings.

- Less Damping Capacity: Pin couplings have limited damping capacity, which means they may not effectively absorb and reduce vibrations in the system. In applications where vibration damping is critical, elastomeric or flexible couplings may be more suitable.

- Noisy Operation: The rigid nature of pin couplings can lead to increased noise during operation, especially at high speeds or in applications with significant misalignment. This noise can be a concern in environments where noise levels need to be minimized.

- Higher Maintenance: Compared to maintenance-free couplings like certain types of elastomeric couplings, pin couplings may require more frequent inspection and maintenance. The pins and other components may experience wear over time and need replacement.

- Environmental Limitations: Some pin couplings may not be suitable for use in corrosive or high-temperature environments, depending on the materials used. Stainless steel or other corrosion-resistant materials can help mitigate this limitation.

- Size and Weight: In certain applications, the size and weight of pin couplings may be larger and heavier compared to other types of couplings. This can be a consideration in applications where weight is a concern or space is limited.

Despite these limitations, pin couplings remain a popular choice for many applications where their advantages, such as simplicity, durability, and cost-effectiveness, outweigh their disadvantages. It is crucial to carefully assess the specific requirements of the application and consider factors like misalignment, vibration, maintenance needs, and environmental conditions when selecting a coupling type.

editor by CX 2023-10-03